Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Who Needs Box Build Assembly?

If you’re an OEM or hardware company developing products in industrial control, IoT, medical monitoring, or gas detection, chances are you’ll need more than just a populated circuit board.

You need a partner who can integrate PCBs into final enclosures, wire them, test them, and ship complete systems — that’s what box build assembly delivers.

This solution is ideal for:

-

Companies looking to scale production without building internal assembly lines

-

Engineers needing electronics contract manufacturing for OEMs

-

Teams seeking low-volume box build services to validate market demand quickly

What is Box Build Assembly?

Box build assembly refers to the system-level integration of a fully populated and tested PCB (Printed Circuit Board) into its final mechanical and electrical form. This can include:

-

Enclosure assembly (metal or plastic)

-

Cable and wire harness integration

-

Switches, displays, and connectors

-

Power supplies, batteries

-

Full functional testing and packaging

It’s a service commonly offered by electronics manufacturing service (EMS) providers, especially those with turnkey capabilities. The goal: deliver a ready-to-deploy product, not just a PCB.

What is Included in a Box Build?

A complete box build manufacturing solution often includes:

-

✅ PCB Assembly (PCBA)

-

✅ Component sourcing

-

✅ Enclosure integration (custom or off-the-shelf)

-

✅ Cable routing & internal wiring

-

✅ Mounting of sub-assemblies

-

✅ Software flashing or firmware upload

-

✅ Functional testing & calibration

-

✅ Final packaging and labeling

-

✅ Logistics coordination

Box Build Assembly Process Step by Step

Here’s a clear, 8-step breakdown of the box build assembly process:

-

Design Review & BOM Finalization

Engineering team validates your BOM, Gerbers, 3D enclosure files, and test plans. -

Component Procurement

Global sourcing of ICs, passives, connectors, wiring, and enclosures. -

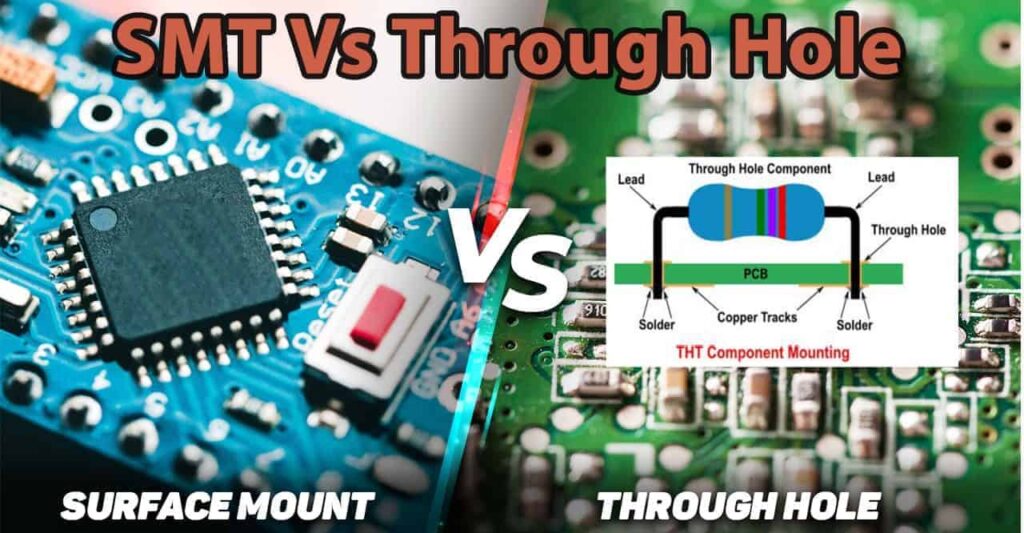

PCB Assembly

SMT and through-hole population. Optional lead-free soldering for RoHS compliance. -

Mechanical Assembly

Installing PCBA into housing with screws, adhesives, or clips. -

Cable Routing & Internal Wiring

Attaching internal connectors, sensors, external interfaces. -

Software Installation (If Required)

Flash firmware, run bootloader, and verify version control. -

Functional Testing & QA

Use test jigs or scripts to run real-world simulations. -

Packaging & Delivery

ESD-safe packing, barcode labeling, and shipping per Incoterms.

Box Build vs PCB Assembly: What’s the Difference?

PCB Assembly (PCBA) involves placing components onto a bare circuit board. It results in a semi-functional product that still needs to be housed, wired, and tested.

Box build assembly, on the other hand, includes everything after PCBA — the mechanical integration, internal cabling, final testing, and packaging. It delivers a complete product, ready for sale or deployment.

If you’re asking, “box build vs pcb assembly — which do I need?“, the answer depends on whether you’re shipping bare boards or full systems.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

Why Turnkey Box Build Solutions from China Are in Demand

Outsourcing to a china based electronics contract manufacturer offers major advantages:

-

🏭 Vertical Integration

One partner handles sourcing, PCBA, assembly, and shipping. -

💰 Cost Efficiency

Labor, overhead, and logistics are significantly lower. -

⏱ Faster Time-to-Market

Reduced delays from coordinating multiple vendors. -

📦 Scalability

Support from 10 units to 10,000+ units with the same team. -

🌍 Global Compliance

Providers like UnitCircuits offer RoHS-compliant PCB assembly from China to meet EU standards.

Common Challenges in Box Build Assembly

Even with good design, many teams face the following issues:

-

Supply Chain Complexity

BOMs include mixed suppliers, different lead times, inconsistent standards. -

Inconsistent Quality

Varying finishes, torque levels, or cable misrouting in low-volume builds. -

Engineering Misalignment

Lack of fit between PCB, enclosure, and fasteners due to unclear DFM. -

Regulatory Compliance

Delays from failed RoHS, CE, or UL tests. -

Minimum Order Restrictions

Many EMS providers won’t start a build under 500–1000 units.

How UnitCircuits Solves Box Build Challenges

✅ No MOQ Assembly for Flexibility

We support no MOQ box build assembly — perfect for pilot, NPI, and prototyping.

✅ Lead-Free, RoHS-Compliant Manufacturing

All units meet EU RoHS directives with lead-free soldering service and full traceability.

✅ Engineering Support Across Electrical + Mechanical

Our engineers optimize your stack-up, mechanical BOM, and help prevent early fit issues.

✅ Full Functional Testing for Every Unit

We design test jigs to ensure 100% pass rate on function and logic tests.

✅ Fast Turnarounds & Scalable Options

From 10 units to 10,000+, we provide fast box build manufacturing service that scales with your demand.

Custom Box Build Assembly for OEMs in Specialized Fields

We’ve supported a wide range of industries with custom box build assembly for OEMs:

| Application Area | Features |

|---|---|

| Gas Detection Systems | Rugged enclosures, sensor calibration, airflow control |

| Industrial IoT Gateways | Secure firmware upload, multi-interface (RS485, CAN, Modbus) |

| Medical Monitoring Devices | High-reliability, sterile handling, traceable serialization |

| Embedded Controllers | DIN rail housing, programmable logic, EM-shielded cases |

Functional Testing, Certifications, and Quality Assurance

Our box build and functional testing services ensure global reliability:

✅ Multi-Level Test Coverage

Includes ICT, FCT, burn-in, and EOL testing as needed.

✅ Test Jig Development

Custom test fixtures designed based on your use cases.

✅ Documentation & Reporting

We provide per-unit test logs and photos upon request.

✅ Certification Assistance

ISO9001, ISO13485, RoHS, CE, and UL supported.

Low Volume Box Build Services Without MOQ Limitations

✅ Ideal for Prototyping and Market Testing

No MOQ — test 5, 20, or 50 units with full-service integration.

✅ Transparent, Flexible Quoting

We give clear pricing on materials, labor, and tooling — no surprises.

✅ Rapid Iteration Support

Change mechanical or electrical specs between runs without delay.

Choosing the Right Box Build Service Provider in China

When evaluating a box build service provider in China, ask:

-

Do they offer complete turnkey service — from BOM to shipping?

-

Are they certified (ISO, RoHS, IPC-A-610)?

-

Can they handle quick builds without sacrificing quality?

-

Are they experienced with sustainable electronics manufacturing?

-

Is there dedicated engineering communication?

At UnitCircuits, we check every box — and have the systems to prove it.

✅ Still Have Questions?

Check out our Box Build Assembly FAQ or contact us for a free BOM review and quote.

FAQs

1. What are the consequences of misaligned PCB holes?

Misaligned holes cause assembly defects like:

❌ Components not fitting properly

❌ Solder joint failures

❌ Increased manufacturing rejects

Solution: Use tooling holes for precise hole placement during automated assembly.

2. Are through-hole components still relevant in modern PCBs compared to SMT?

Yes! While SMT dominates, through-hole components are still essential for:

✔ High-power applications (better current capacity, e.g., up to 10A)

✔ Rugged IoT devices (stronger mechanical hold, ideal for vibration-prone environments)

✔ High-reliability industrial electronics(e.g., aerospace systems)

Unit Circuits offers both TH and SMT assembly for optimal design flexibility:SMT Assembly & TH Assembly

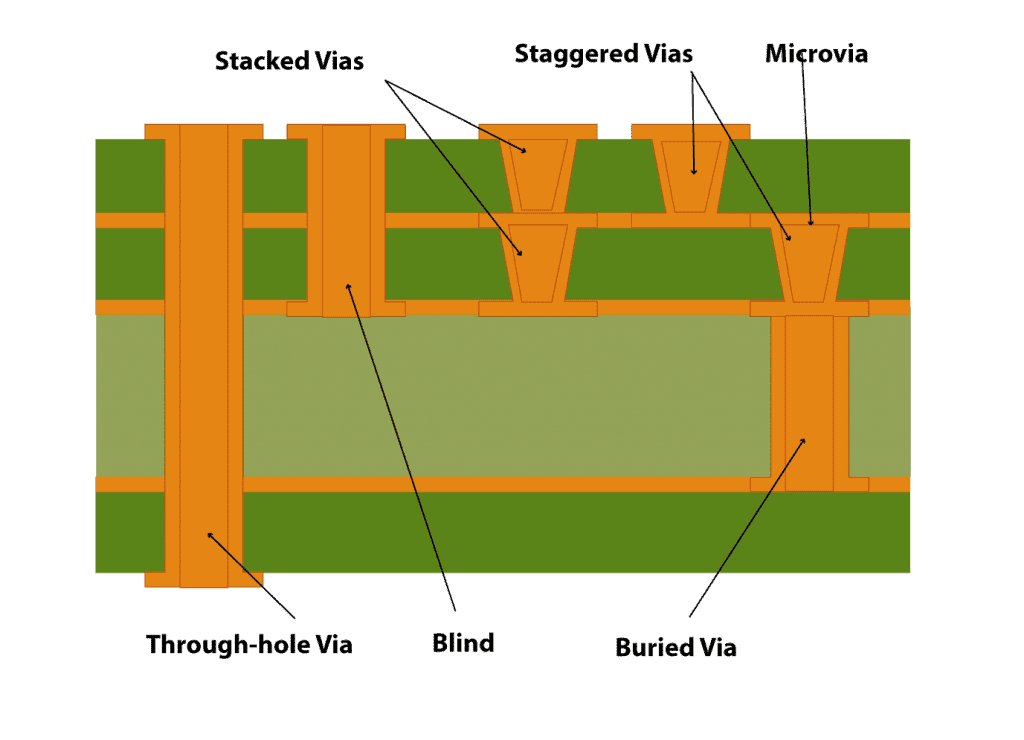

3. How do PCB holes affect signal integrity?

Poorly designed vias can cause signal reflections & EMI issues.

🔍 Solution: Use grounding vias & via stitching to reduce noise in high-frequency circuits.

Proper hole placement, size (e.g., 0.2mm-0.5mm for microvias), and shielding can minimize these effects. Our experts at Unit Circuits ensure optimal hole design for your PCB needs: PCB Manufacturing

4. How do PCB holes impact manufacturing costs?

💰 More drill hits = Higher costs

✔ Optimized hole placement reduces fabrication time

✔ Minimizing unnecessary via sizes lowers drilling costs

PCB holes increase costs due to drilling, plating, and inspection processes. Smaller holes (e.g., microvias) or higher densities raise expenses, but they improve performance. At Unit Circuits, we optimize hole designs to balance cost and quality, offering prototypes at $165 in 4 days.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary

Box build assembly is essential for companies wanting to turn circuit boards into finished products — fast. Whether you’re launching a new device or scaling production, UnitCircuits offers a trusted, turnkey solution that meets global standards and delivers on time. Ready to get started?

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!