Quick Leads

How Does the Thermal Conductivity of Aluminum Nitride PCB Compare to Other Materials?

Understanding Thermal Management in Electronics with Aluminum Nitride (AlN) PCBs

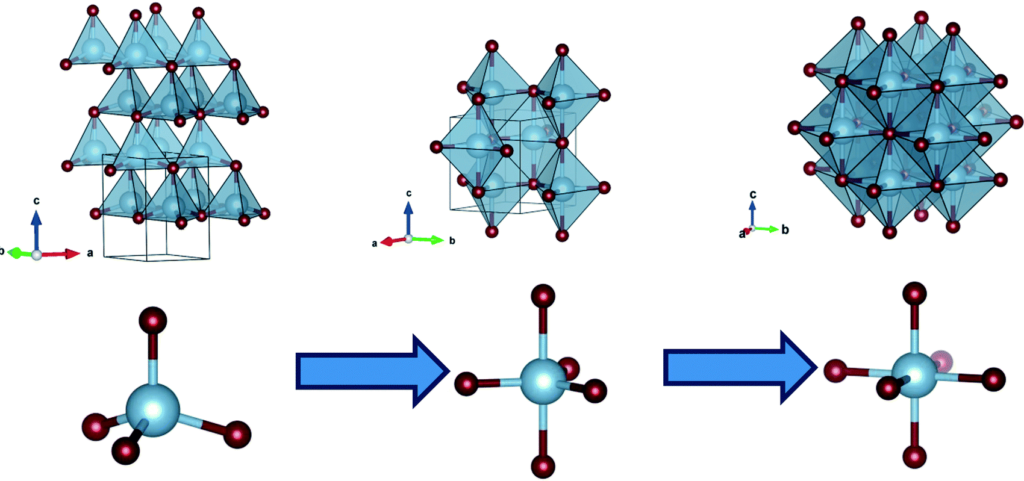

Why Does Aluminum Nitride Have High Thermal Conductivity?

Comparing Thermal Conductivity: AlN vs. Aluminum-Core vs. FR4

|

Material |

Thermal Conductivity (W/mK) |

Key Advantages |

Ideal Applications |

|

FR4 |

0.2 – 0.5 |

Economical, widely available |

General electronics |

|

Alumina |

20 – 30 |

High dielectric strength, good thermal performance |

Moderate-power applications |

|

Aluminum-Core |

1.0 – 8.0 |

Good for heat spreading, cost-effective |

LED lighting, power modules |

|

Aluminum Nitride |

170 – 200 |

Superior heat dissipation, low thermal expansion |

High-power applications, automotive, high-power LEDs |

Why Is Aluminum Nitride PCB Better for Heat Management?

Considerations When Choosing Aluminum Nitride PCBs

- Cost: AlN PCBs are usually more expensive than FR4 and aluminum-core options. If you want good heat dissipation, you have to pay for it. That’s why AlN is the best for applications where you really need to get rid of heat.

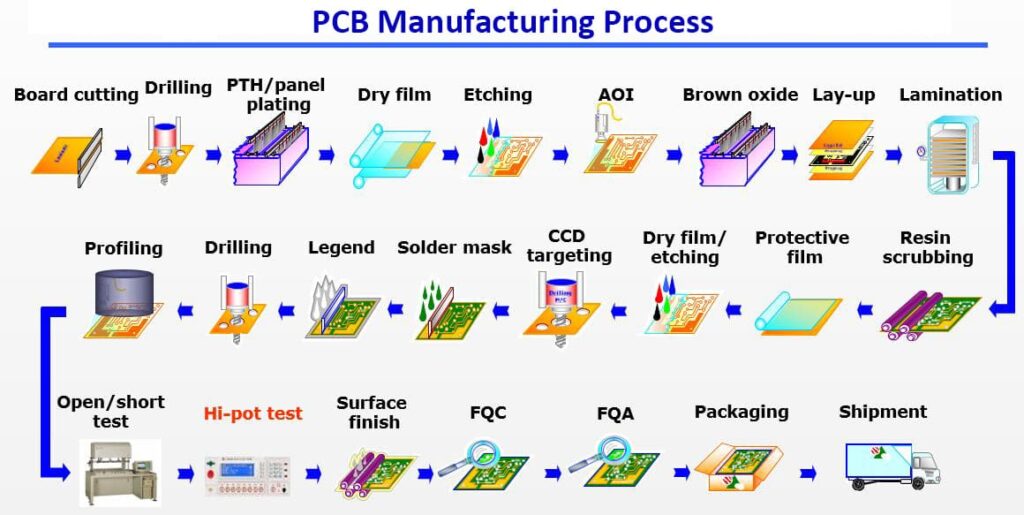

- Manufacturing Challenges: AlN is brittle, so you have to be careful with it when you’re making it. That can make things harder and more expensive.

- Application Fit: AlN is great for high-power and heat-sensitive applications. For lower power needs, you might want to look at aluminum-core or alumina substrates. They’re cheaper.

Is Aluminum Nitride PCB Worth the Cost for High-Power Electronics?

Cost-Benefit Analysis of AlN vs. Other Materials

Future Trends in Thermal Management

Sustainability and Lifespan Benefits of Aluminum Nitride

For more information, visit below:

Frequently Asked Questions (FAQs)

Aluminum Nitride PCBs are great for thermal management because they have high thermal conductivity, which ranges from 170 to 200 W/mK. That means they can get rid of heat really well, which keeps your components cool and prevents thermal stress. That’s especially important in high-power applications.

Yes, Aluminum Nitride PCBs are usually worth the cost for high-power or heat-sensitive electronics because they help you keep your operating temperatures stable and make your components last longer.

Their great thermal properties can justify the investment when you’re in an application where overheating can mess up how your stuff works and how long it lasts.

Aluminum Nitride has better thermal conductivity than both FR4 and alumina. FR4 has a conductivity of 0.2-0.5 W/mK and alumina has a conductivity of about 20-30 W/mK, while AlN has a conductivity of 170-200 W/mK. That’s why AlN is the best choice when you need to manage heat really well.

Aluminum Nitride PCBs are used in high-power applications where you need to manage heat well, like automotive electronics, high-power LEDs, power amplifiers, and IGBT modules. Those applications benefit from AlN’s high thermal conductivity and low thermal expansion.

When you’re thinking about AlN PCBs, you have to think about cost because they’re usually more expensive than FR4 or aluminum-core options. You also have to think about manufacturing because AlN is brittle, so it can be hard to work with. Finally, you have to think about whether AlN is the right fit for your application. It’s best for high-power or heat-sensitive applications.

Yes, using AlN can help with sustainability because it makes electronic devices last longer by managing heat well. That means you don’t have to replace them as often, which cuts down on electronic waste and helps the environment.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Considering AlN PCBs for Your Next High-Power Application?

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select the right transformer for SMPS, IoT, or relay control. Start designing smarter today.

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and delivery—and how turnkey EMS solutions protect your product and bottom line.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!