Quick Leads

Electronic Manufacturing Process: 10 Essential Steps for Quality, Efficiency, and Reliability

Introduction

Today’s fast-paced electronics industry must balance quality, cost, and efficiency. Global supply chain disruptions and a need for speed make this tough.At Unit Circuits, we get it. We have a 10-step process for electronic manufacturing. It ensures quality, efficiency, and reliability. We help clients deliver better products, on time and on budget. We do this by mastering each production phase.

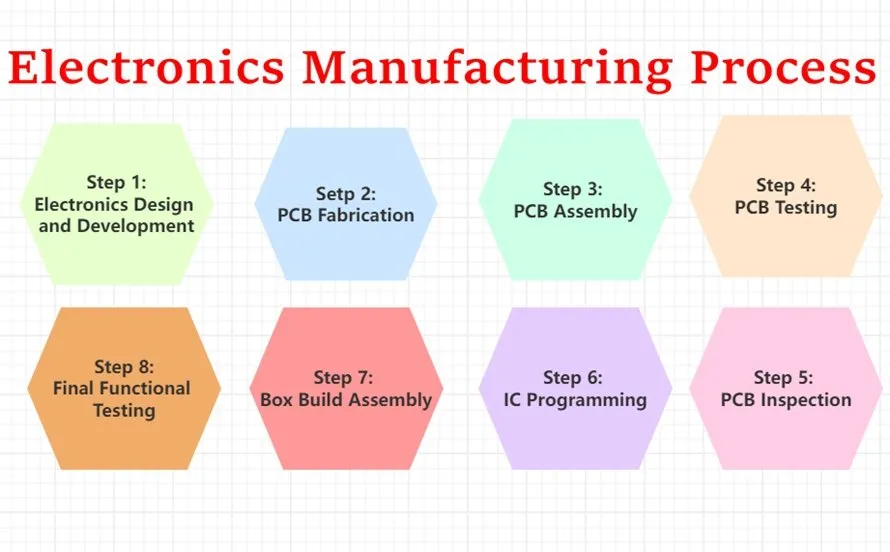

Quick Overview of the 10 Steps

Here’s a high-level look at each step and its purpose:

| Step | Description |

|---|---|

| Design & Prototyping | Define product specifications and create prototypes. |

| Component Sourcing | Secure high-quality components from reliable suppliers. |

| PCB Manufacturing | Fabricate printed circuit boards with precision. |

| PCB Assembly | Mount components onto the PCB using advanced techniques. |

| Solder Paste Printing | Apply solder paste accurately for strong adhesion. |

| Component Placement | Position components precisely using automated machines. |

| Reflow Soldering | Secure components by melting and solidifying solder. |

| Inspection & Testing | Ensure quality through AOI, X-Ray, and functional tests. |

| Final Assembly | Integrate additional components and enclosures. |

| Quality Control & Shipping | Perform final checks and package products securely. |

Detailed Step-by-Step Breakdown

Step 1: Design & Prototyping in Electronics Manufacturing

-

Industry Insight: At Unit Circuits, we implement Design for Manufacturability (DFM) practices. This collaborative approach identifies potential manufacturability challenges early, reducing costly changes later.

-

Client Benefit: DFM not only optimizes your design, it also helps you save money and avoid delays caused by design issues.

-

Best Practice: Work with your EMS provider early on. Agree on specs and address any manufacturability concerns.

Step 2: Component Sourcing in Electronics Manufacturing

- Key Considerations: Reliable components are critical to maintaining quality. Current supply chain challenges make sourcing high-quality parts essential to avoid delays.

- Industry Insight: At Unit Circuits, we use a network of suppliers we trust and we use strategic sourcing. This minimizes disruptions and ensures the timely delivery of quality components.

- Best Practice: Supply Chain Flexibility—Work with an EMS provider that buys from multiple suppliers. They stock critical components. This helps you avoid supply chain disruptions.

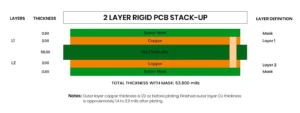

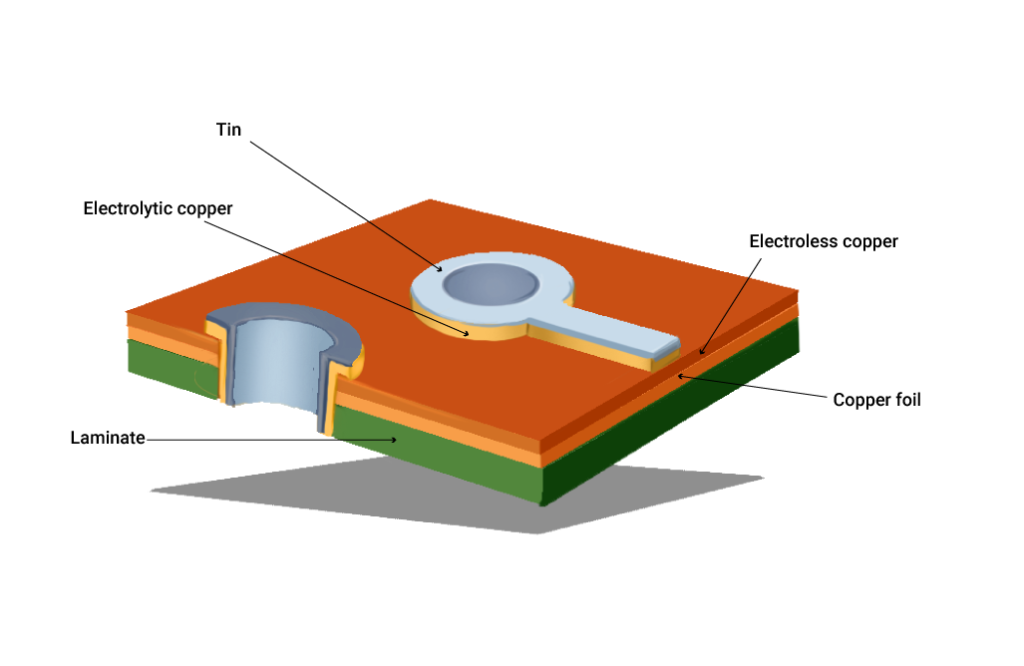

Step 3: PCB Manufacturing Process

- Process Overview: When you make a PCB, you pick your materials, build your layers, and make sure your traces are laid out correctly. Quality inspections focus on identifying defects like open circuits, which could disrupt assembly.

- Client Benefit: A thorough inspection of your PCB from the start helps you avoid defects during assembly. These defects can delay production and hurt product performance.

- Best Practice: Material Selection—Choose an EMS provider that values PCB inspections and quality parts. This will ensure long-term reliability.

Step 4: PCB Assembly (PCBA) in Electronics Manufacturing

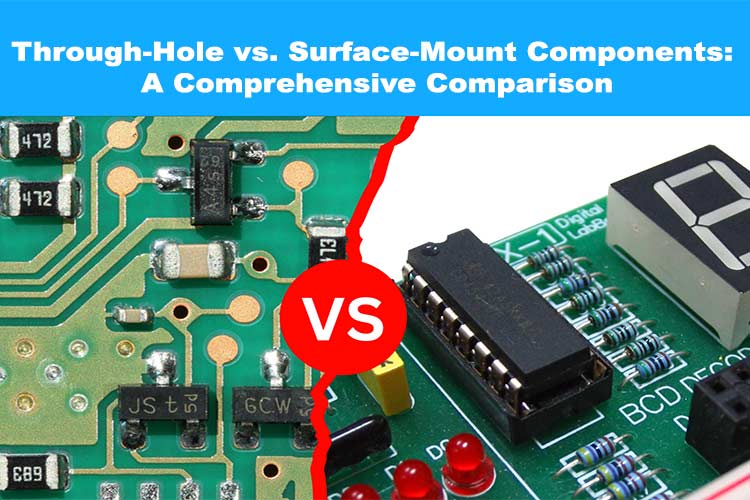

- SMT vs. THT: **Surface Mount Technology (SMT)** is best for compact, high-density designs. **Through-Hole Technology (THT)** is better for components that will endure mechanical stress.

- Industry Insight: Our advanced SMT and THT skills ensure precision. They suit high-density boards and robust, stress-resistant connections.

- Best Practice: Assess Assembly Requirements—Ensure your EMS provider can do SMT and THT. They must meet your specific application needs.

Step 5: Solder Paste Printing Process

- Accuracy in Application: If you don’t apply solder paste correctly, you’ll end up with solder bridges and incomplete connections.

- Industry Insight: Unit Circuits calibrate our stencils and keep our paste consistent. This gives us good adhesion and solid connections.

- Best Practice: **Stencil Calibration**—Calibrate your stencils. Check your paste quality. This will avoid problems and ensure your connections last.

Step 6: Automated Component Placement in Electronics Manufacturing

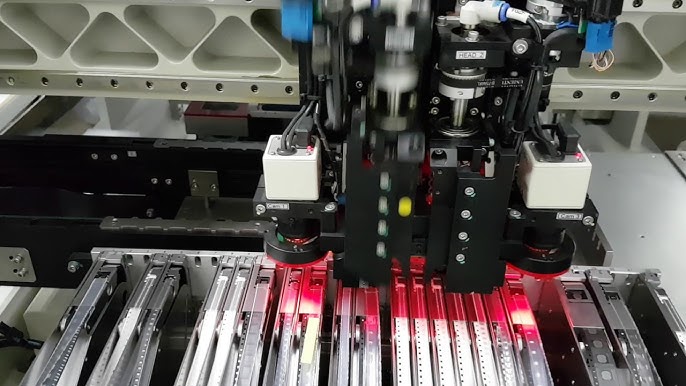

- Automated Precision: Automated pick-and-place machines quickly and accurately put components on boards. You can make a lot of them, and they’ll all be good.

- Client Benefit: Automated placement means no human error and the same thing happens every time, even if you’re doing a lot of it.

- Best Practice: Choose an EMS provider with high-speed, calibrated pick-and-place equipment. It will ensure your components are placed correctly.

Step 7: Reflow Soldering in PCB Assembly

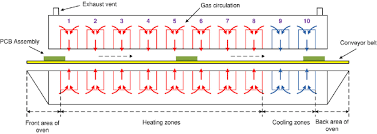

- Custom Temperature Profiles: We control the temperature in reflow soldering so we don’t damage the parts but still get good solder joints.

- Industry Insight: We make custom reflow temperature profiles for different components. This ensures good solder joints and avoids damaging the parts.

- Best Practice: Temperature Profiling—Ensure your EMS provider uses good temperature profiles. This protects your sensitive components and makes good solder joints.

Step 8: Inspection and Testing for Quality Assurance

- Advanced Inspection Techniques: AOI and X-Ray Inspection find defects in high-density boards.

- Functional Testing: We test every board to make sure it works before we ship it to you.

- Best Practice: Dual Inspection Methods—AOI for surface issues and X-ray for internal inspection. This dual approach provides comprehensive quality assurance, catching a broader range of defects.

Step 9: Final Assembly in Electronics Manufacturing

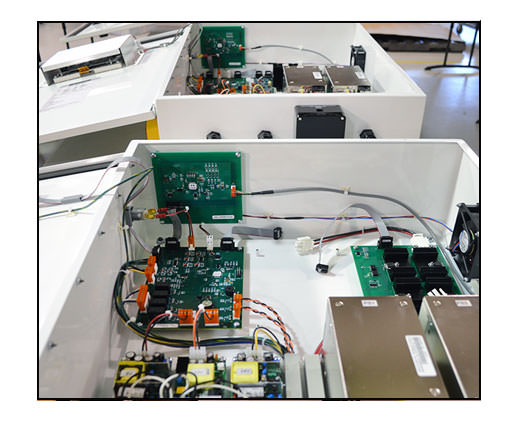

- Process Overview: Final assembly is adding parts or enclosures to complete the product.

- Industry Insight: We can customize the assembly steps to meet your needs, like putting it in a box that you want.

- Best Practice: Choose an EMS provider with experience in custom assembly for unique integration needs.

Step 10: Quality Control & Shipping in Electronics Manufacturing

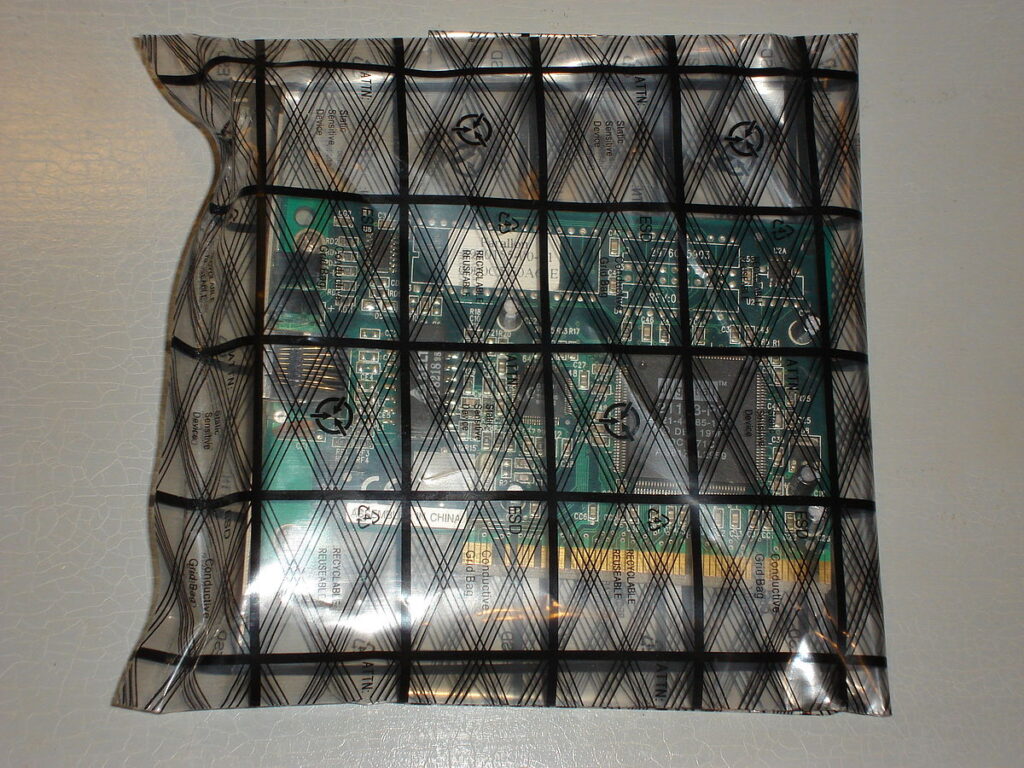

- Protective Packaging: We check everything. It must be in anti-static, labeled packaging to avoid damage in transit.

- Industry Insight: Specialized packaging protects sensitive electronics from electrostatic discharge, ensuring safe delivery.

- Best Practice: Protective Packaging—Choose an EMS provider. They must package and document your shipments securely. This ensures they arrive safely and reliably.

Conclusion

Each of these ten steps is critical to making sure you get a high-quality, reliable electronic product.Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverCall to Action

At Unit Circuits, we don’t just manufacture products—we work with our clients at every stage to ensure the process aligns with their business goals. We will help you bring reliable products to market faster and cheaper. We are committed to this from initial design to final quality checks and secure packaging.Contact us today. Learn how our expertise can improve your production.

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select the right transformer for SMPS, IoT, or relay control. Start designing smarter today.

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and delivery—and how turnkey EMS solutions protect your product and bottom line.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!