Quick Leads-PCBA

Struggling to find a reliable LED PCB supplier who actually understands thermal design, fast prototyping, or low-volume production? You’re not alone. Many engineers hit roadblocks with cheap builds or late deliveries. In this guide, I’ll walk you through LED PCB design, assembly, and how we solve industry-specific problems.

An LED PCB is a printed circuit board designed to power and mount light-emitting diodes (LEDs). These boards are specially built to handle high heat and power loads. LED PCBs often use materials like aluminum for better thermal conductivity and are used in lighting, automotive, and industrial applications. Their design involves heat dissipation, efficient circuitry, and mechanical stability, making them essential for energy-efficient electronics.

Let’s dive into the real nuts and bolts of LED PCBs — from materials and design rules to common manufacturing challenges and what sets a truly reliable assembly partner apart.

🔧 What Is an LED PCB, and How Does It Work?

An LED PCB (Printed Circuit Board for LED) is the backbone of LED lighting technology. Instead of wiring individual LEDs manually, we embed them directly into a PCB for automation, durability, and space-saving benefits.

🔎 Where LED PCBs Are Used:

-

Commercial & industrial lighting

-

Automotive headlamps and dashboards

-

Smart home lighting

-

Medical devices and wearables

-

Outdoor signage and billboards

💡 Types of LED PCBs

| Type | Material | Application | Key Benefit |

|---|---|---|---|

| Aluminum LED PCB | Aluminum base | High-power LED lighting | Superior heat dissipation |

| FR-4 LED PCB | Fiberglass | General electronics | Cost-effective |

| Ceramic LED PCB | Ceramic | Medical & high-frequency use | Excellent thermal & electrical performance |

| Flexible LED PCB | Polyimide | Wearables & dynamic lighting | Bendable, compact |

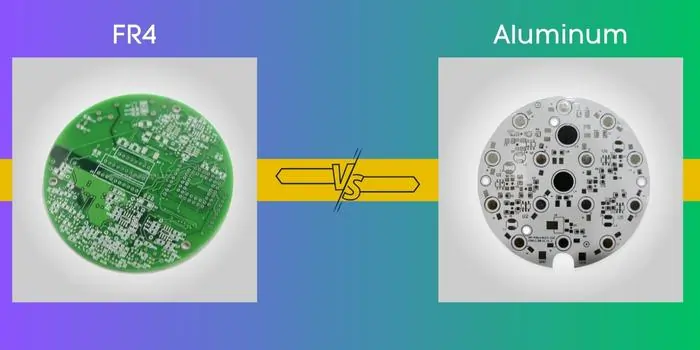

These material choices significantly impact performance — especially thermal management, which is a key concern in LED circuit design.

🔍 LED PCB vs. Traditional PCB: What’s the Difference?

Many engineers ask if they can use traditional FR-4 boards for LEDs. Short answer: you can, but don’t expect optimal performance.

🆚 LED PCB vs. Traditional PCB

| Feature | Traditional PCB | LED PCB |

|---|---|---|

| Heat Resistance | Moderate | High |

| Base Material | FR-4 or CEM-1 | Aluminum, ceramic |

| Thermal Conductivity | Low | High |

| Surface Treatment | HASL, ENIG | ENIG, OSP, Immersion Silver |

| LED Mounting Suitability | Limited | Purpose-built |

Aluminum LED PCBs shine in high-brightness or power-dense applications. They manage heat better and ensure longer LED lifespans.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

📐 LED PCB Design Guidelines You Shouldn’t Ignore

Getting the layout right is everything. Poor trace routing or bad thermal design leads to burnout or flicker. For a deeper dive into layout techniques, DigiKey outlines essential PCB design rules like avoiding right-angle traces and optimizing copper pour zones.

🔧 Our Go-To Design Checklist:

Wide traces to reduce voltage drop

Copper pour zones for heat spreading

Thermal vias for heat transfer

Component spacing to allow airflow

Thicker copper (up to 2 oz) for high current

Solder mask over via to prevent bridging

Via hole plating and via protection techniques to boost reliability

Thermal design isn’t a “nice to have” — it’s life or death for your LEDs.

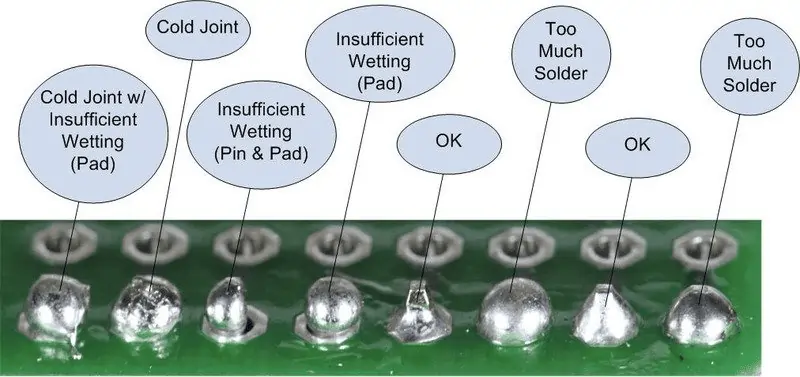

⚠️ Common Challenges in LED PCB Manufacturing — And How We Solve Them

LED boards aren’t easy to produce — even major EMS companies get it wrong. Here’s what we’ve seen over the years.

😩 Common Industry Pain Points:

Warping during reflow due to poor board material

Inconsistent surface finishes

Overheating due to lack of thermal vias

Long lead times or “ghosting” on low-volume orders

✅ How We Fix It:

| Issue | Our Solution |

|---|---|

| Board Warping | Use high-grade aluminum with flatness guarantee |

| Thermal Issues | Integrate thermal vias + copper pour + aluminum base |

| Inconsistent Quality | AOI + X-ray + ROHS-certified process |

| MOQ Problem | No minimum order, real-time quote system |

🛠️ Issues vs. Our Solutions embedded above.

We’re not just a fab house — we act as an extension of your engineering team. We’ve seen these problems firsthand — from solder bridges to LED burnout. Here are 8 of the most common PCB assembly problems and how to fix them, which can help you avoid major reliability issues in LED lighting projects.

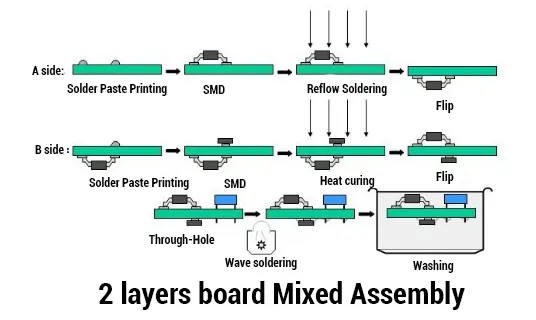

🛠️ The Full LED PCB Assembly Process Explained

Here’s what our turnkey LED PCB assembly process looks like:

Stencil printing: Apply solder paste to SMD pads

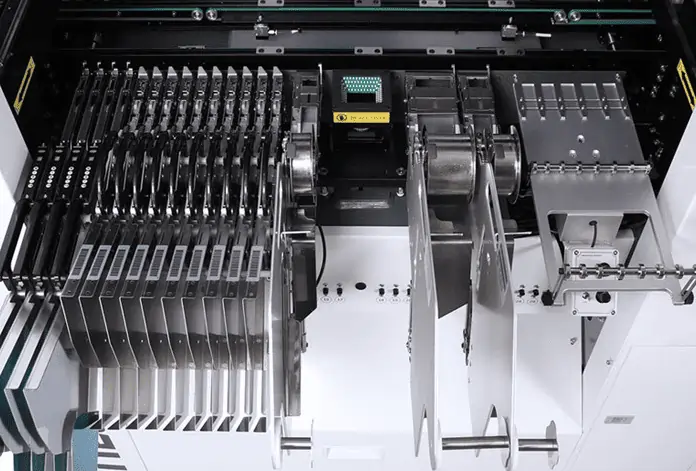

SMT pick and place: Mount LEDs and other components

Reflow soldering: Controlled heating to create strong joints

THT assembly (if needed): Hand or wave soldered

Testing: AOI, X-ray, ICT, LED light test

Final inspection: Visual + ROHS compliance

💡 We use lead-free solder, ROHS LED PCBs, and advanced surface mount assembly to ensure performance.

🧭 Custom LED PCB Manufacturer: What to Look for in 2025

Anyone can solder a few LEDs. But if you’re scaling or building something critical, here’s what really matters.

🛠️ Checklist for a Quality Manufacturer:

In-house DFM/DFA engineering

Thermal simulation support

Experience with surface mount LED PCB

Turnkey capabilities (fab + assembly + test)

Bilingual support (for China-based partners)

🆚 Local Manufacturer vs. Turnkey China EMS Partner

| Feature | Local Supplier | Our China-Based EMS |

|---|---|---|

| Cost | High | Competitive |

| Prototyping Speed | Moderate | Fast-turn |

| Component Sourcing | Limited | Global database |

| Engineering Support | Varies | DFM + thermal design |

| MOQ | High | No minimum |

We combine fast LED PCB quotes, no MOQ, and deep industry experience into one workflow. Working with a one-stop shop streamlines everything — from DFM to testing. Here’s how turnkey PCB assembly services can transform your manufacturing process and help you scale faster without compromising quality.

🚀 From Prototype to Production: Low Volume LED PCB Manufacturing

Need just 50 units to validate your new LED lighting design? No problem.

We specialize in:

LED PCB prototyping services

Small batch runs with no minimum order

Same-line transition to volume production

This helps you avoid “lab success, factory failure” — one of the biggest pitfalls in product development. Whether you’re prototyping 20 boards or scaling to 10,000, cost control is key. This guide on how to save money in PCB assembly walks through material selection, yield rates, and setup fees that impact your bottom line.

⚡ Need It Fast? How to Get a Fast LED PCB Quote

The quoting phase slows down most companies. Not here.

Here’s how to speed things up:

Upload Gerber + BOM + pick-and-place file

Specify final use (we auto-suggest materials)

Get real-time pricing across 3 builds (prototype, low-vol, full)

No back-and-forth. No ghosting.

We offer fast-turn PCB assembly and real-time tracking for your builds.

💡 Case Study: Aluminum LED PCB for Lighting Applications

One of our clients — an EU-based LED lighting startup — needed aluminum LED PCBs with zero warping and perfect thermal balance.

They were launching a linear LED light for commercial ceilings.

What we delivered:

1.6mm aluminum base

2 oz copper

Immersion silver finish

Full turnkey assembly with SMT LEDs and drivers

Result? Passed UL & CE, shipped in 9 days. Reliability was 99.8% after 6 months.

FAQs

1. What is a PCB in lighting, and why is it important?

A PCB in lighting is a specialized circuit board that powers and connects LEDs in lighting systems. Unlike standard PCBs, LED lighting PCBs are designed to handle high heat and power loads. Using the right PCB ensures your lights last longer, stay energy efficient, and don’t overheat. Poor-quality PCBs often lead to early LED failures and increased maintenance costs — especially in high-output applications like industrial lighting.

2. How to make an LED PCB that doesn’t overheat?

To build an LED PCB that won’t overheat, you need proper thermal management in LED PCB design. Start with an aluminum base material, use thermal vias, and design wide copper traces. Always calculate your thermal resistance and power budget. Partnering with a custom LED PCB manufacturer also helps you avoid early failures, flickering, and performance drops — common pain points we’ve solved for hundreds of clients.

3. What is the problem with PCB in electronics manufacturing?

In electronics manufacturing, PCB problems often include warping, delamination, poor solder joints, and inefficient layouts. These lead to product recalls, overheating, and low reliability. For LED PCB assembly, the biggest issue is poor heat dissipation, which kills LED lifespan. A well-executed turnkey LED PCB assembly service fixes this by integrating DFM (Design for Manufacturability) and thermal simulation before production.

4. Where is LED PCB commonly used — and how does it affect cost?

LED PCBs are commonly used in lighting, automotive electronics, consumer gadgets, and industrial controls. In each case, the design must match the environment. For example, aluminum LED PCB for lighting offers better heat control but costs more than standard FR-4. Choosing the wrong PCB type can increase failure rates and warranty returns. A fast LED PCB quote system helps you balance performance and cost before going into production.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🧩 Conclusion

LED PCB tech is constantly evolving — and it pays to partner with a manufacturer who understands both the design and execution side. If you’re building next-gen lighting or displays, we’d love to help. Hit us up for a fast LED PCB quote or a free design review.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!