Quick Leads

How to Choose the Best ODM & OEM PCB Assembly Manufacturers for High-Volume IoT Products

As an IoT company, choosing the right PCB assembly partner is critical to your product’s success. You need someone who can not only handle high-volume production but also ensure top-tier quality control for your smart devices. For companies like Shelly USA, who create innovative solutions for automating homes and buildings, finding the right ODM (Original Design Manufacturer) or OEM (Original Equipment Manufacturer) for PCB assembly is more than just about price—it’s about quality, reliability, and scalability.

In this article, we’ll take a deep dive into the world of turnkey PCB solutions, explain the differences between OEM and ODM services, and help you understand how to select the best PCB assembly manufacturer for your IoT products.

What is Turnkey PCB Manufacturing?

If you’ve been working in the IoT industry, you’ve probably come across the term turnkey PCB manufacturing. But what does it really mean? A turnkey solution is when a manufacturer takes care of everything involved in PCB production. This includes everything from component sourcing and circuit board assembly to final testing and packaging. The goal of turnkey manufacturing is to provide you with a fully completed PCB, ready to go, without you needing to deal with multiple suppliers or suppliers.

For companies like Shelly USA, this is an ideal approach because it simplifies the process of bringing products like their smart thermostatic radiator valves or IoT controllers to market. By opting for a turnkey solution, you only need to work with one manufacturer that will ensure both quality and speed, so your IoT devices can get to market quickly and at a competitive price.

The advantages of turnkey PCB manufacturing include:

- Streamlined process: One manufacturer, one solution. No need to coordinate with several suppliers.

- Cost-effective: Bulk buying of components and materials often leads to lower costs.

- Faster time-to-market: The entire process is handled in one place, reducing delays.

This service works great for high-volume IoT products where consistency and speed are paramount.

Kodiak Assembly – PCB Design for Internet of Things

This page highlights expert PCB design services tailored for IoT products, with an emphasis on reliability, functionality, and IoT-specific component selection.

What is OEM PCB Assembly?

Now, let’s talk about OEM PCB assembly. OEMs specialize in designing and manufacturing products or components for other companies under the original equipment label. When it comes to PCB assembly, this means outsourcing your PCB design and assembly to a trusted partner who handles everything from sourcing components to testing the final product.

In the world of IoT products, such as Shelly’s smart home devices, OEM PCB assembly is a great way to ensure high-quality, customized solutions for your devices. This is especially useful if you’re looking for precision and uniqueness, where working with an OEM means your product will have a custom-tailored PCB that meets all your technical and performance needs.

The benefits of OEM PCB assembly are:

- Expert design: OEM manufacturers bring extensive experience to custom PCB designs that are tailored specifically to your product.

- High quality: They ensure strict quality control during the assembly process.

- Scalability: Whether you need low-volume prototyping or mass production, OEMs can handle both.

For a company like Shelly USA, working with an OEM PCB partner ensures that every IoT device is designed and assembled to the highest standards, and that your product is ready for mass production without the headaches of dealing with multiple suppliers.

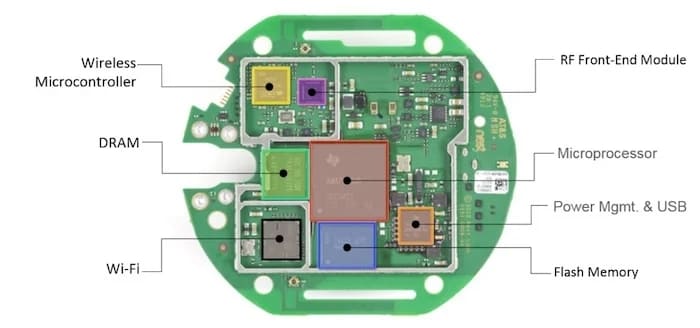

Sierra Assembly – IoT PCB Assembly

Learn about IoT PCB assemblies, including the functionality, connectivity, and intelligence of IoT devices, provided by Sierra Assembly.

What is the Difference Between PCB Assembly and PCB Manufacturing?

When you’re diving into the world of PCB assembly, it’s crucial to understand the difference between PCB manufacturing and PCB assembly. Simply put, PCB manufacturing is the process of creating the bare printed circuit board—the base layer that will hold all the components in place. This involves processes like etching, layering, and printing the circuit.

On the other hand, PCB assembly is the process where components—such as resistors, capacitors, chips, and connectors—are attached to the PCB to turn it into a functional electronic circuit.

In terms of IoT, both are crucial steps. For a company like Shelly USA, their products like smart thermostatic valves need not only high-quality boards (manufacturing) but also the right components and assembly (assembly) to function properly. For example, Shelly’s smart thermostatic radiator valve must be precise and durable, making the assembly process as important as the manufacturing stage.

Understanding the distinction between PCB manufacturing and PCB assembly helps you work more effectively with your PCB assembly partner, ensuring you get the best results in both areas.

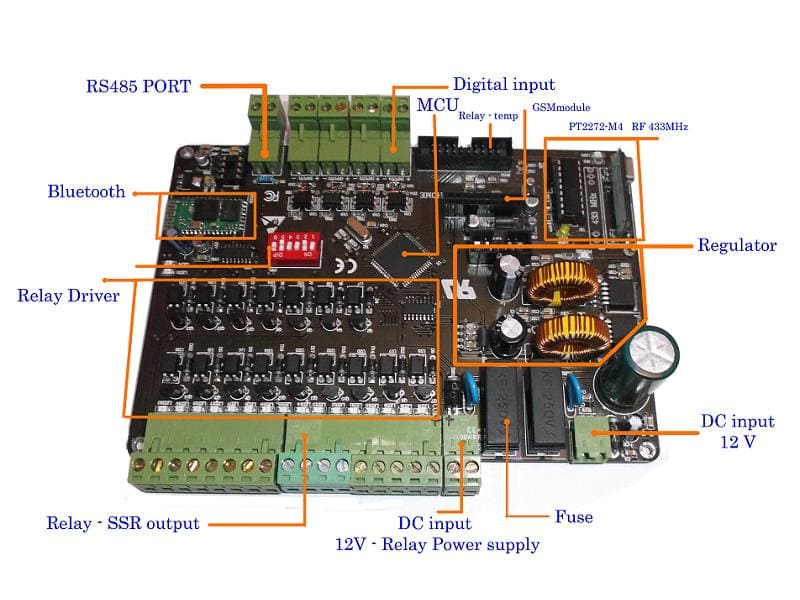

AalokTronix – PCB Assembly Services for IoT Devices

AalokTronix offers specialized PCB assembly services for IoT devices, using advanced techniques to produce efficient and reliable circuit boards.

Who are the Largest PCB Manufacturers in the World?

There are a number of large PCB manufacturers globally that specialize in high-frequency, multi-layer, and complex PCB designs, especially needed for advanced products like IoT devices. Some of the major players include:

- Unimicron Technology Corporation (Taiwan): One of the world’s largest PCB manufacturers, Unimicron is well known for handling high-end, multi-layer PCB projects.

- Zhen Ding Technology (China): Specializing in flexible PCBs, Zhen Ding serves a range of industries, including IoT and consumer electronics.

- Compeq Manufacturing Co. Ltd. (China): Another major PCB supplier, Compeq is known for delivering high-quality, high-volume PCBs for the consumer electronics sector.

For IoT companies like Shelly, it’s essential to choose a PCB assembly manufacturer that has experience working with high-tech, high-volume products and understands the specific requirements of the IoT market. Look for manufacturers that can handle complex designs, customized solutions, and scale production effectively.

POE PCBA – Internet of Things PCB Manufacturing & Assembly

Explore POE’s IoT PCB assembly services, including global component procurement and high-quality PCB manufacturing tailored for the Internet of Things industry.

How Do I Find the Best Turnkey PCB Assembly Provider for My IoT Product?

Finding the best turnkey PCB assembly provider for your IoT product can be daunting, but focusing on a few key factors will help simplify the process:

- Experience with IoT: Look for providers who have experience working with smart devices, wearables, and other IoT products. They’ll have the expertise to meet your specific needs.

- Global supply chain: A strong global network for sourcing components is crucial for ensuring consistency and cost-efficiency.

- Flexibility and scalability: Ensure the provider can handle everything from low-volume prototypes to high-volume mass production.

- Quality control: A rigorous testing process is a must for ensuring that every unit produced meets the necessary standards.

Choosing the right turnkey PCB assembly provider ensures your IoT devices are manufactured efficiently and meet the highest quality standards—important for companies like Shelly that rely on precision and innovation in their products.

What Are the Benefits of ODM PCB Assembly for IoT Products?

Opting for an ODM PCB assembly service can significantly benefit your IoT products, especially if you’re looking for custom designs and high-quality manufacturing. Here’s how ODM services work for companies like Shelly USA:

- Tailored designs: ODMs specialize in creating custom PCBs that perfectly fit the specific needs of your product, whether it’s a smart thermostat or a wearable.

- End-to-end services: ODMs handle everything from design to assembly, meaning you can focus on what you do best: innovation and marketing.

- Cost-efficiency: By working with an ODM, you can often take advantage of bulk purchasing and streamlined production, which can save you money in the long run.

For Shelly, an ODM can take the burden off your team by managing all aspects of PCB design and assembly, allowing you to focus on scaling your smart IoT devices.

FAQs

A reliable PCB assembly provider should have certifications (like ISO 9001) and a proven track record of delivering quality products on time. Look for manufacturers who provide case studies or client testimonials to back up their claims. Also, ask about their quality control process to ensure that your products will meet the necessary standards.

Yes! Most turnkey PCB assembly providers specialize in handling both low-volume prototypes and high-volume production. When choosing a provider, confirm that they can scale production without compromising quality or timeliness. Shelly USA, for example, would need a partner who can handle large orders while ensuring the reliability of each unit.

When selecting an OEM PCB assembly partner, you should prioritize their ability to provide custom solutions, a strong supply chain, and a robust testing process. This ensures that your IoT product will be built to your exact specifications and perform well over time.

The time it takes to complete PCB assembly can vary depending on factors like complexity, quantity, and testing requirements. Typically, low-volume prototypes can be completed in a few weeks, while mass production can take a few months. Always work closely with your PCB assembly partner to set clear timelines for delivery.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary:

Choosing the right PCB assembly partner is essential for the success of your IoT product. By focusing on experience, scalability, and quality control, you can find a reliable OEM or ODM partner who will help you bring your smart devices to life. Whether you’re building smart thermostatic valves or wearable IoT devices, finding a trusted PCB manufacturer will ensure your product meets the highest standards.

If you’re ready to take your IoT product to the next level, reach out to us today for expert PCB assembly solutions tailored to your needs!

Have Specific Requirements?

We’re here to help! Whether it’s a custom PCB design, assembly, or sourcing components, feel free to reach out to us directly. Our team is ready to provide tailored solutions for your project. Contact Us Today for more information.Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!