Quick Leads

Avoid Costly Mistakes in Selective Soldering: A Beginner's Guide

Selective soldering is a big deal in PCB assembly. It lets you solder certain components without messing up the whole board. If you’re new to selective soldering or you’re a small-time manufacturer, it’s important to know the basics of selective soldering.

This will help you avoid expensive mistakes that can lead to bad boards or hold up production. I’m going to walk you through the basics of selective soldering, the mistakes you need to avoid, and how to get the best results.

What is Selective Soldering?

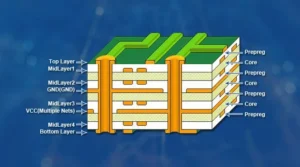

Selective soldering is a process that lets you solder through-hole components on a PCB without messing up other areas. Instead of flooding the whole underside of a PCB with molten solder like traditional wave soldering, selective soldering just focuses on certain areas using a controlled nozzle.

This precision is especially useful for boards that have a mix of through-hole and surface-mount components, where not all parts need to be soldered.

Benefits of Selective Soldering:

- Precision: Soldering only targeted components.

- Reduced Thermal Stress: Gentle on sensitive components.

- Efficiency: Better suited for complex PCB designs.

Key Components and Equipment for Selective Soldering

Using the right equipment is essential for successful selective soldering:

- Selective Soldering Machine: Controls the nozzle and PCB movement, ensuring precision.

- Flux Applicator: Ensures smooth solder flow by preventing oxidation.

- Preheating Station: Gradually warms the PCB, reducing thermal shock.

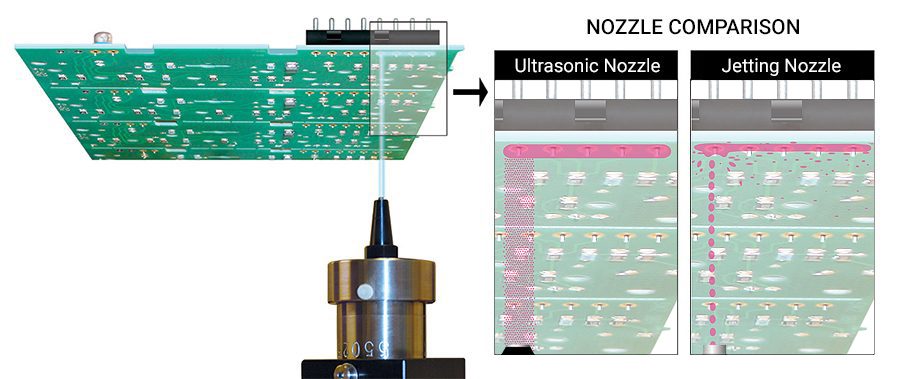

- Solder Nozzles: Available in different shapes and sizes for precise solder application.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Step-by-Step Selective Soldering Process

Follow these steps to set up and execute selective soldering effectively:

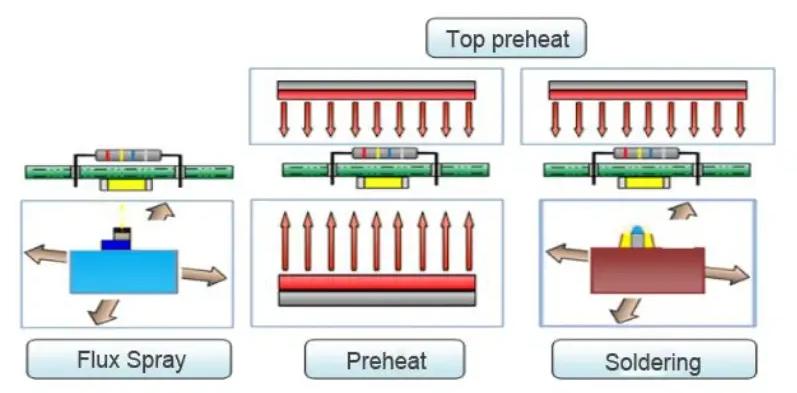

- Flux Application: Apply flux to the areas that need to be soldered. It helps prevent oxidation and ensures smooth solder flow.

- Preheating: Use a preheating station to warm up the PCB, minimizing thermal shock when solder is applied.

- Nozzle Adjustment: Adjust the nozzle’s height, angle, and temperature settings based on the size of the component and the thickness of the board.

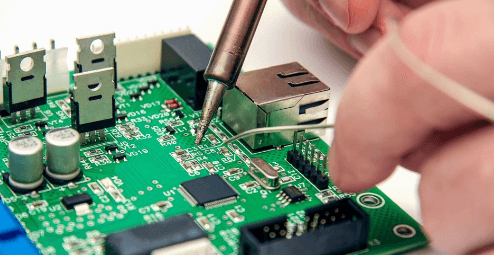

- Soldering Process: Watch the application to make sure the solder flows evenly and the joints look the same.

Pro Tip: Always adjust the angle of your nozzle based on the size of the components to ensure even solder flow.

Common Issues in Selective Soldering and How to Avoid Them

Selective soldering can be challenging when you’re starting out, but knowing what to watch out for can save you time and money:

- Over-application of Flux: Leads to residue buildup. Apply flux sparingly and ensure it’s evenly distributed.

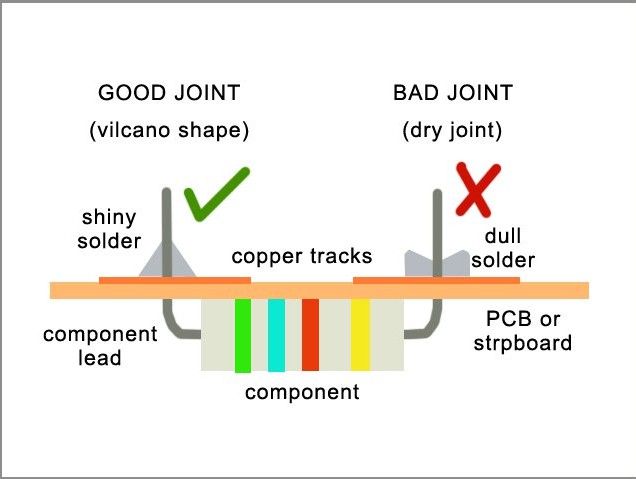

- Incorrect Nozzle Height: Can cause uneven solder flow. Adjust the height and angle carefully based on the component.

- Insufficient Preheating: Causes thermal shock and cracking. Always preheat for consistent results.

- Wrong Solder Alloy: Weak joints result from using incompatible solder. Choose the right alloy for your PCB’s materials.

How to Maintain Selective Soldering Equipment

Proper maintenance extends the lifespan of your soldering equipment:

- Clean Nozzles Regularly: Residue buildup can impact solder flow. Clean after every use.

- Check Flux Levels: Refill flux to avoid dry joints.

- Calibrate Your Machine: Maintain temperature and flow rates for consistent results.

A no-clean flux is usually the best choice for selective soldering because it means you don’t have to clean the board after soldering.

Comparison: Selective Soldering vs. Other Soldering Methods

Choosing the right soldering method depends on what you need to do. Here’s a quick comparison:

Method | Precision | Speed | Best For | Cost |

Selective Soldering | High | Moderate | Mixed-technology boards | High |

Wave Soldering | Low | High | Large batches | Moderate |

Manual Soldering | Moderate | Slow | Prototypes, Repairs | Low |

Contact us for personalized advice on selecting the right soldering method for your projects.

Choosing the Right Selective Soldering Machine

If you’re new to selective soldering or a small-scale manufacturer, choosing the right equipment is important. Here are some things to consider:

- Production Volume: Select a machine that matches your output needs.

- Board Complexity: More complex boards may need machines with finer control.

- Budget: Balance the initial cost of the machine with the benefits you’ll get from it, like reduced labor and material waste.

By choosing the right machine, you can increase your productivity and get consistent results.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

A no-clean flux is often the preferred choice for selective soldering because it minimizes the need for post-soldering cleaning.

Adjust the height and angle based on the size of the component, making sure the nozzle is close enough for precision without overheating.

Yes, you can use selective soldering for double-sided PCBs, especially if you have through-hole components on both sides.

Conclusion

Selective soldering is a powerful tool for precision PCB assembly, but there is a learning curve. If you follow this guide, learn the key steps, and avoid the mistakes, you can get good results and add selective soldering to your production.

Remember, practice and attention to detail are the keys to mastering this technique and reducing costly errors.

Discover how to avoid costly mistakes in selective soldering with our beginner’s guide. Get setup tips, common pitfalls, and best practices for PCB assembly.

🔧 Want to avoid these manufacturing issues with a trusted partner?

👉 See how our Turnkey PCB Assembly can help »

👉 See how our Turnkey PCB Assembly can help »

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!