Quick Leads

Hybrid PCB Assembly: Overcoming Challenges When Combining SMT and THT

Find out the main challenges of hybrid PCB assembly and learn how to optimize your workflow, soldering methods, and inspection processes when combining SMT and THT.

Introduction

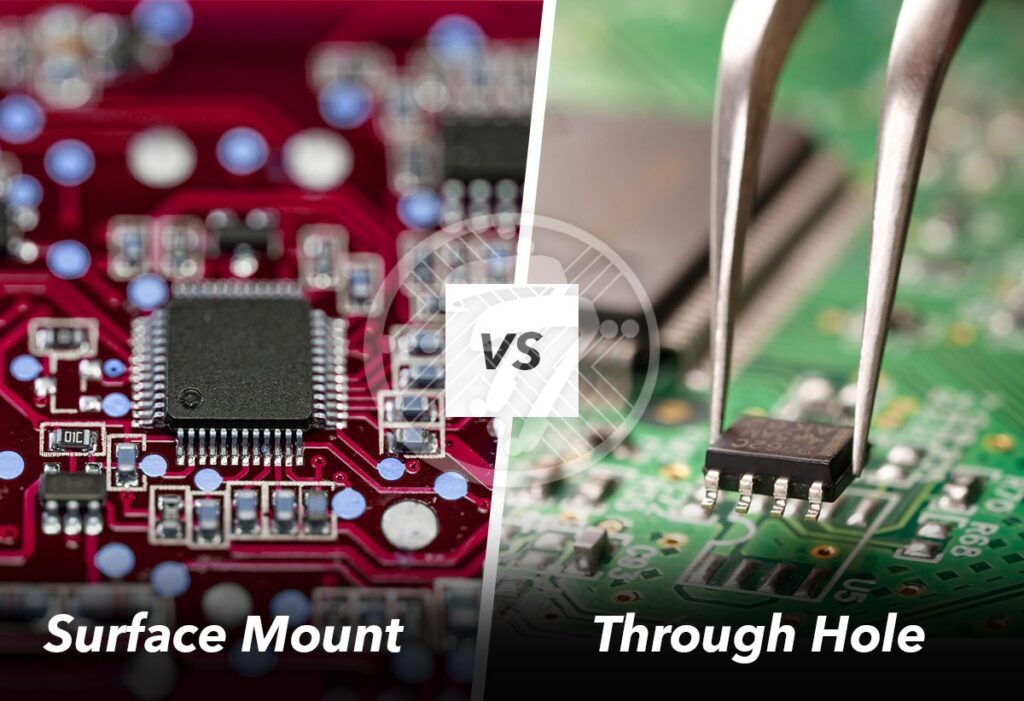

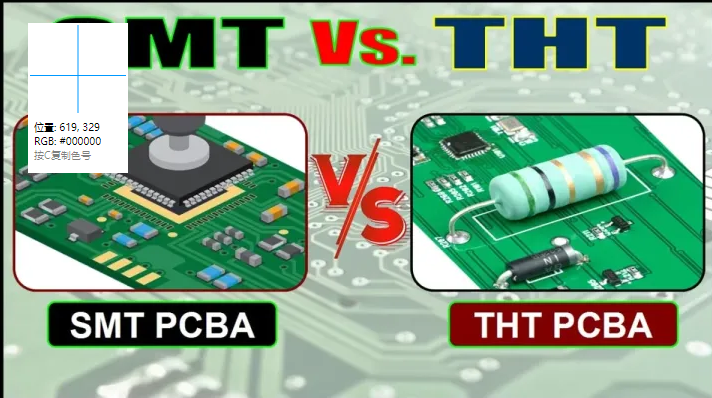

Combining surface mount technology (SMT) and through-hole technology (THT) in a single printed circuit board (PCB) gives you the best of both worlds: compact design and mechanical durability. But hybrid PCB assembly presents challenges in soldering, inspection, and production management that you need to overcome to achieve efficiency and quality.

Top Challenges and Practical Solutions for Hybrid PCB Assembly: SMT and THT Integration

Combining SMT and THT on a single PCB presents challenges such as incompatible soldering methods, complex inspection processes, and increased production costs.

To address these, manufacturers use hybrid soldering techniques, divide layout areas for easy assembly, and work with production teams early in the design process to optimize workflows and minimize costs.

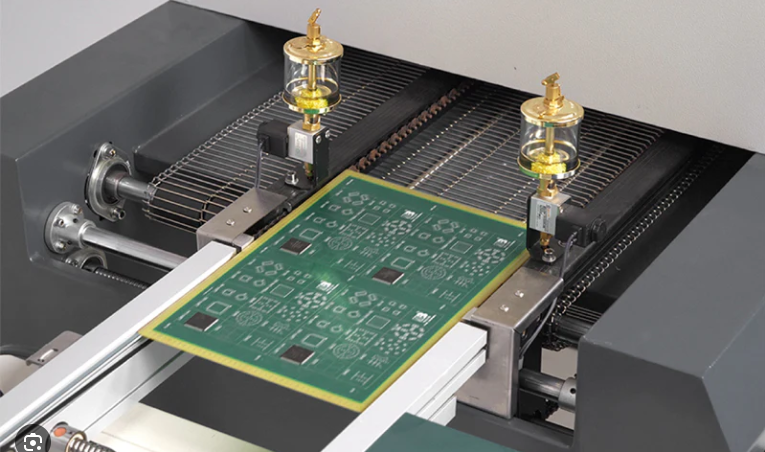

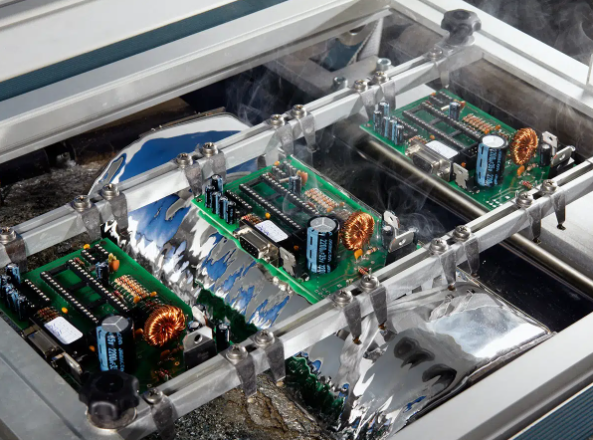

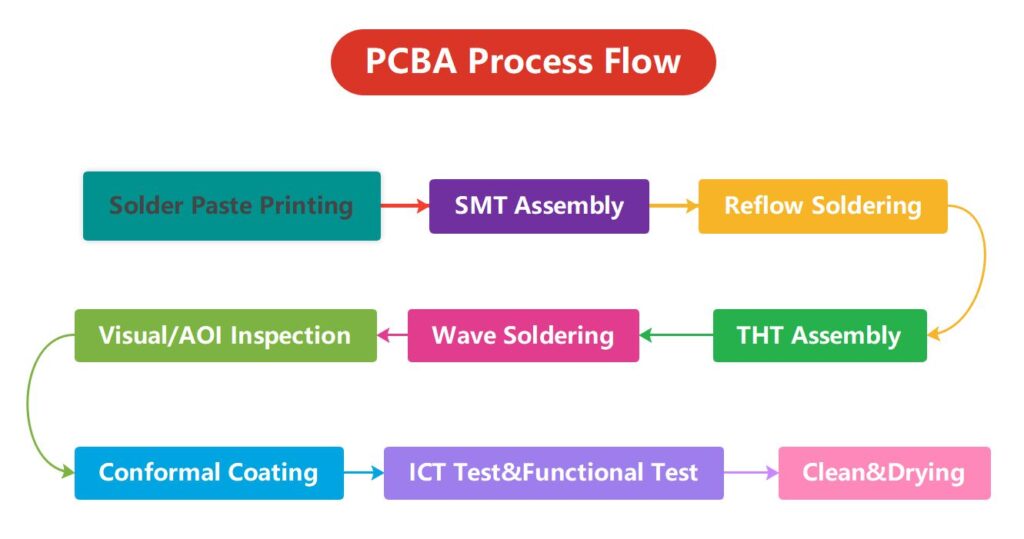

How to Deal with Soldering Problems in Hybrid PCB Assembly: Reflow vs. Wave Soldering

- Challenge: SMT components are soldered using reflow ovens, while THT parts are soldered using wave soldering. These two methods don’t play well together, which makes assembly more complicated.

- Solution: Most manufacturers do reflow first. They place and solder SMT components first, then insert THT parts for wave or selective soldering. This staged approach ensures high-quality solder joints for both technologies.

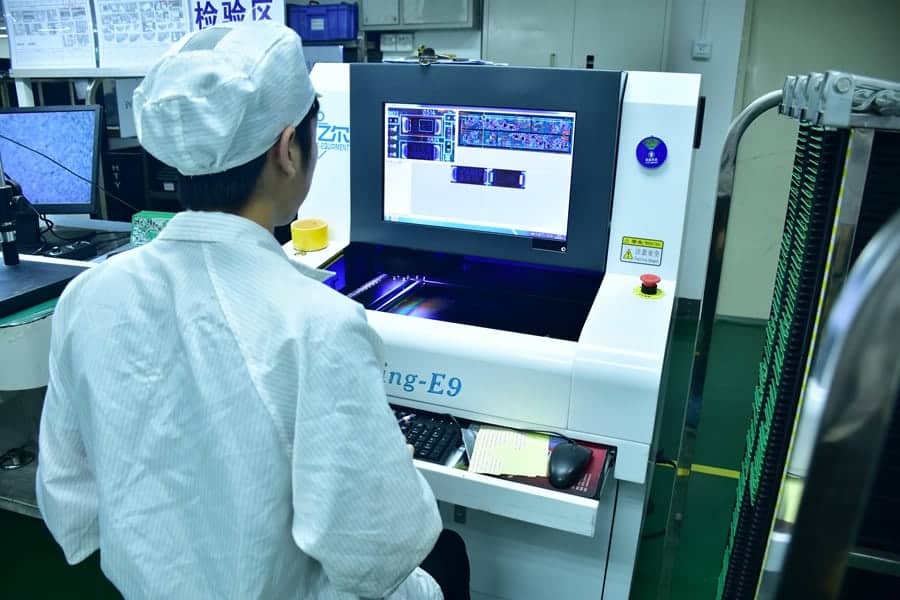

How to Optimize Quality Control: Inspection for SMT and THT Components

- Challenge: SMT components, such as BGAs, are difficult to inspect because of hidden solder joints, whereas THT components are easier to test but require manual inspection.

- Solution: We use Automated Optical Inspection (AOI)machines to check for problems with SMT parts, and people to check THT parts. We do both to make sure we catch everything.

How to Streamline Workflow: Assembly Sequence Planning for Hybrid PCBs

-

Challenge: Getting the order right for putting in SMT and THT parts is really important. If you don’t do it right, you’ll have problems, slow things down, and have to do things over again.

-

Solution: .Most companies do SMT first, then THT. They put the SMT parts on and solder them, then put the THT parts in by hand or wave solder them. This way, they don’t have to worry about things not lining up and slowing down production.

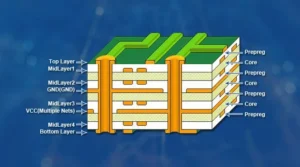

How to Optimize PCB Layout: Design Constraints in Hybrid Assembly

-

Challenge:When you have both SMT and THT parts on the same board, you have to plan your layout carefully. You have to make sure you have room for everything and don’t crowd the board. If you don’t do it right, you’ll have a hard time soldering everything and you’ll have more problems.

-

Solution:When you have both SMT and THT parts on the same board, you have to make sure you don’t have soldering overlap. You have to separate the areas where you’re going to put the SMT parts and the areas where you’re going to put the THT parts. This way, you can make the board faster and you’ll have fewer problems with it.

How to Minimize Costs and Lead Times in Hybrid PCB Production

-

Challenge: Hybrid assembly can cost more because you have to do special soldering and manual stuff. It can also take longer because you have to do more things.

-

Solution: If you work with your manufacturing team early on, you can avoid a lot of problems. You can make sure you don’t do things that will cost you money and you can make sure you get your boards on time.

THT vs. SMT: Which Technology is Best for Your Product?

|

Aspect |

SMT (Surface Mount Technology) |

THT (Through-Hole Technology) |

Hybrid Assembly |

|

Assembly Process |

Automated with reflow soldering |

Manual or wave soldering |

Combines both |

|

Component Size |

Small, lightweight |

Larger, robust |

Balanced for complex designs |

|

Best Use Case |

Compact consumer products |

High-stress mechanical components |

Complex designs with diverse needs |

|

Key Advantage |

Cost-effective automation |

Strong mechanical durability |

Flexibility and functionality |

Additional Considerations for Product Designers and OEMs

- Impact on Performance:

- SMT parts are small and light. They’re good for high-frequency signals, like the ones you find in consumer electronics and IoT devices.

- THT parts are bigger and stronger. They’re good for connectors, mechanical support, and things that get beat

- Supply Chain Management:Hybrid assembly means you have to get both SMT and THT components, which can make it harder to get parts. If you have good suppliers, they’ll make sure you get your parts on time and your production goes smoothly.

Key Takeaways

- Combining SMT and THT gives you flexibility in design but it makes soldering, inspection, and assembly harder.

- Hybrid soldering strategies, such as reflow-first workflows, ensure efficient production.

- Getting design and production teams together early helps you streamline processes, save money, and get stuff out the door on time.

- Hybrid PCBs are great for complicated designs because they let you mix tiny SMT parts with big, tough THT parts.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

To get the best of both worlds: SMT gives you small size and high-speed signal handling, while THT gives you mechanical strength and durability.

Use a reflow-first strategy: Place and solder your SMT components first, and then insert and solder your THT parts either by hand or with wave soldering.

Conclusion

When you know how to do it right, combining SMT and THT technologies on one PCB opens up a whole new world for engineers and designers. Hybrid PCB assembly gives you the best of both worlds: small size and mechanical strength. That’s why it’s perfect for complex electronic products.

If you get your design and production teams working together from the beginning, you’ll have a smooth assembly process, lower costs, and high-quality products.

Need expert help to optimize your hybrid PCB design? Contact us today for custom solutions and flawless production!

🔧 Want to avoid these manufacturing issues with a trusted partner?

👉 See how our Turnkey PCB Assembly can help »

👉 See how our Turnkey PCB Assembly can help »

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!