Quick Leads

The world of wearable technology is evolving rapidly. What was once an area reserved for bulky devices with limited functionality is now a thriving industry filled with high-tech gadgets that are smaller, smarter, and more integrated into our daily lives. Behind the scenes, flexible PCBs (Printed Circuit Boards) are driving this revolution. These innovative boards offer the flexibility, durability, and efficiency required to meet the growing demand for wearable electronics.

By 2025, wearable tech is expected to evolve to a level where flexible PCBs will be indispensable in areas like healthcare, fitness monitoring, smart clothing, and automotive electronics. The demand for PCB assembly services that specialize in flexible designs will skyrocket as companies push the boundaries of what’s possible with wearables.

What Are Flexible PCBs and Why Are They Essential for Wearable Devices?

Flexible PCBs are circuit boards made from materials that allow them to bend, twist, and fold while still maintaining functionality. Unlike traditional rigid PCBs, flexible PCBs are crucial in compact, lightweight wearable devices that must conform to the user’s body or fit into spaces where traditional PCBs wouldn’t work.

Flexible PCBs have become crucial for wearable devices such as fitness trackers and smartwatches: Elite Wearable PCB Devices Utilizing Flex PCBs

Why Flexible PCBs Are a Game Changer for Wearables:

- Compact and Lightweight: Flexible PCBs reduce the weight and size of devices, making them ideal for wearables like smartwatches, fitness trackers, and medical monitoring devices.

- Form Factor Flexibility: These boards can be shaped to fit the contours of your body, allowing for better integration in products like smart clothing or wearable sensors.

- Durability: Flexible PCBs can withstand constant bending and flexing, making them more reliable over time compared to rigid PCBs.

The Future of Wearable Technology: What Role Will Flexible PCBs Play?

By 2025, we expect wearable technology to become more integrated into daily life, with smart clothing, medical devices, and automotive wearables becoming commonplace. Flexible PCBs will be at the heart of these devices, making them more functional and comfortable for users.

Flexible PCBs’ ability to conform to curved surfaces and dynamic movements offers a new frontier in wearable design: Bending The Rules: Flexible PCBs in Wearable Tech

Some examples of future wearables that will rely on flexible PCBs:

- Wearable Health Devices: Flexible PCBs allow for continuous health monitoring, from blood pressure to glucose levels, all integrated seamlessly into smart patches or sensor-embedded clothing.

- Smart Textiles: Flexible PCBs will enable clothing items to monitor everything from heart rate to muscle activity, offering athletes and healthcare professionals real-time data.

- Automotive Applications: Flexible PCBs will be used in smart vehicle systems, from driver health monitoring to automated controls.

What is the Future of the PCB Industry?

The PCB industry is expected to see significant growth as flexible PCBs take center stage. The market is evolving with the rise of IoT, 5G, and the wearable tech revolution.

Key drivers of this growth include:

- Advanced Connectivity: As 5G networks become mainstream, demand for smaller, more efficient electronics increases. Flexible PCBs are critical to enabling the small form factor needed for these devices.

- Sustainability: Flexible PCBs made from eco-friendly materials will play a crucial role in reducing waste in electronics manufacturing.

- Miniaturization: As technology continues to shrink, flexible PCBs will allow manufacturers to fit more components into smaller, more efficient designs.

Rigid-Flex PCBs: Combining Durability and Flexibility for Wearables

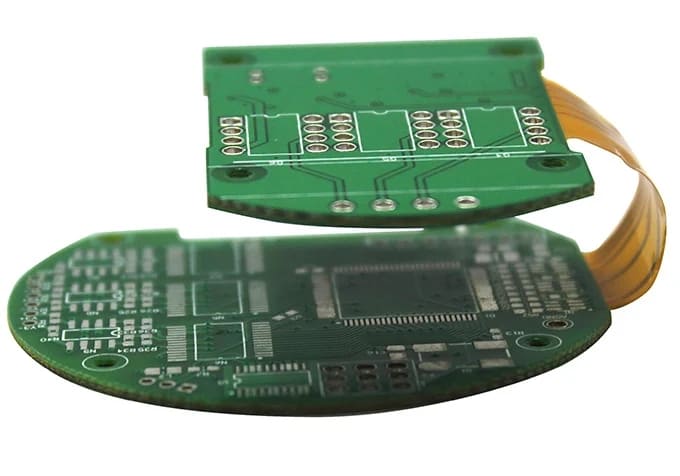

While flexible PCBs are great for a variety of applications, rigid-flex PCBs offer an even more robust solution. These are a hybrid of both rigid and flexible PCBs, offering the durability of rigid boards with the flexibility of flexible ones.

For example:

- Smartwatches: Rigid-flex PCBs are perfect for wearables that need to maintain a rigid structure but still offer some flexibility in certain areas like the wristband.

- Healthcare Devices: Devices like ECG monitors require a mix of rigid and flexible PCBs to ensure both compactness and durability.

The rise of rigid-flex PCBs is driven by their durability and versatility in dynamic environments like wearable tech: The Rise of Flexible and Rigid-Flex PCBs in Wearable Tech

Comparison Chart: Flexible PCBs vs. Rigid PCBs for Wearables

Here’s a quick comparison chart to highlight the differences:

| Feature | Flexible PCBs | Rigid PCBs |

|---|---|---|

| Size | Smaller, more compact | Larger, less space-efficient |

| Flexibility | Bends, twists, and conforms to shapes | Rigid, fixed structure |

| Durability | Higher resistance to bending, wear | Prone to cracking and breaking |

| Heat Management | Better heat dissipation | Limited heat dissipation |

| Use Case | Wearables, medical devices, IoT | Consumer electronics, larger devices |

Challenges in PCB Assembly for Wearables and How to Overcome Them

PCB assembly for wearables presents several challenges:

- Miniaturization: As devices get smaller, placing components on a tiny PCB becomes more difficult. Advanced automated assembly techniques can overcome this challenge.

- Heat Dissipation: Wearables, especially those with sensors and batteries, can overheat. Flexible PCBs made from heat-resistant materials like polyimide help dissipate heat more effectively.

- Precision and Reliability: Wearable tech needs highly accurate, reliable circuits. Partnering with a PCB assembly service that specializes in high-precision manufacturing ensures the product will perform consistently over time.

How to Choose the Right PCB Assembly Service for Your Wearable Tech Needs

When choosing a PCB assembly service, it’s essential to ensure they understand the unique needs of the wearable technology market. Look for:

- Experience with Flexible PCBs: A provider with experience in flexible and rigid-flex PCBs will ensure better functionality and performance for wearables.

- Quality Control: With wearable devices, accuracy and reliability are critical. Make sure the service has robust quality control measures in place.

- Scalability: Your assembly partner should be able to scale production based on demand, especially as the wearable tech market grows.

Flexible circuits are also revolutionizing medical devices, enabling better health monitoring through wearables: How Flex Circuits and Wearable Tech are Changing Medical Devices

FAQs

Flexible PCBs allow for smaller form factors, lighter weight, and better durability in wearables, making them more suitable for compact devices that need to bend or conform to the body.

While flexible PCBs can be more costly upfront, their cost-efficiency over time—due to better durability, higher performance, and reduced need for replacements—often outweighs the initial investment.

Flexible PCBs offer superior heat dissipation and the ability to withstand bending and twisting, ensuring that wearables continue to function even under demanding conditions like sweat or high activity levels.

Yes, flexible PCBs are ideal for both consumer wearables, like fitness trackers, and medical wearables, such as heart rate monitors or diabetes patches, due to their small size, flexibility, and ability to endure harsh environments.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

Flexible PCBs are a game-changer in wearable technology, offering compact, durable, and efficient solutions for devices that need to be both functional and portable. As wearable technology advances by 2025, these innovative PCBs will enable smarter devices that integrate seamlessly into everyday life.

Whether you’re working on health monitors, sensor technology, or smart wearables, flexible PCBs are essential for overcoming challenges like miniaturization, heat dissipation, and durability. If you’re ready to take your wearable tech to the next level, contact us today for tailored PCB assembly solutions.

Have Specific Requirements?

We’re here to help! Whether it’s a custom PCB design, assembly, or sourcing components, feel free to reach out to us directly. Our team is ready to provide tailored solutions for your project. Contact Us Today for more information.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!