Quick Leads-PCBA

Breaking into the supply chain of a major global brand like Decathlon isn’t easy—especially when you’re a small-batch electronics manufacturer competing in a fast-moving industry. But in mid-2025, we were able to deliver a successful PCBA sample order that helped us take the first step. Here’s how it happened—and what we learned along the way.

We became a Decathlon supplier by providing a fast, full-service PCB assembly (PCBA) sample for a smart fitness device prototype. Our low-MOQ, turnkey service and RoHS-compliant manufacturing helped us meet their technical standards and timeline. This first sample paved the way for long-term partnership discussions.

Here’s how we stood out to one of the world’s biggest sporting goods brands—and what other EMS companies can learn from our journey.

How do I become a supplier to Decathlon?

Becoming a supplier for Decathlon often begins with small steps. In our case, it started with an online inquiry. Their procurement team found us through Google while searching for a fast sample PCBA manufacturer in China. Within 24 hours, we responded with a tailored quotation and confirmed our technical capabilities. The initial project—a custom PCB for smart fitness devices—required not only fast delivery but also full compliance with EU RoHS standards.

Most new suppliers start with sample validation. Decathlon assesses fit based on product quality, communication speed, and the supplier’s ability to scale, as outlined in their manufacturing responsibilities.

Most new suppliers start with sample validation. Decathlon assesses fit based on product quality, communication speed, and the supplier’s ability to scale. A reliable PCB supplier for international brands must demonstrate all three—especially during the prototyping phase.

What does Decathlon look for in a supplier?

While price matters, it’s only one piece of the puzzle. During early discussions, it became clear Decathlon valued:

-

Responsiveness – Their team appreciated our detailed technical replies within 12–24 hours.

-

Flexibility – We offered PCB assembly services for sports equipment without a minimum order quantity.

-

Compliance – Our RoHS-compliant PCB assembly from China helped satisfy regulatory requirements.

-

Past Experience – We highlighted prior projects as an EMS provider with global client experience.

Rather than selling ourselves aggressively, we focused on clear communication, transparency about capabilities, and listening to their needs.

In addition to competitive pricing and sustainability, Decathlon uses a structured process for onboarding suppliers, as explained in their Supply Chain Disclosure.

Why was our PCBA sample order a turning point?

The turning point came in June 2025 when Decathlon requested a PCBA sample order for one of their new smart fitness prototypes. The project was challenging—small batch, custom BOM, lead-free soldering, and tight delivery expectations.

Thanks to our turnkey PCB manufacturer with no MOQ model, we handled:

-

PCB fabrication

-

Component sourcing

-

SMT + through-hole assembly

-

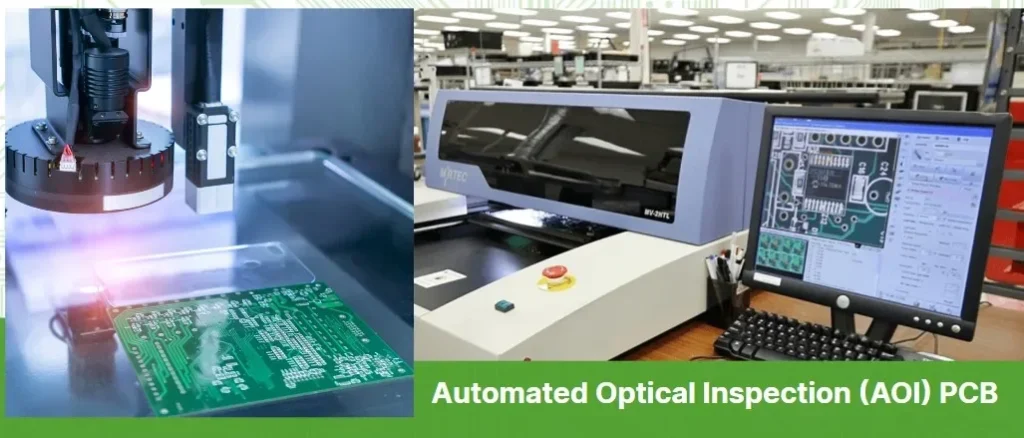

In-circuit and functional testing

Despite its small scale, we treated it with full production seriousness. By July 2025, the samples were shipped from our Shenzhen facility, meeting both function and timeline expectations. Our internal sales engineer, Emily Zhang, played a key role in coordinating between procurement and production.

Turnkey solutions help brands prototype faster with less friction, as explained in our post on why turnkey PCB assembly services matter.

What are PCB sample orders used for?

Sample orders are common in electronics manufacturing, especially when working with large buyers. They allow companies like Decathlon to:

-

Test functionality in real-world environments

-

Validate DFM (Design for Manufacturing) feedback

-

Assess communication quality and delivery reliability

A successful sample often leads to deeper engagement. For OEM electronics manufacturers, it’s a critical first touchpoint.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Why are small batch PCBA services important for prototyping?

Innovation in smart devices moves fast. Brands can’t afford to wait for large MOQs or slow processes. That’s why small batch PCB suppliers in China with no MOQ options are gaining traction.

Our model is built for this stage:

-

Quick quoting (within 24 hours)

-

Component sourcing support

-

End-to-end manufacturing

-

DFM feedback when needed

This flexibility is essential for R&D teams iterating on design—especially for hardware like sports electronics or IoT fitness gear.

Industry pain points in PCBA—and how we solve them

The PCBA industry faces a few common issues, especially in prototype phases:

| Pain Point | Our Approach |

|---|---|

| Delayed communication | Fast engineer-to-engineer feedback |

| Component shortages | Broad sourcing network with real-time inventory |

| Quality inconsistencies | In-house QC + partner audits |

| MOQ inflexibility | Open to samples & small batches |

| Certification complexity | Guidance on RoHS, CE, and functional tests |

Our goal isn’t to outshine larger EMS firms. Instead, we aim to fill the gap between prototyping and scale, acting as a modest but reliable electronics manufacturing partner.

How to get Decathlon to notice your EMS company

We didn’t run ads or send cold emails. Decathlon found us through organic search—thanks to our site’s visibility for terms like:

-

Custom PCB for smart fitness devices

-

PCBA supplier trusted by international brands

-

Turnkey PCB assembly with no MOQ

Here are a few strategies that helped:

-

Clear Website Positioning – We featured capabilities like turnkey service, sample support, and certifications on the homepage.

-

Technical Blog Content – Articles on lead-free soldering, fast PCB quotes, and PCB prototyping tips built credibility.

-

Visible Certifications – We highlighted RoHS, CE familiarity, and process control with real photos.

Sustainable and RoHS-compliant PCB assembly from China

Sustainability and compliance were non-negotiable. Decathlon requested RoHS-compliant assemblies from the start. Our factory followed:

-

Lead-free soldering processes

-

RoHS component sourcing

-

E-waste reduction practices

By positioning ourselves as a sustainable electronics manufacturing partner, we aligned with their global ESG goals—without making it a marketing gimmick.

RoHS compliance isn’t just a checkbox—it directly impacts long-term reliability and market access, as explored in our guide on RoHS-compliant solder choices.

FAQs

1. Do you offer PCB prototyping for smart devices with custom requirements?

Yes, we provide PCB prototyping tailored to smart devices, including sensor integration, Bluetooth modules, and compact form factors. Whether you're refining a wearable or testing a new fitness tracker, our engineering team supports you from schematic review to sample delivery. We're a custom PCB supplier for smart fitness devices with full DFM support and no MOQ.

2. Can I get a fast PCB quote online with BOM analysis?

Absolutely. Our fast PCB quote online system allows you to upload your BOM and Gerber files directly. You'll receive a detailed quote—covering materials, assembly, and lead time—within 24 hours. This is ideal for engineers needing a quick estimate for small batch PCB assembly in China without delays or hidden fees.

3. How do you ensure quality control for small PCBA runs?

For every PCBA sample order, we follow strict IPC-A-610 standards and perform full visual, in-circuit, and functional testing. Our team verifies each board individually to maintain precision even in low-volume runs. This approach makes us a reliable PCBA supplier trusted by international brands who expect consistent quality from the first piece.

4. Are your electronics manufacturing services RoHS-compliant and eco-friendly?

Yes, we offer RoHS-compliant PCB assembly from China, using lead-free soldering and EU-compliant materials. As a sustainable electronics manufacturing partner, we also minimize e-waste and follow eco-friendly sourcing policies. This helps our clients meet both regulatory and corporate sustainability goals—without compromising quality or delivery times.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

What we learned—and what you can do too

We didn’t expect a big order. What mattered was showing professionalism on a small one.

-

Be fast and clear – even on weekends.

-

Don’t oversell—deliver.

-

Optimize your site for the right keywords.

-

Make it easy to say “yes” to a sample.

This experience didn’t make us “big.” But it made us better—and taught us what it takes to work with serious, global brands.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!