Quick Leads-PCBA

Choosing the right type of solder for PCB assembly isn’t just a technical call—it can affect product reliability, regulatory compliance, and production cost. I’ve worked with clients in aerospace, consumer electronics, and even medical devices who’ve faced issues from poor solder decisions. If you’re sourcing PCB assembly services or leading a team of engineers, this guide is designed for you.

Lead solder offers better workability and durability under high-stress applications, while lead-free solder is safer, RoHS-compliant, and preferred for modern electronics manufacturing. Your decision depends on industry requirements, reliability expectations, and environmental standards. For aerospace and military? Lead might still be king. For consumer devices or export markets? Lead-free is often mandatory.

Now let’s get into the real-world engineering details, pros and cons, and why this choice isn’t just about solder—it’s about your product’s future.

Which is better, lead or lead-free solder?

The classic debate: performance vs. compliance. Let’s look at the real differences between lead and lead-free solders from a practical engineering perspective.

🔧 Composition

Lead-based solder: Typically 63/37 tin-lead alloy. Melts at around 183°C.

Lead-free solder: Usually tin-silver-copper (SAC305), melting at ~217–221°C.

🔍 Practical Impact

| Property | Lead Solder | Lead-Free Solder |

|---|---|---|

| Melting Point | ~183°C | ~217–221°C |

| Workability (Wettability) | High | Medium |

| Joint Durability | More ductile | More brittle |

| Toxicity/Health Risk | High | Low |

| RoHS Compliant | ❌ No | ✅ Yes |

| Cost | Lower | Higher |

Lead solder gives you smoother joints and easier hand soldering. But it’s toxic. Lead-free solder is cleaner and globally accepted, but requires tighter process control.

For a deeper technical breakdown of melting points and usability, NextPCB offers a detailed comparison that echoes many of the findings above.

What solder is used in PCB assembly today?

If you’re asking what solder is used in PCB assembly, the short answer is: it depends on where and what you’re building.

🌐 Global Trend

Consumer electronics: Lead-free solder PCB assemblies are now standard.

High-reliability sectors (e.g., aerospace): Lead-based still dominates, due to better solder joint reliability.

🔩 Common Solder Alloy Types for PCB

| Solder Type | Composition | Best For |

|---|---|---|

| Sn63Pb37 | Tin-Lead | Military, industrial |

| SAC305 | Tin-Silver-Copper | Consumer, medical, export |

| Sn96.5Ag3.0Cu0.5 | High-purity lead-free | Automotive, telecom |

Modern EMS factories in China (including ours) often support both types, depending on your BOM requirements and PCB assembly process preferences.

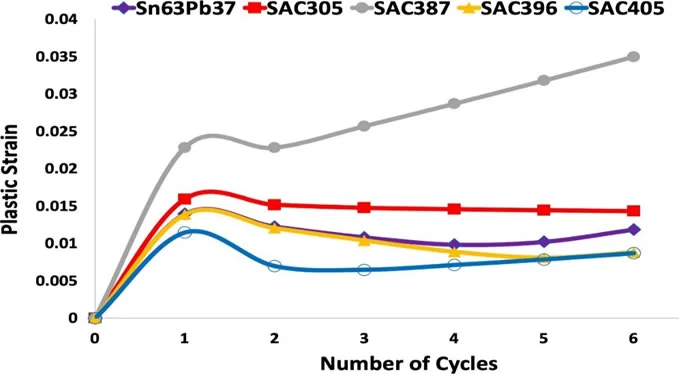

What are the reliability issues with lead-free solder?

If you’ve ever worked with lead-free PCB assembly, you probably already know—it’s not all roses.

🔍 Common Reliability Issues

Micro-cracks during thermal cycling due to higher melting points

Weaker wetting properties, making it harder to ensure full pad coverage

Solder joint reliability can suffer over time due to increased brittleness

👨🔬 Our Fix

We’ve optimized our reflow soldering and wave soldering lines to handle these challenges. For example:

Controlled nitrogen environments during reflow

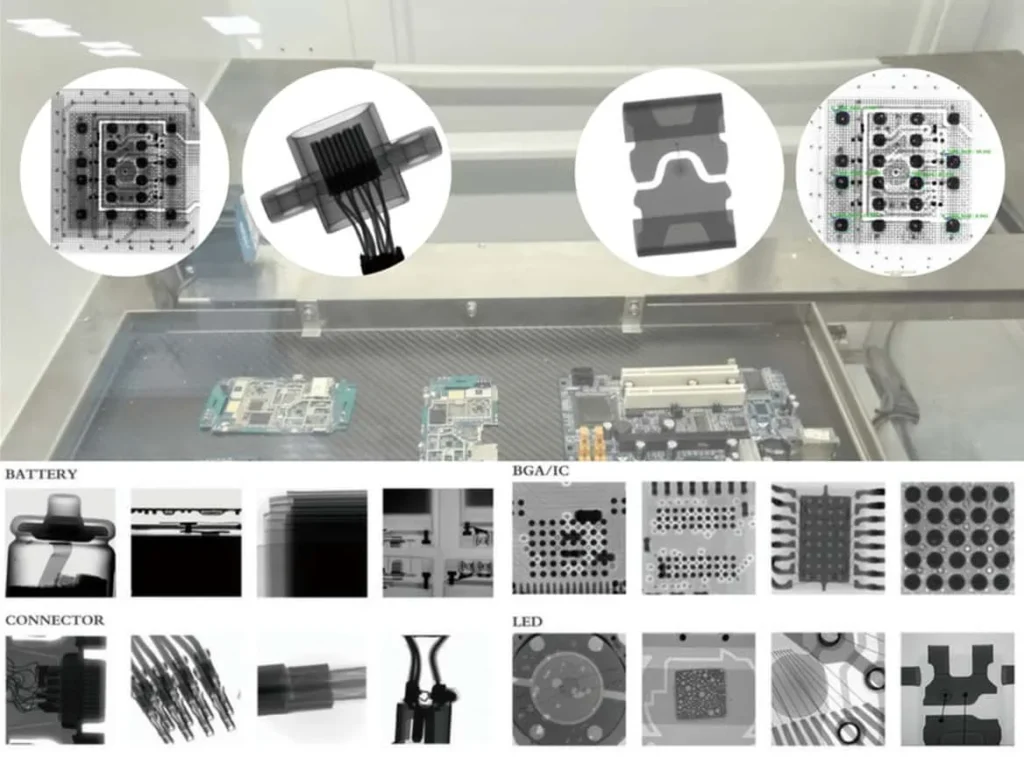

X-ray and AOI inspection for voids and poor joints

Custom profiling to adjust ramp rates

If you’re sourcing from a China EMS provider, always ask: how do you ensure reliability with SAC alloys? Not everyone invests in this level of process control.

Soldering issues like cold joints and micro-cracks are more likely with lead-free alloys. These challenges can be addressed through proper inspection and profiling. Learn how to detect and prevent common soldering defects in PCB assembly to ensure long-term reliability—especially with RoHS-compliant processes.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Is lead solder banned in electronics globally?

The answer? Not entirely—but it’s close in many regions.

🌍 Compliance Landscape Chart

| Region | Regulation | Lead Allowed? |

|---|---|---|

| EU | RoHS | ❌ Only in exemptions |

| USA | Varies (EPA/FDA) | ✅ Allowed in some |

| China | RoHS-like GB/T | ❌ For consumer goods |

| Military | Defense standards | ✅ Widely used |

RoHS compliant PCB assembly is now essential if you’re shipping into the EU or Asia. Even in the US, the move toward environmental regulations is accelerating.

So if you’re asking, “Is lead solder banned in electronics?”—it’s mostly restricted unless you’re working in legacy or defense sectors.

If you’re balancing environmental regulations with performance, this overview on Wevolver helps explain the policy backdrop and materials science.

Which solder type is best for your application?

Let’s map solder choice to application types. It’s not just about regulation—it’s about product lifecycle and environment.

| Application Type | Recommended Solder Type | Why? |

|---|---|---|

| Aerospace / Defense | Tin-Lead (63/37) | Superior fatigue resistance |

| Consumer Electronics | SAC305 / Tin-Silver-Copper | RoHS compliance, low toxicity |

| Automotive | SAC-based with additives | Vibration and temperature stable |

| Medical Devices | Lead-Free (high purity) | Compliance-critical |

| Industrial Controls | Mixed (customer preference) | Often legacy systems involved |

Need lead-free PCB assembly in China? We support complete RoHS lines, IPC-A-610 Class 3 inspection, and documentation for global markets.

Industry Pain Points—and How We Solve Them

Here’s where things get interesting. Most of our clients struggle with:

1. Thermal Damage from High Reflow Temps

-

Lead-free solders can stress sensitive components

-

Our Solution: Thermal profiling + active cooling during reflow

2. Inconsistent Joint Quality

-

Especially common in lead-free prototypes or mixed-metal assemblies

-

Our Solution: AOI, X-ray inspection, and skilled rework engineers

3. Compliance Documentation

-

Especially when dealing with export controls and safety certifications

-

Our Solution: Full RoHS compliant PCB assembly support with traceability

Working with a flexible China EMS provider like us means you’re not stuck in a one-size-fits-all process.

Should I always go lead-free? Practical takeaways.

Here’s my honest take, based on years in the field:

-

Go lead-free if you’re building consumer or export-oriented products

-

Stick with lead if reliability and mechanical stress are your top priorities

-

Ask your EMS partner if they support both and understand the tradeoffs

Choosing between lead vs. lead-free solder isn’t about trends—it’s about your design intent, compliance needs, and customer expectations.

FAQs

1. Can you mix lead-free and lead solder in the same PCB assembly?

Mixing lead and lead-free solder is not recommended. It can cause inconsistent melting points, weak joints, and reduced solder joint reliability. If your PCB design or components include mixed requirements, consult your EMS provider early. A RoHS compliant PCB assembly should always avoid cross-contamination to meet export regulations and ensure consistent performance.

2. Why is lead-free solder more brittle in high-vibration environments?

Lead-free solder, especially tin-silver-copper alloys, forms harder but less ductile joints. In high-vibration applications like automotive or aerospace, this can lead to cracking or fatigue failure. Engineers must account for this brittleness during the PCB assembly process with enhanced thermal profiling and joint inspection. Choosing the right solder alloy type for PCB reliability is critical.

3. Do I need special flux when working with lead-free solder?

Yes, lead-free solder typically requires a more active or higher-temperature flux to ensure proper wetting and oxidation control. Standard rosin fluxes used with leaded solder may not perform well with lead-free compositions. For best soldering results and to prevent bridging or cold joints, always match your flux to the solder alloy type.

4. Is lead-free PCB assembly more expensive?

Generally, yes. Lead-free PCB assembly involves higher material costs (like silver in SAC305), elevated reflow temperatures, and stricter process controls. However, it’s often the only option for exporting to RoHS-regulated markets. Investing in lead-free compliance today prevents costly redesigns and opens your product to global distribution.

While lead-free options are more compliant, they often raise costs due to higher alloy prices and reflow temperatures. This guide breaks down 10 key factors that affect PCB assembly cost and shows where you can still save—even with RoHS-compliant production lines.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion

Choosing the right solder is critical to building reliable, scalable electronics. Hopefully, this guide helped clear up the technical fog.

We’ve built everything from IoT gadgets to aerospace controllers—and every solder choice came with unique tradeoffs. If you’re still unsure which is right for your build, just reach out. We’ll talk tech, not just price.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!