Quick Leads-PCBA

Need a PCB Fast, Without the Usual Hassles?

Need a fast PCB prototype with no minimums and reliable testing? If delays, hidden costs, and inconsistent quality are stressing you out, you’re not alone. But there’s a solution: quick turn PCB services with global shipping, no MOQ, and guaranteed tested PCB prototypes.

What’s the Quickest Way to Get a PCB Prototype?

A fast PCB prototype service typically delivers within 24–72 hours, offering global delivery, no minimum order quantity (MOQ), and full testing. These services are designed for startups, engineers, and small-volume needs where speed and quality matter. By combining in-house manufacturing, DFM checks, and automated testing, manufacturers achieve rapid PCB prototyping without compromising reliability.

Why Is PCB Turnaround Still a Problem in 2025?

Even in 2025, engineers still face frustrating delays during prototyping. Here’s why:

-

Outdated quoting systems: No instant feedback, no BOM cross-checking.

-

Lack of in-house assembly: Most factories outsource, creating longer lead times.

-

MOQ limitations: Small runs are often rejected or overpriced.

-

No pre-testing: Many services ship untested boards, risking rework.

That’s where rapid PCB prototyping services that offer quick PCB fabrication with full testing change the game.

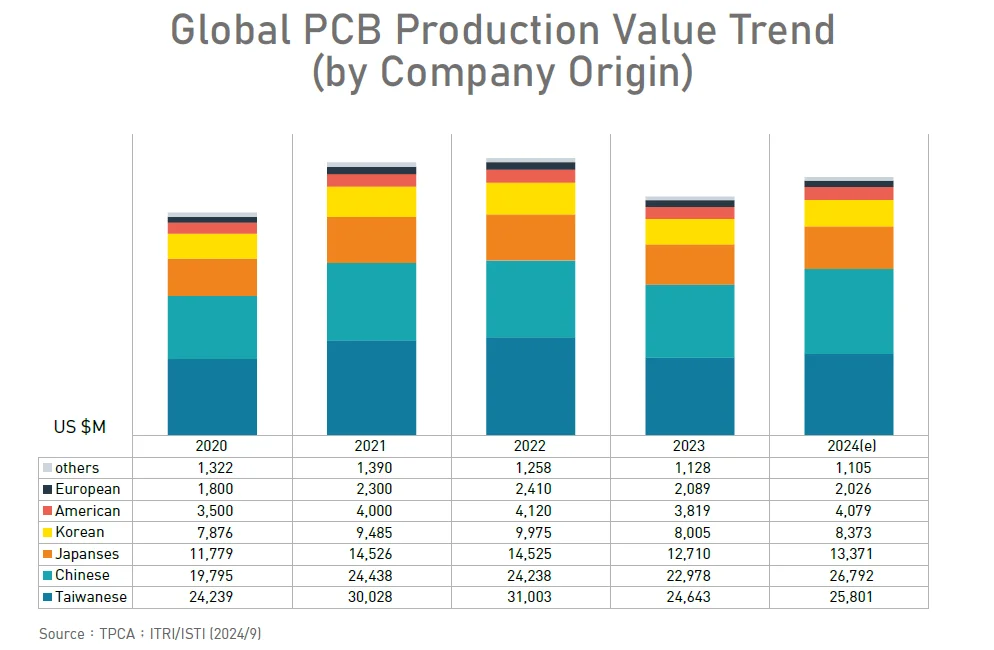

Fast PCB Manufacturer in China vs Overseas

| Feature | Fast PCB Manufacturer (China) | US-Based Service | EU-Based Service |

|---|---|---|---|

| Typical Turnaround | 24–72 hours | 3–7 days | 5–10 days |

| Minimum Order Requirement (MOQ) | No MOQ | 5–10 pcs | Often MOQ 10+ |

| Testing Included? | Yes (AOI, FCT) | Often optional | Varies |

| Online Quote Available? | Yes – real-time | Sometimes (via email) | Rare |

| Average Cost for 2-layer, 10pcs | $35–$50 | $90–$150 | $120+ |

This is why more startups, engineers, and hardware devs are turning to reliable PCB suppliers in China who offer global PCB shipping and turnkey PCB manufacturing.

When evaluating overseas suppliers, it’s not just about cost or speed. Engineers should also consider file compatibility, quoting accuracy, and factory transparency. This 2025 guide outlines the most important criteria for picking a low-cost PCB prototype supplier in China with both reliability and fast turnaround in mind.

What Exactly is a PCB Prototype?

A PCB prototype is the first fully functional version of a printed circuit board. It’s built to test a concept before full-scale production. Unlike final runs, it’s focused on design validation, component placement, and signal testing.

-

Small batch PCB production is ideal here—cost-effective and fast.

-

Engineers use prototypes to test edge cases and tweak trace layouts.

-

Cost-effective PCB prototypes keep R&D cycles moving quickly.

💡 This step is non-negotiable if you want to avoid mistakes downstream.

These boards help reduce time-to-market dramatically. (See IJERT’s take on quick turn PCB advantages).

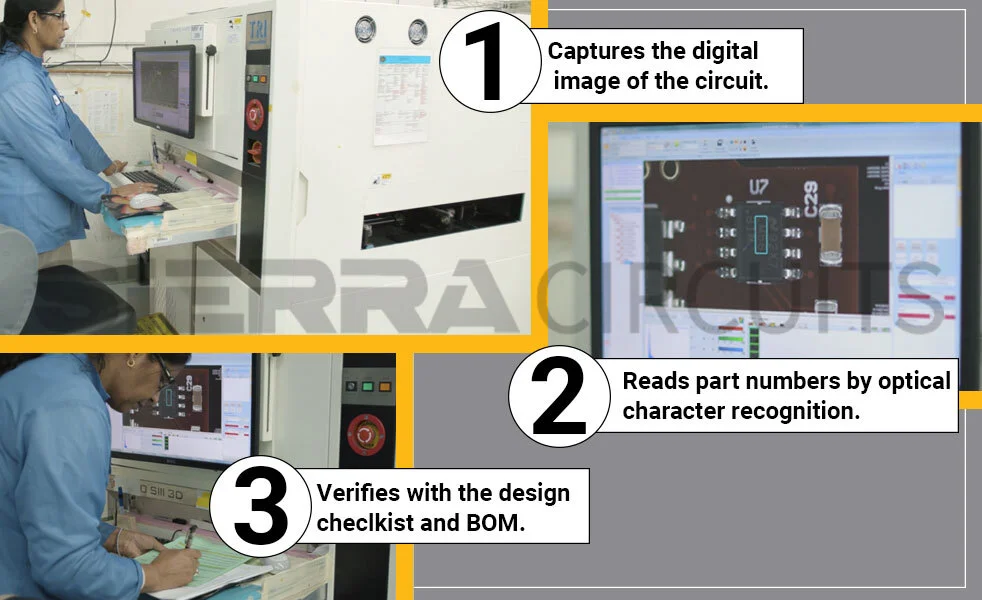

How Quick Turn PCB Assembly with Testing Works

Many engineers wonder what “quick turn PCB with testing” really means. Here’s the process:

-

You upload your files (Gerber, BOM, pick & place).

-

You get a same-day PCB quote—with DFM (Design for Manufacturability) feedback built-in.

-

The boards are produced, often in 24–48 hours, thanks to expedited PCB services.

-

Final products are tested, often via:

-

AOI (Automated Optical Inspection)

-

ICT (In-Circuit Test)

-

FCT (Functional Circuit Test)

-

Tested PCB prototypes eliminate nasty surprises like bad vias or reversed polarities—especially crucial for quick turn PCB assembly.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

No MOQ PCB Prototyping: Big Deal for Startups

MOQ (Minimum Order Quantity) sounds like a business term. But in prototyping? It’s a roadblock.

For early-stage hardware teams:

-

You want 1–10 boards, not 1000.

-

You need to test fast, pivot even faster.

-

Your investors won’t pay for volume unless it’s proven.

That’s why PCB prototyping services for startups are moving toward no minimum PCB order.

Even better, low-cost PCB prototyping means you don’t burn your runway on early experiments.

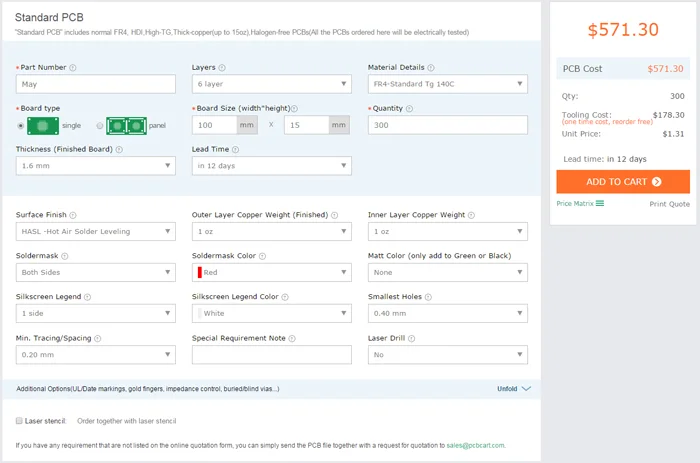

What to Look For in Rapid PCB Prototyping Services

Not all services are created equal. Here’s what to prioritize:

✅ Speed – Look for same-day or 24-hour fabrication.

✅ Testing – AOI, ICT, FCT options must be included.

✅ Quote Transparency – A real-time PCB cost calculator is essential.

✅ Support for Low Volume – Ensure true low volume PCB prototyping with fast delivery.

✅ Instant Feedback – Built-in DFM & DFA analysis on upload.

With a solid turnkey PCB manufacturing setup, all of this can happen in one place.

How Long Does PCB Prototyping Take Based on Specs?

| PCB Complexity | Layers | Assembly Type | Typical Turnaround Time |

|---|---|---|---|

| Basic Prototype | 2 | No Assembly | 24–48 hours |

| Assembled Prototype | 2–4 | SMT | 3–5 days |

| HDI/Multilayer | 6–8 | Mixed SMT/THT | 7–10 days |

| Flex PCB | Varies | Custom | 7–12 days |

How to Choose the Right Quick PCB Fabrication Service

There are dozens of options online. Here’s how to filter them:

-

Does the platform offer a same-day PCB quote?

-

Can it process BOMs with part alternatives?

-

Are expedited PCB services integrated with in-house assembly?

-

Does the provider disclose their PCB stackup options?

Using quick PCB fabrication services that offer these features saves you time, cost, and debugging headaches.

Solving Industry Pain Points: What Engineers Actually Face

Let’s get honest—most delays aren’t in fabrication. They’re in:

🚫 BOM part sourcing confusion

🚫 Incomplete quotes

🚫 Poor soldering QC

🚫 Multiple handovers between vendors

Here’s How We Solved These:

✅ In-house sourcing + DFM + DFT + AOI

✅ PCB parts cross-matched automatically

✅ Instant PCB material cost comparison

✅ Functional Testing (FCT) before shipping

✅ One account = fab + assembly + testing

The result? Fewer failed boards, lower stress, faster product launches.

From Quote to Delivery: Get a Fast PCB Prototype Quote Online

Most sites still want you to wait 24 hours for a manual quote. Ours? You get:

-

Same-day quote

-

Layer, finish, and stackup options

-

Real-time pricing

-

DFM suggestions right after upload

This supports fast PCB prototype quote online workflows and keeps teams moving fast.

FAQs

1. Can I get a fast PCB prototype even if my design files are incomplete?

Yes, some manufacturers now offer rapid PCB prototyping services with engineering support. If you’re missing a full BOM or unsure about your PCB stackup, providers with a turnkey PCB manufacturing system can guide you through revisions. This is especially helpful for startups or first-time hardware teams. Look for services that offer DFM review and component suggestions—so you don’t waste time going back and forth.

2. What should I do if my PCB prototype needs specific material or finish options?

You don’t need to compromise. Many fast PCB prototype manufacturers in China support a range of materials like Rogers, FR4, or aluminum PCBs. You can select custom stackups, copper weights, or ENIG finishes—all from a same-day PCB quote platform. These flexible material options help ensure both electrical performance and long-term durability, even on low volume PCB prototyping with fast delivery.

3. Is fast PCB prototyping more expensive than traditional production?

Not necessarily. While quick PCB fabrication does carry a rush fee, the overall cost can be lower due to reduced delays, fewer redesigns, and faster go-to-market. With no MOQ and online pricing tools like a PCB cost calculator, you can compare options in real time. It’s a cost-effective PCB prototype strategy, especially for agile teams who value speed and iteration.

Fast turnaround doesn't always mean a higher price. In fact, by reducing idle time, speeding iteration, and optimizing your BOM, you might even spend less overall. Here’s how cost factors stack up across PCB assembly projects—and where quick turn services offer unexpected savings.

4. Can I trust the quality of fast PCBs for final testing or field trials?

Absolutely—if the boards are tested PCB prototypes. Trusted suppliers perform functional circuit tests (FCT), AOI, and flying probe testing before shipping. These steps make your prototypes reliable enough for pre-certification, client demos, or pilot runs. Choosing a quick turn PCB assembly with testing ensures your project doesn’t stall due to defects or missed connections during field validation.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary

Getting your PCB prototype shouldn’t feel like a gamble. With fast delivery, no MOQ, and full testing, our approach is made for engineers who don’t have time to waste. Explore our instant quote tool and experience low volume PCB prototyping with fast delivery—without the headaches.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!