PCBA Testing

Comprehensive PCBA testing services including AOI digital inspection, X-Ray, ICT in-circuit testing and FCT functional circuit test stands to ensure PCB assembly quality.

About PCBA functional testing

PCBA functional testing refers to a type of test that involves simulating the operation of the circuit board under actual usage conditions. This test ensures the electrical conductivity of the PCBA circuit board with mounted electronic components and verifies that the board can function normally according to preset schemes based on input and output values. By conducting functional tests on PCBA, manufacturing and quality issues can be avoided, unnecessary repair costs can be reduced, and the product delivered to customers can be ensured to be intact, thus enhancing customer satisfaction. Additionally, PCBA functional testing is an important means of optimizing PCB design, as potential problems and defects can be identified and eliminated during the testing process. This helps to improve and optimize the design of the circuit board, enhancing its reliability and stability, thereby significantly reducing the risk of crashes and failures.

Quality Control

Accurate Testing

Real-Time Tracking

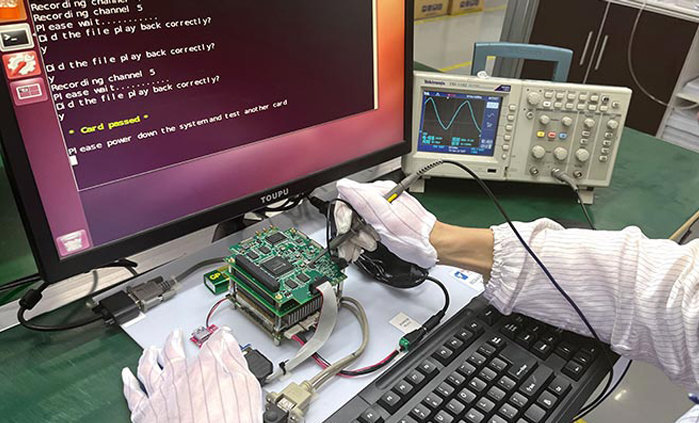

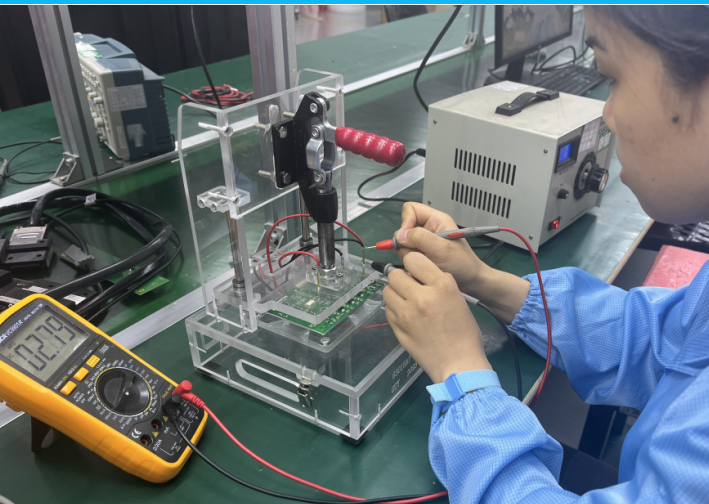

Functional Testing On-site

FAQs about PCB Function Testing

PCB function testing is a critical process that verifies the performance and functionality of your PCBs. It ensures that each board operates correctly under real-world conditions, reducing the risk of failures and improving product reliability.

We perform a range of function tests, including in-circuit testing (ICT), functional circuit testing (FCT), boundary scan testing, and environmental stress screening (ESS), tailored to meet your specific requirements.

Our testing processes are conducted using advanced equipment and methodologies. We follow stringent protocols to ensure high accuracy and repeatability, providing you with reliable results.

Absolutely! We understand that each project is unique, and we can customize our testing procedures to align with your specific performance criteria and testing parameters.

The turnaround time for function testing varies based on the complexity and volume of your order. Typically, you can expect results within a week, but we always strive to meet your deadlines efficiently.

Yes, we provide comprehensive test reports that include detailed data and analysis of each PCB’s performance. These reports help you understand the test results and make informed decisions.

If a board fails the function tests, we perform a thorough analysis to identify the root cause. We then provide you with recommendations for corrective actions and can assist in making the necessary adjustments.

By using our function testing services, you ensure that your PCBs meet the highest quality standards, reducing the risk of field failures and returns. This leads to higher customer satisfaction and lower overall costs for your projects.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0