Quick Leads

What are the most common mistakes beginners make when repairing circuit boards

A lot of electronics hobbyists and students get excited to fix circuit boards, but they forget important steps that can mess up their repairs. If you don’t know what you’re doing or you don’t have the right tools, it’s easy to mess up and make things worse.

But with some help, you can avoid those problems. This article talks about the most common mistakes beginners make when they fix PCBs and how to fix them.

The most common beginner PCB repair mistakes include a lack of understanding of the PCB design, using inadequate tools, improper soldering, overlooking loose connections, and ignoring safety precautions. Additionally, failing to diagnose the root cause, using incorrect replacement parts, and not cleaning the circuit board are critical errors that can affect repair success.

Let’s look at these mistakes in more detail and see how you can avoid them to get better at fixing circuit boards.

What Are Common Problems When Troubleshooting a Circuit Board?

One thing beginners often miss is figuring out what’s wrong with the connections, like if parts are loose or if there’s leftover flux on the board after you solder. These problems can make your repair look good at first, but then stuff starts acting up again. For example, leftover flux can mess up the board, and loose parts can make bad connections that cause short circuits or electrical noise.

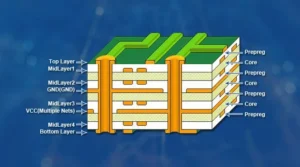

Lack of Proper Understanding of the Circuit Board

If you don’t know what each part does or where it goes, you might put the wrong parts in or mess up the wiring, which can make things worse.

Knowing what each part of the PCB does is really important for fixing stuff right. If you don’t know what’s wrong, you can’t fix it, so it’s important to get to know how the circuit is set up.

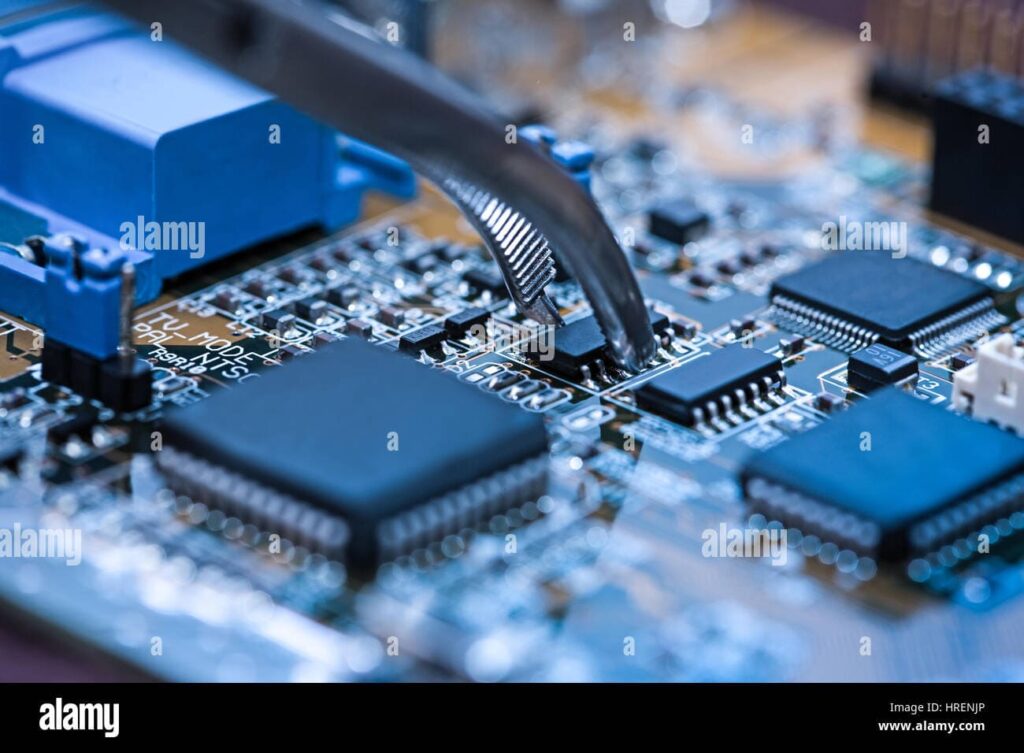

Inadequate Tools and Equipment

A lot of beginners try to fix stuff without the right tools, like a bad soldering iron, the wrong cleaning stuff, or no way to take parts off the board. If you don’t have good tools, it’s hard to fix stuff right, and you might mess things up or make them worse.

Choosing the best tools for PCB repair is essential for accurate results. Some recommended tools for beginners include:

- Fine-tip soldering iron

- Multimeter

- Desoldering pump

- Flux cleaner

Having the right tools makes precise and safe work possible.

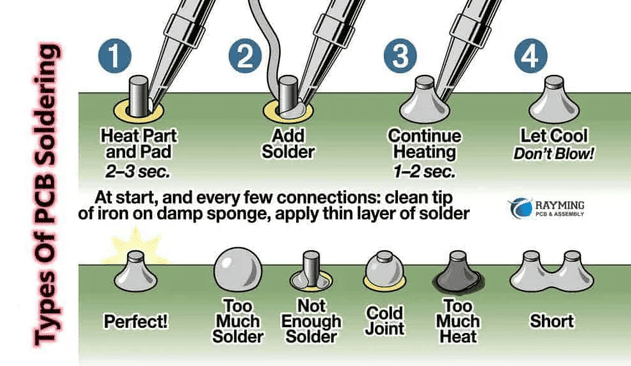

Improper Soldering Techniques

Bad soldering is one of the biggest problems. If you don’t heat up the solder enough, use too much, or don’t heat up the parts enough, the connection can be weak and break later. Beginners often hurry or don’t wait for the solder to melt right. To make a good connection, you need clean stuff, the right heat, and the right amount of solder.

Common Soldering Mistakes:

- Cold solder joints.

- Applying too much or too little solder.

- Insufficient heating during the soldering process.

Using Incorrect Replacement Parts

One thing beginners do a lot is put in a part that doesn’t work with the board, which makes things worse. Even if it looks like the same part, it might not be right, and the board can stop working or get messed up. Always make sure the new part is the same as the old one, and check the board’s plan to make sure you got it right.

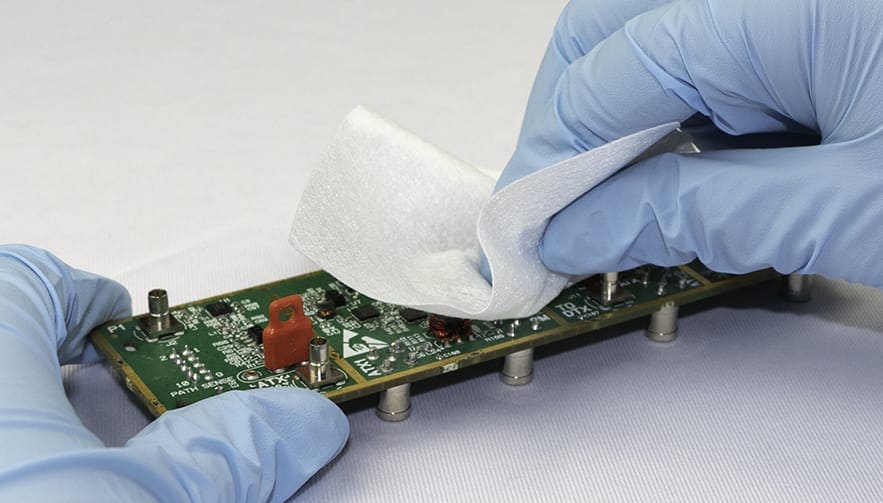

Failure to Clean the Circuit Board

If you don’t clean off the flux or junk from the board after you solder, you can get short circuits or other problems. After you solder, you have to clean the board so you don’t make a path for electricity across the solder joints. A clean board also makes sure the electricity flows right and makes it easier to look at the board and see if anything’s wrong. Use isopropyl alcohol to remove any flux or dirt left after repairs.

Ignoring Safety Precautions

It’s really important to be safe when you work with electronics. Beginners might forget to turn off the power, wear safety stuff, or check for charged capacitors, which can be dangerous.

Before you fix anything, make sure the board isn’t getting power and the capacitors don’t have any electricity in them. Also, wear an anti-static wristband so you don’t mess up the sensitive parts.

How to Repair a Circuit Board?

To fix a PCB right, you have to figure out what’s wrong, take off the bad parts, and clean the area before you solder.

Steps to Repair a Circuit Board:

- Gather tools and materials, including soldering iron, solder, flux, and cleaning supplies.

- Remove the damaged component carefully using desoldering tools.

- Clean the solder pads to remove old solder and debris.

- Solder the replacement component using proper soldering techniques.

- Test the board to ensure it functions correctly.

Following these steps ensures a successful repair and extends the life of the board.

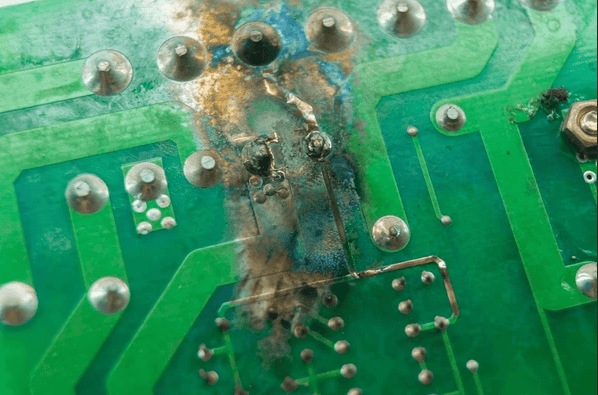

What to Look for on a Damaged Circuit Board?

Always look for stuff that’s messed up, like burn marks, parts that are swollen, or solder that’s in the wrong place. These can show that the board got too hot or that something’s wrong with the electricity, and you need to fix it right away. If you see stuff like wires that are broken, parts that are squished, or connections that are loose, the board might not work right.

For more information, visit below:

For more insights on common mistakes beginners make when repairing circuit boards, check out: repairing-circuit-boards

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Fixing circuit boards can be hard for beginners, but if you don’t make these common mistakes, it’s easier to fix stuff. If you have the right tools, do it right, and pay attention to the details, you can fix even hard stuff without worrying. Take the time to learn, practice your soldering, and make sure you’re safe when you work with electronics.

Need more guidance on PCB repairs? Contact us today for expert advice, or explore our services for your electronics manufacturing needs!

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!