Quick Leads

How Do E-Test Fixtures Adapt to Diverse PCB Sizes and Shapes?

Introduction

When you make PCBs, you have to test them to make sure they work and are good. People who make PCBs and test them use E-test fixtures to test all kinds of PCBs that are different sizes and shapes. But how do these fixtures work with all these different PCBs? This article tells you how E-test fixtures work with different sizes and shapes of PCBs and what’s good and bad about different kinds of fixtures.

How E-Test Fixtures Adapt to Complex PCB Shapes and Sizes

E-test fixtures work with different sizes and shapes of PCBs by using special probes and setups that can change to touch the test points on the PCB, no matter what it looks like.

If the PCB is weird or complicated, you can make the E-test fixture work with it by changing it to use a bed-of-nails or flying probe system, which helps you change it and save money. This way, you can make sure your PCBs are good, no matter what they look like.

What is an E-Test in PCB Manufacturing?

E-testing, or electrical testing, checks to see if all the electrical connections in a PCB are right, based on the design’s drawing. The test uses information from a file called a “netlist” to find any shorts, opens, or things that aren’t lined up right, so you can catch problems early.

If you test your PCBs right, you won’t have as many problems with the stuff you make, and your PCBs will work the way they’re supposed to.

How E-Test Fixtures Adapt to PCB Sizes and Shapes

PCBs can be small and packed with stuff, like in things you wear, or big and complicated, like in machines. E-test fixtures can work with all different kinds of PCBs because they’re made to change:

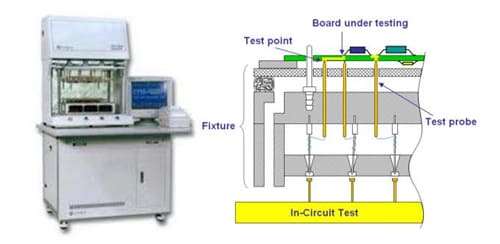

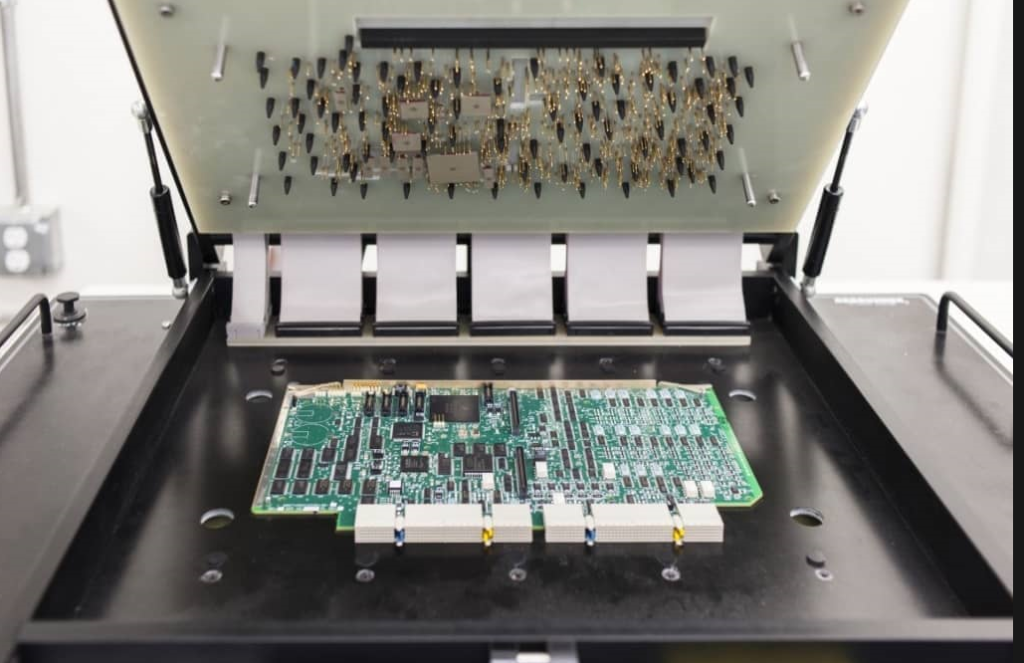

1.Bed-of-Nails (Nail-Based Fixtures): These fixtures use a bunch of pins that touch the test points on a PCB, so they’re good for making a lot of the same thing.

2.Custom Fixtures for Unique Designs: Custom fixtures let you move the pins so they touch the test points on PCBs that aren’t the same as all the others. This is good for PCBs that are complicated or big.

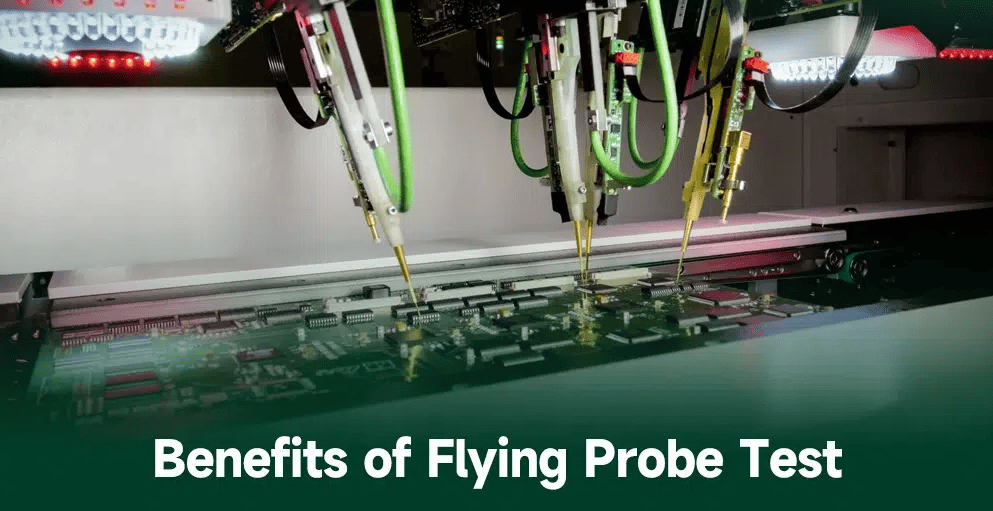

3.Flying Probe Systems: If you’re making a few or just one PCB or you’re testing a prototype, you don’t need a special setup for flying probes. The probes move by themselves to touch the test points, so this way is good for PCBs that are different shapes, have small test points, or don’t have test points just for testing.

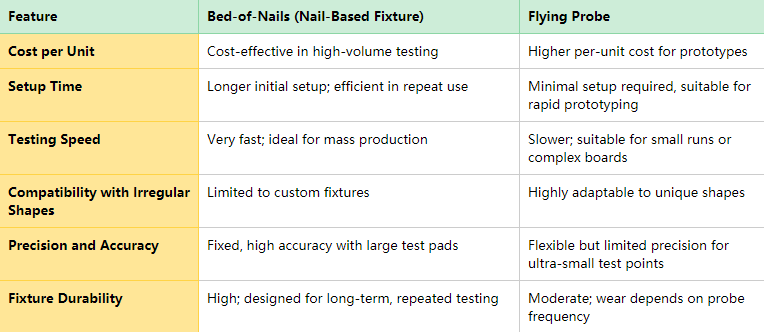

Detailed Comparison: Bed-of-Nails vs. Flying Probe

Here’s a comprehensive comparison to help PCB testing professionals determine the best fixture type for their needs:

Key Parameters in PCB Electrical Testing

To make sure that a PCB is good, E-testing looks at a few things:

- Voltage Tolerance: Checks to see if the board can handle the amount of electricity it’s supposed to without breaking.

- Isolation Resistance: Makes sure that the parts are far enough apart so they don’t touch each other and cause a problem.

- Continuity Resistance: Checks to see if the stuff on the board that’s supposed to be connected is connected.

- Adjacency Testing: Keeps signals from crossing paths when they shouldn’t, so you don’t have to worry about signal interference in the real world.

User-Focused Solutions for Common PCB Testing Challenges

When you’re testing PCBs, you run into problems that can slow you down and make your results less reliable. Here are some of the most common problems and what you can do about them.

- 1.Reliable Connections on High-Density PCBs:

- Challenge: Ensuring reliable connections on densely populated boards.

- Solution: Consider using higher pin density fixtures or integrating a hybrid testing approach (combining bed-of-nails with a flying probe) to reach difficult test points on compact boards.

- 2.Reducing Setup Time for Prototyping:

- Challenge: Prototypes often require rapid testing, but setup time can be a bottleneck.

- Solution: Opt for flying probe systems, which require minimal setup and allow fast adjustments to different board layouts. Using software-based test configuration can further streamline probe setup.

- 3.Fixture Maintenance and Consistent Quality Control:

- Challenge: Regular maintenance is necessary to ensure fixture accuracy.

- Solution: Establish a cleaning and inspection schedule to prevent contact issues. Pins should be replaced as they wear down, and any signs of misalignment should be addressed immediately to prevent inaccurate test results.

- 4.Design Challenges Affecting Testability:

- Problem: Boards designed without accessible test points complicate fixture alignment.

- Solution: During the PCB design phase, include larger or well-positioned test points to improve test efficiency and fixture compatibility. Early-stage design considerations can greatly simplify testing later.

Industry-Specific Testing Applications

Different industries have unique demands for PCB testing. Here’s how adaptable E-test fixtures serve these varied requirements:

- Automotive Electronics: The automotive industry needs high reliability, so all PCBs have to be tested really well. Bed-of-nails fixtures are great for testing automotive boards because they’re fast and can keep up with the fast pace of making the same board over and over again.

- Medical Devices: Medical devices have to be really precise because they’re so small and have parts that are really sensitive. Flying probes are great for testing medical boards because they don’t touch the board and can go anywhere on the board.

- Consumer Electronics:When you’re making consumer electronics, you need to make them fast and cheap. Bed-of-nails fixtures are great for testing consumer boards that you make a lot of because they’re fast and let you make a lot of boards without worrying about quality.

Looking for tailored solutions for your unique PCB design? Speak with an E-test expert today to optimize your testing setup and ensure every board meets rigorous standards.

For more information, visit below:

For more insights on Complete Guide on PCB Assembly E-Test Fixture, check out: Test fixture

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

E-test fixtures can be customized to work with all different shapes and sizes of PCBs. You can use bed-of-nails fixtures or flying probes, depending on what you need to do. This lets you meet the standards for your industry and make sure your product is reliable.

Picking the right fixture and taking care of it are the most important things you can do to make sure you don’t make mistakes, make a good product, and make a lot of them.

Request for Quote

Assemble 20 PCBAS for $0

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!