Quick Leads

What Are the Key Components of a Circuit Board for IoT Devices?

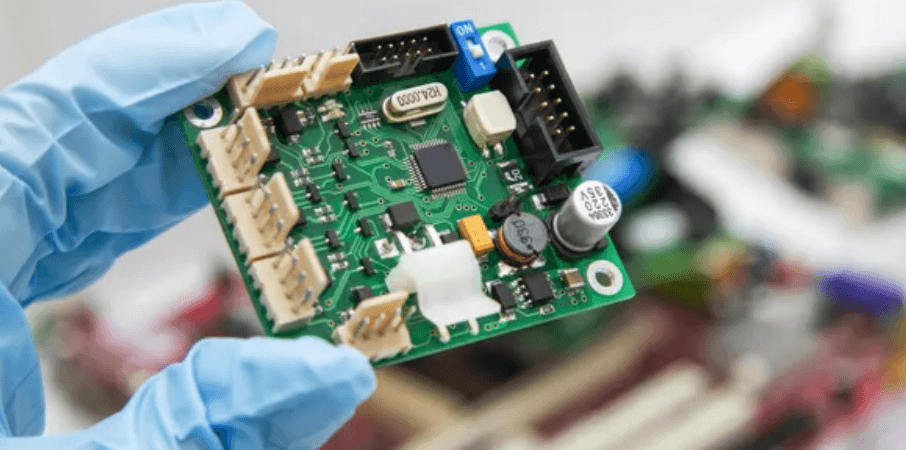

If you’re involved in developing high-quality IoT devices like Shelly’s smart thermostatic radiator valve, you’re probably already aware that understanding PCB components is the key to ensuring your product is both reliable and efficient.

Whether you’re dealing with simple, high-volume devices or more intricate designs, knowing how each component of a printed circuit board (PCB) functions will set you up for success. In this article, we’ll walk you through the essential PCB components for IoT devices and how partnering with the right PCB assembly service can take your products to the next level.

What is a PCB in IoT?

When we talk about PCBs in IoT, we’re referring to the foundation of most electronic devices. The PCB not only serves as a base for mounting all the necessary components but also facilitates the electrical connections that make your device work. Without a well-designed PCB, an IoT product like Shelly’s smart thermostatic radiator valve wouldn’t function properly.

At its core, the PCB ensures the physical layout of the device and allows for data processing, communication, and connectivity. These are essential for IoT devices that need to perform tasks like temperature control, wireless communication, and remote monitoring.

Think of the PCB as the skeleton of your device, without which all the electronic components would have nowhere to go or wouldn’t work together as efficiently.

What Are the Components of a PCB Assembly?

So, what exactly goes into a PCB assembly? A well-designed PCB contains a variety of active and passive components that work together to make your IoT device function as expected. Let’s break down the key parts:

-

Microcontrollers (MCUs): These tiny yet powerful processors act as the “brain” of the IoT device. The MCU processes all the data coming from the sensors and controls the actions of the device. For Shelly’s smart thermostatic radiator valve, the MCU would process temperature data and adjust settings accordingly.

-

System-on-Chip (SoC): This is an integrated circuit that includes a microcontroller, memory, and other essential components, all packed into one. For IoT devices, SoCs are perfect because they combine the power of a microcontroller and other functionalities into one compact package, helping to save space and power.

-

Capacitors and Resistors: These are passive components that regulate voltage, filter out unwanted signals, and manage the flow of electricity to other components. A good balance of these components ensures that your device works smoothly without any interruptions or power issues.

-

Sensors: In devices like Shelly’s thermostat, sensors are key for detecting the environment around them. For instance, the thermostat needs to measure the temperature in the room to adjust settings automatically. These sensors send this real-time data to the MCU for processing.

-

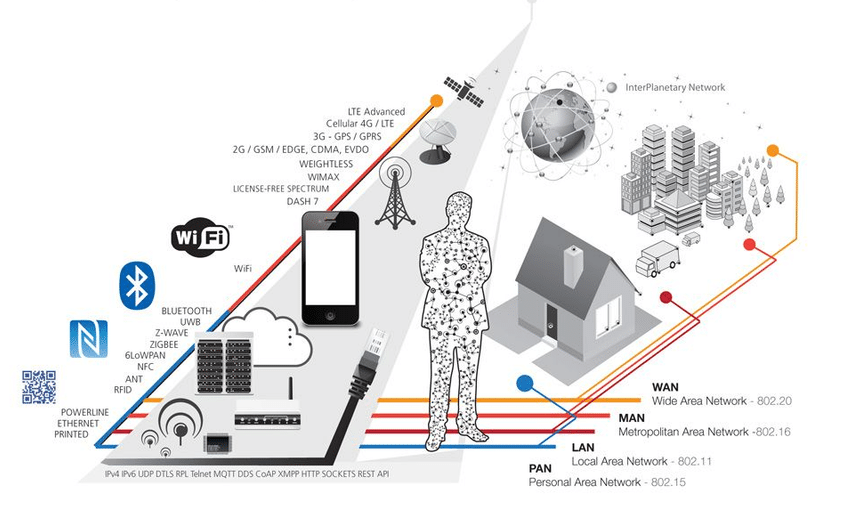

Connectors and Antennas: IoT devices rely heavily on wireless communication. Connectors and antennas embedded in the PCB are responsible for connecting your device to a larger network, whether it’s Wi-Fi, Bluetooth, or Zigbee.

Each component must be carefully chosen and precisely integrated. When designing and assembling the PCB for an IoT device, the quality of each part impacts the device’s performance. So, having a reliable PCB assembly partner becomes crucial, especially when producing high-volume products like Shelly’s smart devices.

When designing PCBs for IoT devices, hands-on experience and the right educational resources are invaluable. For example, HCPS Laboratory’s IoT Device Design course at FIU provides in-depth knowledge of hardware design using PCB software like Eagle.

What is PCB Assembly Equipment?

PCB assembly isn’t just about the components – the equipment used in the assembly process is just as important. To ensure accuracy, speed, and quality, you need specialized machinery.

Here are the key pieces of equipment used in PCB assembly:

-

Solder Paste Printing Machine: This machine applies a thin layer of solder paste onto the PCB pads, ensuring that the components will be correctly soldered in the next step.

-

Pick-and-Place Machine: This high-tech machine places the components onto the PCB with precision, ensuring that they are aligned perfectly for optimal functionality.

-

Reflow Oven: After the components are placed, the PCB moves through a reflow oven. This oven heats the PCB to melt the solder paste, permanently attaching the components to the board.

Using advanced equipment ensures a consistent, high-quality assembly process, reducing the chances of human error and allowing for faster production times, which is essential for scaling production and meeting the needs of clients like Shelly.

PCB assembly requires an understanding of both theory and practice, such as the special topics in circuits at Carnegie Mellon, where students learn about assembly techniques and board-level RF systems.

Why is Selecting the Right PCB Assembly Partner Important for IoT Products?

When developing high-quality IoT products, like Shelly’s smart thermostatic radiator valve, choosing the right PCB assembly partner can make all the difference. Here’s why:

-

Expertise in High-Volume Production: As your product grows, so does your production scale. A trusted assembly partner will be experienced in handling high-volume production runs while ensuring that quality is never compromised. This is especially important for IoT products where reliability is non-negotiable.

-

Advanced Quality Control: The complexity of IoT devices means that every component has to function together seamlessly. A reliable PCB assembly partner will have rigorous testing and quality assurance processes in place to ensure that each board meets industry standards.

-

Faster Time-to-Market: In a fast-moving market, speed is critical. Working with an experienced assembly service ensures faster turnaround times, allowing you to get your IoT products into the hands of customers more quickly.

Partnering with the right PCB assembly company is an investment that pays off in the long run. By ensuring top-notch quality and fast production, you can focus on what matters most: scaling your IoT product line and satisfying your customers.

For more detailed information on the fundamentals of PCB prototyping and manufacturing, check out Fischer Engineering Design Center’s PCB FAQ, which addresses common questions about circuit board design.

How Do PCBs Enable Connectivity in IoT Devices?

Connectivity is a hallmark of any IoT device, and it all starts with the PCB. Shelly’s smart thermostatic radiator valve, for example, uses a PCB to integrate wireless communication modules like Wi-Fi and Bluetooth, allowing it to communicate with other devices in the home automation system.

Here’s how it works:

- The PCB houses the antenna and communication module that allows the thermostat to connect to your home network.

- The microcontroller (MCU) processes the data from the sensor, adjusts settings, and sends this information via the communication module to the app or cloud server for remote monitoring and control.

Without a high-quality PCB, the connectivity aspect of an IoT device wouldn’t be as seamless or reliable. For devices that need to interact with a larger system, like Shelly’s, the PCB ensures that communication is quick and reliable, with minimal interference.

Understanding the layers and functions of PCBs is essential for creating reliable IoT devices. A detailed explanation of Printed Circuit Boards and their Layers can help clarify these components.

How Do PCBs Impact the Performance of Smart Devices Like Shelly’s Thermostat?

The quality of the PCB is directly tied to the performance of the device. For Shelly’s smart thermostatic radiator valve, the PCB ensures:

- Signal Integrity: A well-designed PCB minimizes signal loss and ensures that the communication between components (like sensors, MCU, and wireless modules) is stable.

- Power Management: IoT devices are power-hungry, and the PCB ensures that the device uses energy efficiently. Without proper power distribution, devices can become unstable or even fail prematurely.

- Thermal Management: Excessive heat can degrade performance. Proper heat dissipation integrated into the PCB ensures that the components don’t overheat, which is crucial for the longevity of devices like smart thermostats.

In short, the PCB impacts every part of your device’s performance. A high-quality PCB ensures that your IoT devices run smoothly, efficiently, and reliably, meeting both customer expectations and industry standards.

What Are the Challenges in Developing High-Volume IoT Products and How Can PCB Assembly Help?

Developing high-volume IoT products like Shelly’s smart thermostatic radiator valve is not without its challenges. Here’s a quick breakdown of the most common ones:

- Complex Designs: IoT devices combine multiple functions, such as temperature sensing and wireless communication, which makes PCB design more complex.

- Scaling Production: As demand for your product increases, so does the need for larger production runs. Keeping the quality consistent and the costs low is a challenge.

- Component Sourcing: Sourcing the right components, especially in large quantities, can be tricky. Ensuring component availability while meeting quality requirements is vital for maintaining production timelines.

A trusted PCB assembly partner helps mitigate these challenges by ensuring consistent quality, timely delivery, and effective scaling, helping you to meet the needs of high-volume production without sacrificing performance.

FAQs

When selecting a PCB assembly partner, look for one with experience in high-volume production, strong quality control processes, and the ability to meet rigorous testing requirements. It’s also important that they offer quick turnaround times to keep up with market demand.

Yes, optimizing the PCB design for thermal management and power distribution can greatly enhance the longevity of IoT devices. Proper design ensures that components do not overheat or suffer from power surges, which can extend the lifespan of your product.

Common issues include poor signal integrity, inadequate thermal management, and improper power distribution. These can lead to device malfunction, poor connectivity, and shortened lifespan. Working with an experienced PCB assembly partner can minimize these risks.

Testing the design with prototyping and making necessary adjustments based on feedback can ensure your PCB is production-ready. Additionally, a reliable partner can help with scalability, ensuring that your design works just as well in large batches.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

In conclusion, selecting the right PCB components and assembly partner is crucial for producing reliable, high-performance IoT devices like Shelly’s smart thermostatic radiator valve. By focusing on the key elements—microcontrollers, SoCs, and connectivity—and partnering with an experienced PCB assembly company, you can ensure that your IoT products meet the highest standards for smart home automation.

If you’re looking for a reliable partner to handle your PCB assembly needs for IoT products, contact us today to learn more about our services and how we can help bring your vision to life.

Have Specific Requirements?

We’re here to help! Whether it’s a custom PCB design, assembly, or sourcing components, feel free to reach out to us directly. Our team is ready to provide tailored solutions for your project. Contact Us Today for more information.Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!