Quick Leads

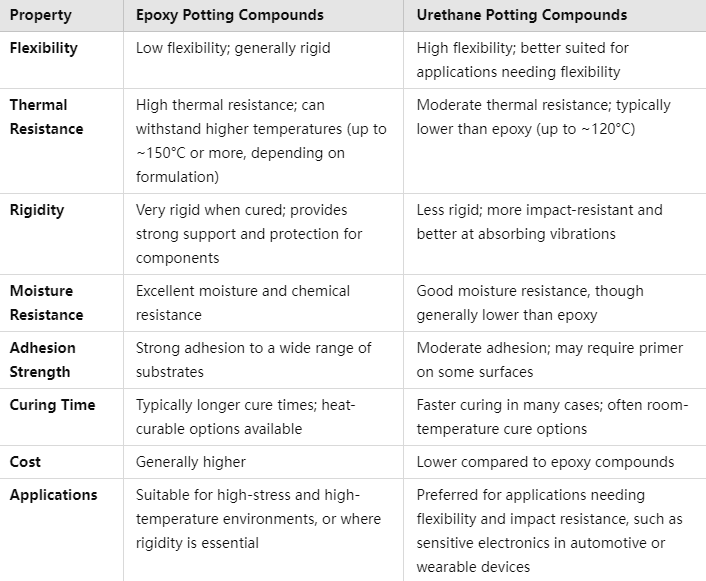

What Are the Differences Between Epoxy and Urethane Potting Compounds?

In this guide, we’re going to take a look at the key differences between epoxy and urethane potting compounds. We’ll focus on their mechanical properties, thermal management, chemical resistance, and best-use applications.

Whether you’re deciding which compound is best for high-temperature electronics or vibration-heavy environments, understanding these differences is crucial for making informed decisions.

Epoxy and urethane potting compounds differ primarily in mechanical properties, temperature tolerance, and flexibility.Epoxy materials are known for their rigidity, excellent thermal and chemical resistance, and strength, making them ideal for high-temperature environments. Conversely, urethane materials offer excellent flexibility, elongation, and abrasion resistance, making them better suited for applications requiring shock absorption and vibration resistance.

Let’s dive into a detailed comparison of their properties, curing processes, cost considerations, and best applications to help you choose the right potting compound for your electronics.

1. Mechanical Properties: Rigidity vs. Flexibility

When you compare epoxy vs. urethane potting compounds, one of the biggest differences is their mechanical properties. Epoxy compounds are great because they have superior mechanical strength and rigidity. This makes them perfect for high-stress applications like aerospace electronics and industrial equipment where durability is key.

Urethane potting compounds, on the other hand, are known for their flexibility. They can stretch and resist abrasion, which makes urethane the best choice for applications like automotive sensors where there’s a lot of movement, vibration, or impact.

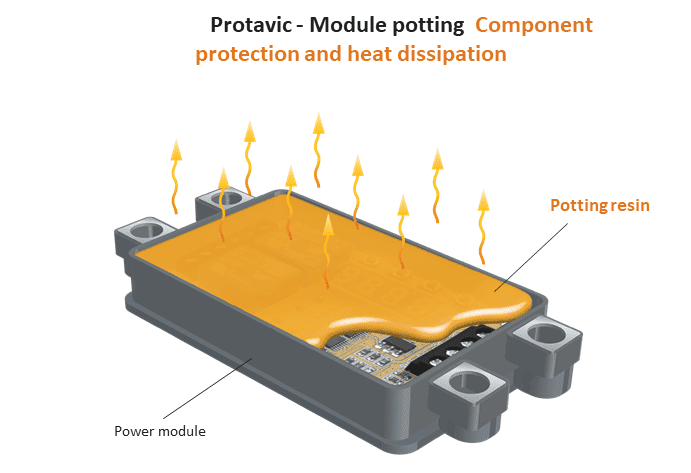

2. Thermal Management: Heat Dissipation and Performance

Thermal management is super important in electronics, especially in high-power or extreme temperature environments. Epoxy compounds are great for heat dissipation and have high thermal resistance, which is why they are used in high-temperature applications like industrial electronics and aerospace components.

Urethane compounds, on the other hand, have decent thermal resistance but are really good at being flexible and tough. Urethanes are better for electronics that don’t need a lot of heat management, so they are more applicable in automotive or consumer devices that get a moderate amount of heat.

3. Chemical Resistance: Handling Environmental Exposure

In terms of chemical resistance, epoxy compounds are the best at protecting against harsh chemicals, solvents, and moisture. This makes them the best choice for applications in corrosive environments, like industrial settings or chemical processing plants.

Urethane potting compounds, while they have good chemical resistance, are usually used where impact resistance and flexibility are more important than long-term exposure to harsh chemicals. Urethane is often used in outdoor environments where physical stress and environmental exposure, like UV radiation, are the main concerns.

4. Cure Time and Application Process

Urethanes usually cure faster and at lower temperatures, which is good for fast-paced production environments where you need to get things done quickly. They are generally easier to work with in applications that need fast processing, so they are good for consumer electronics or automotive industries.

Epoxy potting compounds, on the other hand, usually take longer to cure and need higher temperatures. While this might slow down the production process, the result is a stronger, more durable bond, especially in applications that face a lot of stress or environmental conditions.

5. Cost Comparison: Which is More Economical?

When you look at the cost of epoxy versus urethane potting compounds, epoxies are usually more expensive because they are stronger, more resistant to chemicals, and last longer. But in industries like aerospace or industrial electronics, where performance is super important, the higher cost is worth it.

Urethane compounds are cheaper, especially in applications where flexibility and fast processing times are more important than extreme durability. For example, in high-volume automotive manufacturing, urethane’s lower cost and faster curing make it the more economical option.

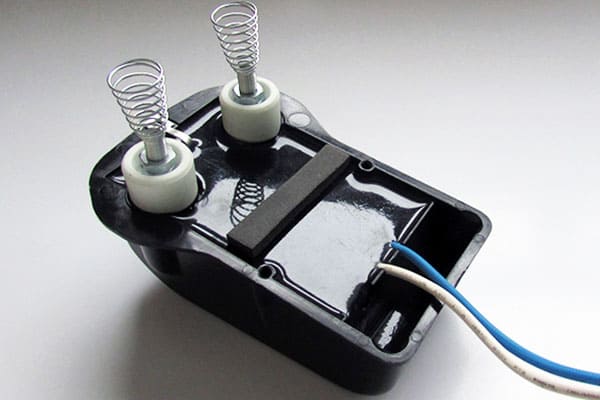

6. Applications: Where Each Compound Excels

Epoxy compounds are the best for high-strength, high-temperature applications. They have great chemical resistance and are rigid. Common use cases include:

- Aerospace electronics

- Industrial machinery

- Automotive components exposed to extreme heat

Urethane compounds, on the other hand, are really good at being flexible and resisting abrasion. They are great for:

- Automotive sensors

- Wearable electronics

- Consumer devices requiring shock absorption

7. Environmental Impact: Sustainability Concerns

When it comes to environmental impact, urethane compounds are often seen as more sustainable. They cure faster, which means less energy is used, and they tend to release fewer volatile compounds during processing. This makes urethane a good choice for manufacturers who want to reduce their environmental footprint.

While epoxies are more durable, their long-lasting chemical properties can make them hard to dispose of. But because they last a long time, you might not need to replace them as often, which could make up for the environmental cost in the long run.

For more information, visit below:

For more insights on differences between epoxy and urethane potting compounds, check out: potting-and-encapsulation-in-the-electronics-industry

Frequently Asked Questions (FAQ)

Epoxy is better for high-temperature environments because it has better thermal resistance. Urethane is better for applications where you need flexibility and shock absorption.

Yes, epoxy is good for outdoor environments because it resists chemicals, especially in harsh conditions where there’s moisture and solvents.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

When you’re deciding between epoxy and urethane potting compounds, it really depends on what you need for your application. Epoxy compounds are the best for strength, chemical resistance, and thermal durability, so they are great for high-stress environments.

Urethane compounds, on the other hand, are really good at being flexible, curing fast, and resisting vibration, so they are perfect for applications where you need shock absorption and fast processing.

Need help choosing the right potting compound? Contact us today for expert advice and customized solutions that fit your specific electronics projects.

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!