Quick Leads-PCBA

🟢 Introduction: Box Build vs PCB Assembly – What’s the Difference?

Sourcing electronic manufacturing services can be overwhelming—especially when you’re unsure whether you need PCB assembly alone or full system-level integration. Many engineers and procurement teams overpay or delay production by choosing the wrong service. In this article, we break down the difference and help you choose the most cost-effective solution.

Before exploring box build vs PCB assembly, it’s crucial to understand what a PCBA is. Many buyers confuse bare boards with fully assembled units. This guide explains the key differences between PCB and PCBA — a useful foundation before diving into complete product integration.

The main difference between PCB assembly and box build is scope. PCB assembly (PCBA) involves soldering components onto a printed circuit board. Box build includes the PCBA and goes further—adding enclosures, cabling, wire harnesses, firmware installation, system-level testing, and final packaging. While PCBA delivers a functional board, box build delivers a complete product ready for end-use. Choosing the right one depends on whether you need just the circuit or the whole system.

Let’s walk through the technical, logistical, and commercial differences between these services—and how choosing the right one can reduce delays, cut costs, and improve time-to-market.

🟡 What’s the key difference between PCB assembly and box build?

At its core:

PCB Assembly (PCBA) = populating a bare board with components

Box Build = integrating the populated board into a finished product

Here’s a simple breakdown:

| Feature | PCB Assembly | Box Build Assembly |

|---|---|---|

| Components soldered on PCB | ✅ | ✅ |

| Enclosure Integration | ❌ | ✅ |

| Cable and Wire Harness | ❌ | ✅ |

| Firmware Installation | ❌ | ✅ |

| Functional/System-Level Testing | Basic testing | Full product validation |

| Final Packaging & Shipping | ❌ | ✅ |

| Use Case | Circuit board only | Ready-to-ship product |

Box build is the final step in complete electronics manufacturing services.

For a professional perspective, this guide from Levison Enterprises outlines how scope, complexity, and cost differ between PCB assembly and full box build.

What does a box build include beyond PCB assembly?

What does a box build include beyond PCB assembly?

Box build, also known as system-level assembly, includes:

Mechanical Enclosure Assembly

→ Housing, brackets, thermal managementWire Harness and Cabling

→ Internal connections, power lines, I/O portsFirmware Installation

→ Software loading into microcontrollers, EEPROMsProduct Labeling & Serialization

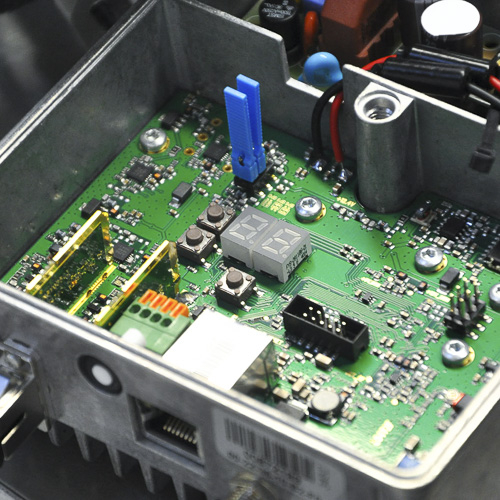

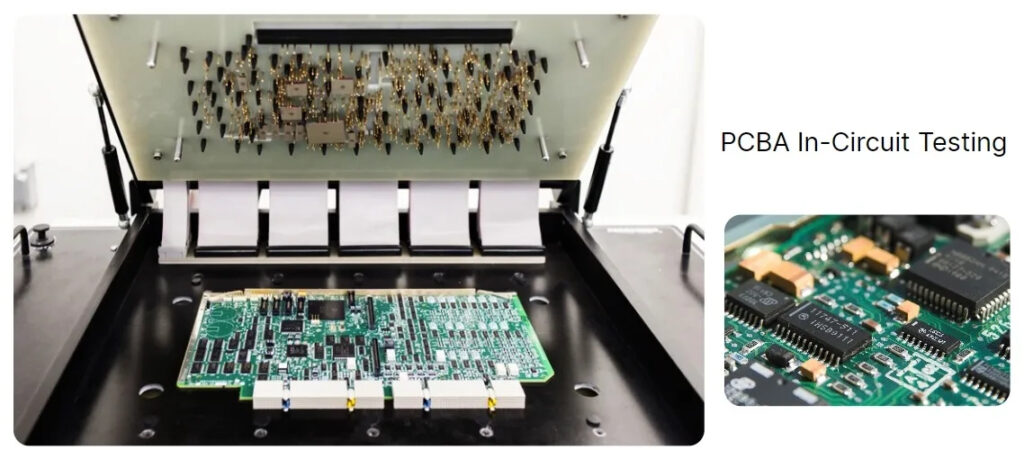

→ Custom labels, tracking codes, asset IDsQuality Testing of Electronics

→ Functional tests (FCT), burn-in, in-circuit test (ICT)Final Packaging & Shipping

→ Protective packaging, user manuals, accessories

These steps ensure your product is fully functional and market-ready—far beyond what standard PCBA provides.

PCB assembly involves specific and technical procedures including solder paste application, component placement, and quality inspections. For a full breakdown of the assembly process, check out these 10 essential PCB assembly steps every engineer should know.

As explained in this breakdown of box build assembly, box build goes well beyond PCBA to include mechanical housing, wiring, and complete system integration.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

⚖️ When do you need PCB assembly vs full box build services for electronics?

Choose PCB Assembly if you:

Have your own enclosure or integration team

Only need a working circuit board

Are prototyping subsystems

Choose Box Build if you:

Need a complete, assembled product

Lack in-house assembly capabilities

Want to reduce supply chain complexity

➡️ In many cases, PCB assembly with final box integration is the most efficient approach—especially when bundled with turnkey PCB assembly.

🧪 Box build vs PCB assembly for prototyping: What’s more efficient?

For prototyping, speed and flexibility are key. Here’s how the two compare:

| Factor | PCB Assembly Only | Box Build for Prototypes |

|---|---|---|

| Cost | Lower | Slightly higher |

| Complexity | Simpler | Moderate |

| Lead Time | Fast | Fast if turnkey partner is used |

| Design Feedback | Limited to board-level | Full product-level insights |

Using prototyping and box build together gives engineers faster validation at the system level—ideal for iterative design, IoT devices, or smart controllers.

Modern industrial assemblies benefit from advanced materials and modular system design—as highlighted in this Levison article on cable and box build integration.

💰 Why is box build assembly more expensive—and is it worth it?

Yes, box build costs more, but here’s why:

-

Additional components: screws, casings, cables, brackets

-

Skilled labor for integration & testing

-

Test fixtures and equipment

-

Packaging, compliance, and documentation

But the value?

-

Reduces errors from vendor handoffs

-

Accelerates time-to-market

-

Cuts rework and logistics costs

A properly managed box build saves money long-term.

📦 Low volume box build assembly: Ideal for custom electronics?

Absolutely. Low volume box build assembly is ideal for:

-

Industrial electronics

-

IoT and smart systems

-

Prototypes and pre-production runs

-

Medical or automotive instrumentation

Look for providers offering:

-

Flexible MOQ

-

Component sourcing

-

Functional testing

-

Product packaging and shipping

UnitCircuits supports full system integration—even in quantities as low as 1 unit.

🏭 Box build services for industrial electronics: What makes them different?

Industrial box builds need more:

Shielding & thermal protection

Robust connectors and housings

Compliance with CE, FCC, RoHS

Better functional and stress testing

We specialize in OEM electronics box build China operations tailored for industrial control systems, lab devices, and energy management products.

⚡ Fast box build and PCB manufacturing services: How to balance speed and quality

Speed is nothing without reliability.

Look for:

In-house testing + integration

Well-managed supply chains

Fast quoting tools and DFM review

On-time delivery with realistic lead times

At UnitCircuits, we offer fast quote electronics manufacturing and quick-turn integration without sacrificing quality or compliance.

🔒 OEM electronics box build in China: How to ensure compliance and IP protection

Concerns about IP and quality are real—but manageable.

We offer:

Non-disclosure agreements (NDAs)

Component traceability reports

RoHS-compliant PCB assembly from China

Documentation support for EU/US exports

With our sustainable electronics manufacturing process, OEMs get performance + peace of mind.

If you’re seeking a seamless approach that covers everything from PCB assembly to enclosure integration and shipping, explore why turnkey PCB assembly services are a game-changer. This model saves time, ensures consistency, and boosts product quality.

FAQs

1. What does “box built” mean in electronics manufacturing?

"Box built" refers to a product that has gone through complete system-level assembly. It includes the PCBA, enclosure, wiring, testing, and packaging, resulting in a fully functional, ready-to-use device. This term is often used in electronics box build services to describe turnkey or contract manufacturing solutions where the customer receives a plug-and-play product rather than just a board.

2. What is the difference between PCB and PCB assembly?

A PCB (Printed Circuit Board) is the bare board with no components mounted. PCB assembly (PCBA) involves placing and soldering components onto the PCB, making it function electrically. So, PCB is the structure, while PCB assembly adds the functionality. Understanding this difference helps avoid confusion when sourcing turnkey PCB assembly services.

3. What is a main PCB assembly in a product?

The main PCB assembly is the central circuit board that controls the core functions of a device. It often interfaces with secondary boards, sensors, and external modules. In system-level assembly, the main PCB is integrated into the full enclosure, making it a critical component of box build services for industrial electronics.

4. What is PCB assembly equipment and why does it matter?

PCB assembly equipment includes pick-and-place machines, reflow ovens, solder paste printers, and AOI testers. High-quality equipment ensures precise component placement, lead-free soldering, and reliable connections. Choosing a manufacturer with advanced assembly lines improves yield and consistency—especially critical for fast box build and PCB manufacturing services.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🟢 Conclusion:

Box build and PCB assembly serve different needs—but understanding the difference saves time, money, and stress. Whether you need a working board or a full product, we deliver reliable solutions with speed, flexibility, and care. Request a fast quote today to get started.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!