Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Why “Cheap” PCB Assembly Can Cost You More Than You Think

Cheap PCB assembly seems like a win for the budget — until delays, defects, and rework wipe out all your savings. In this article, we break down the true cost of low-cost PCB manufacturing and what electrical engineers, hardware startups, and sourcing managers need to know before choosing a supplier.

The hidden cost of cheap PCB assembly lies in poor quality control, missing testing services, unstable lead times, and weak communication. These issues often result in rework, delays, and budget overruns — wiping out any initial savings. Engineers should evaluate suppliers based on testing capabilities, BOM management, SMT/THT quality, and support — not just price.

If you’ve ever received a faulty board or scrambled to meet a deadline due to supplier issues, this guide will help you avoid it next time.

What Are the Hidden Costs in PCB Manufacturing?

Low-cost quotes usually skip over hidden charges like:

-

Stencil fees and tooling costs

-

Component substitutions or upgrades made without approval

-

Redesign fees for DFM/DFA feedback

-

Rework costs due to poor assembly or testing

-

Shipping premiums for urgent deliveries

These add-on costs can easily make your “affordable” PCB assembly service more expensive than a premium turnkey provider.

And if there’s a need for scrapping an entire batch? That’s hundreds or thousands lost. Avoiding these costs starts with choosing a manufacturer that’s transparent and detail-oriented from the start.

Why Cheap ≠ Cost-Saving in PCB Assembly

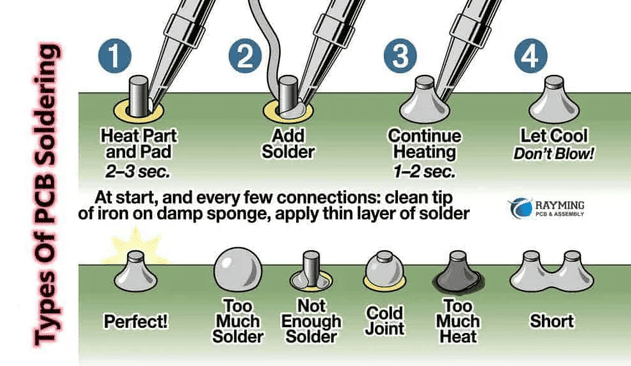

Many engineers equate low price with low risk — especially in early prototypes. But the reality is, cost-saving rarely comes from cutting corners in quality. Many low-cost PCB services cut corners on soldering, placement accuracy, and inspection. Here are the top 8 PCB assembly problems engineers often face — and how to prevent them in your next build.

Here’s what we commonly see with ultra-cheap providers:

-

Soldering issues: cold joints, bridging, poor wetting

-

Component errors: missing, misaligned, or swapped parts

-

Lack of QA: no AOI/X-ray inspection, minimal operator training

All of these lead to rework, downtime, or worse — field failures.Common design and assembly errors—such as component misalignment or poor reflow profiles—are well-documented in this guide by MacroFab.

That’s why our approach at Unit Circuits focuses on design-for-assembly consultation, real-time communication, and full PCB quality control, no matter the batch size.

SMT and THT Assembly Services in China — What’s the Real Difference in Quality?

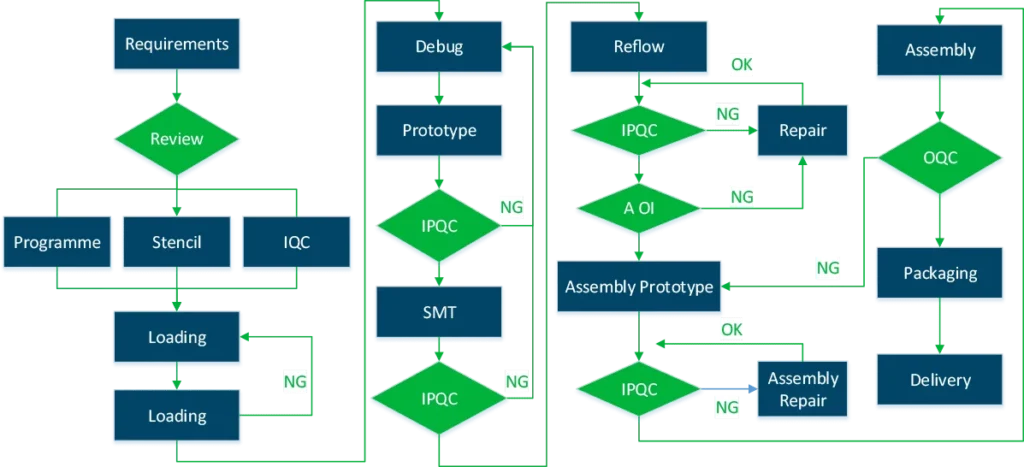

Most modern PCBs involve surface mount technology (SMT) and sometimes through-hole technology (THT) for connectors or power components. But handling both correctly? That’s where many cheap manufacturers fail.

Common issues:

-

SMT: Poor paste application, pick-and-place errors, inconsistent reflow profiles

-

THT: Cold joints, manual soldering mistakes, insufficient flux cleaning

At Unit Circuits, our SMT and THT assembly services in China are handled in one facility using automated inspection systems and IPC-trained operators — which ensures cross-process consistency.

This helps eliminate mismatches that often occur when different suppliers handle SMT and THT separately.

The Problem with No Testing: Who Pays When Boards Fail?

Many “cheap PCB assembly” providers exclude testing to keep prices low.

But skipping in-circuit testing (ICT) or functional circuit testing puts the risk squarely on the buyer.

Imagine powering on a 200-board run, only to find 15% are DOA due to a wrong resistor value or unconnected ground plane. Now you’re debugging someone else’s soldering error.

That’s why we include functional testing options — even for small batches — as part of our cheap turnkey PCB assembly with testing solution.

You get:

-

Flying probe testing

-

Functional jig setup

-

Custom test firmware flashing

-

Optional burn-in or high-temp cycle tests

No surprises. No rework later.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

Turnkey PCB Assembly Service vs Fragmented Sourcing

Here’s what happens when you manage sourcing yourself:

-

BOM quote delays from multiple vendors

-

Components out-of-stock mid-cycle

-

Confusion over packaging formats (cut tape vs reel)

-

Mismatched production schedules between fab and assembly

-

No one takes responsibility when boards fail

Instead, turnkey PCB assembly services handle everything from sourcing to shipping, all in one place — like we do at Unit Circuits.

Our one stop PCB assembly China with components sourcing service reduces touchpoints, ensures traceability, and gives engineers more time to engineer — not chase vendors.

How to Find a Reliable PCB Assembly Manufacturer in China

Not all suppliers are created equal — and many engineers don’t know what to look for. Here’s a quick reliability checklist:

✅ IPC certification (Class 2 or 3)

✅ Dedicated English-speaking support

✅ Transparent BOM review process

✅ Testing and QA included (not optional)

✅ Documented lead times and change control

✅ Support for SMT and THT assembly services in China

✅ Evidence of functional testing on request

Red flags? Unrealistically fast delivery promises, vague replies, no test procedures, or refusal to share factory photos/videos.

Don’t just trust a quote — verify capabilities on-site. This step-by-step SMT factory audit guide shows what to inspect before choosing a PCB assembly partner in China.

At Unit Circuits, our engineers offer pre-production DFM/DFA support, component cross-checks, and full production traceability.

The Case for No MOQ PCB Assembly: Why Prototyping Demands Flexibility

Hardware prototyping is unpredictable. You might need 3 boards for testing, then 30 more the next week — but many vendors say no to low volumes.

That’s why we offer no MOQ PCB assembly, whether it’s 1 board or 100.

Ideal for:

-

IoT device prototyping

-

Early-stage hardware startups

-

Industrial R&D labs

-

Designers building MVPs

Even better, our low volume PCB assembly with no MOQ still includes:

-

Sourcing support

-

Mixed SMT + THT

-

Test options

-

Fast lead times (from 5–7 working days)

Why Full Service PCB Assembly Is Critical for Hardware Startups

Startups need more than a soldering line. They need speed, support, and flexibility.

We’ve seen it all: BOM changes mid-order, datasheet corrections, emergency re-spins.

That’s why our full service PCB assembly for hardware startups includes:

-

BOM management and sourcing advice

-

Rapid prototyping cycles

-

Rework and patching options

-

Engineering change request (ECR) support

-

Early feedback on layout or manufacturability

We’re not just an assembly line — we’re your electronics manufacturing partner.

Fast PCB Assembly with Functional Testing: A Competitive Advantage

In today’s fast-moving product cycles, speed + quality is everything. That’s where our fast PCB assembly with functional testing shines.

You can:

-

Validate prototypes faster

-

Ship beta units with confidence

-

Hit investor deadlines

-

Fix design issues before scale-up

Every board undergoes either AOI, X-ray, or functional circuit testing — even small batches — because we believe startups deserve the same quality as Fortune 500s.

The Unit Circuits Advantage: Solving the Industry’s Toughest Challenges

Let’s face it — PCB buyers today face real problems:

| Problem | Our Solution |

|---|---|

| Cheap providers skip testing | ✅ Functional testing included |

| Hard to source components | ✅ BOM review + sourcing support |

| Mixed SMT + THT issues | ✅ Integrated line, IPC-trained staff |

| No MOQ support | ✅ Accept small batches |

| Slow response or poor support | ✅ English-speaking engineers |

| Unstable lead times | ✅ Transparent delivery timelines |

We specialize in cheap turnkey PCB assembly with testing, done right — with no compromises. Our QA process detects early-stage failures such as open circuits or cold joints, which are among the most critical PCB defects as outlined in this IEEE study.

FAQs

1. What makes a PCB assembly partner truly reliable for long-term projects?

A reliable PCB assembly partner offers consistent quality, responsive support, and full process transparency. Look for companies with strong PCB quality control, proven lead time performance, and flexibility to scale from prototype PCB build to production. Choose partners who understand your product lifecycle — not just your current order.

2. Can I get fast and affordable PCB assembly for industrial devices?

Yes. We provide fast PCB assembly with functional testing designed for industrial PCB assembly needs. You’ll benefit from fast turnaround times, durable component sourcing, and full electrical testing to ensure reliability in demanding environments — all while keeping costs competitive with affordable PCB manufacturing and assembly.

3. Do you support electronics contract manufacturing beyond PCB assembly?

Absolutely. We offer complete electronics contract manufacturing, including component sourcing service, enclosure assembly, cable harnesses, and final product testing. This full-service approach streamlines your supply chain, shortens lead times, and allows you to focus on R&D and scaling.

4. How do you manage small batch PCB production with no MOQ?

Our small batch PCB production model is ideal for prototyping, niche devices, or pilot runs. With our no MOQ PCB assembly policy, you can order as few as one unit, while still receiving professional testing, BOM support, and dedicated engineering service — without inflated per-unit pricing.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary: Don’t Let a Cheap Quote Cost You a Fortune

Don’t let a low quote lead to high costs. Ask the right questions, demand proper testing, and partner with experts who value long-term success — not shortcuts. Ready to build better boards, faster? Let’s talk.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!