Quick Leads-PCBA

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Tired of production delays caused by file issues? Many engineers underestimate how critical precise Gerber and BOM files are for streamlined SMT PCB assembly. Miscommunication leads to rework, delays, and rising costs. In this guide, I’ll show you exactly how to avoid that—whether you’re ordering one board or a thousand.

To prepare Gerber and BOM files for error-free PCB assembly with no MOQ, ensure all fabrication layers are correctly outputted (copper, silkscreen, solder mask, drill files), align file names per IPC-2581 standards, and include a detailed BOM with component values, part numbers, and polarity. Verify files using a Gerber viewer and request a Design for Manufacturing (DFM) check for added precision. This prevents SMT errors and ensures faster assembly even in small batches.

Let’s explore what makes file preparation such a bottleneck—and how your process can be optimized from the start to avoid costly missteps during manufacturing and assembly.

To avoid quotation delays and component mismatch, we recommend using a standardized PCB assembly BOM template.

Why Accurate File Preparation Matters in Turnkey PCB Assembly

When outsourcing to a turnkey PCB assembly service, your Gerber and BOM files become the entire foundation of communication. But precision is often overlooked.

Pain Points in the Industry:

| Problem | Consequence | Engineer’s Concern |

|---|---|---|

| Incomplete files | Delays, rework | “Will it delay production?” |

| Wrong format | File rejection | “Will they even accept this format?” |

| Missing polarity info | Faulty assembly | “I can’t afford reassembly.” |

In a turnkey PCB assembly service in China, manufacturers must quickly interpret files, source parts, program machines, and initiate soldering—all from your documentation. That’s why a single omission can halt everything.

At our facility, we include component sourcing service, AOI inspection, and functional testing for PCB to catch errors before they cost you.

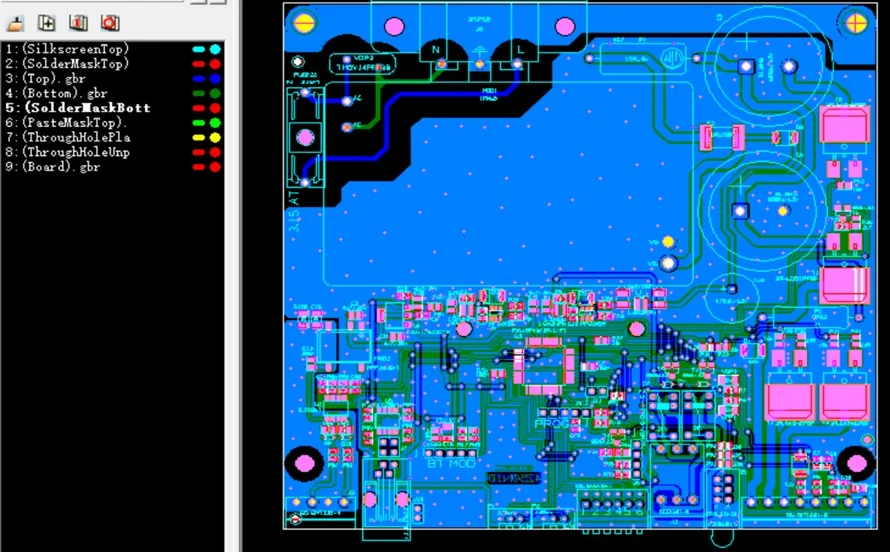

Common Mistakes When Creating a Gerber File for PCB

Gerber files are the manufacturing blueprints. But common oversights cause assembly failure or fabrication rejection.

🛑 Common Mistakes:

-

Missing or misaligned drill files

-

Incorrect file naming (non-standard)

-

No board outline or solder mask layers

-

Files exported with wrong units or offsets

-

No preview check using a Gerber file viewer

Here’s how to generate Gerber files correctly:

-

Finalize your PCB layout (double-check DRC errors)

-

Use your CAD tool’s “Export Gerber” feature

-

Select essential layers: top/bottom copper, silkscreen, solder mask, drill files

-

Include board outline as a separate layer

-

Export using RS-274X format (avoid obsolete RS-274D)

-

Name files clearly:

.GTL,.GBL,.GTS, etc. -

Preview using a free tool like Gerbv or ViewMate

✅ Tip: Add README or manifest file listing file names and layer functions.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

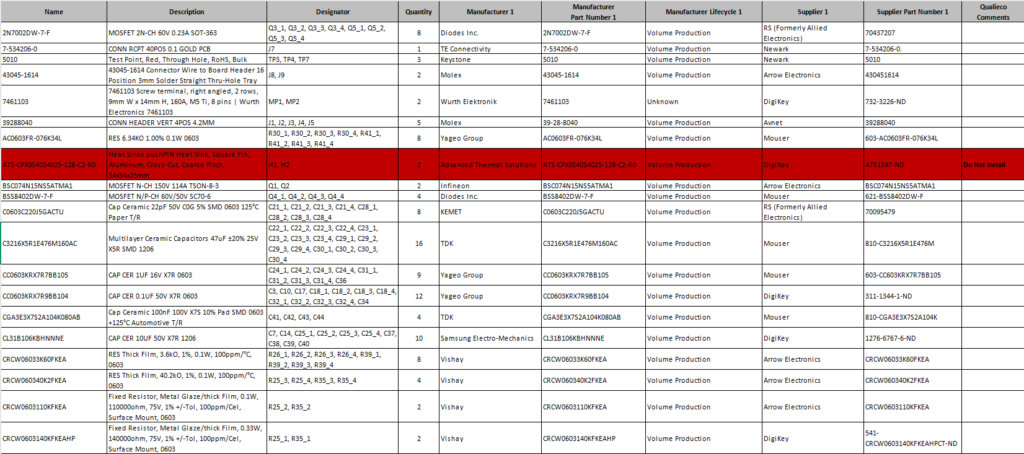

BOM File Explained: What Manufacturers Really Need

A Bill of Materials (BOM) is not just a spreadsheet—it’s your assembly playbook.

Yet, many BOMs arrive half-complete, with vague part numbers or missing designators. That creates confusion during pick-and-place, slows down sourcing, and increases the risk of incorrect component placement.

What to Include in a BOM:

-

Reference Designators (R1, C2, U3…)

-

Quantity

-

Component Values (e.g., 10kΩ, 0.1μF)

-

Footprint or Package (0603, SOIC-8, etc.)

-

Manufacturer Part Number (MPN)

-

Supplier Part Number (SPN) or SKU

-

Polarity Indication (for diodes, ICs, etc.)

-

Notes (e.g., “Do Not Place” or alternates)

💡 We offer a free BOM template with auto-check for polarity and part number validation. Ask our engineers during your upload process. For step-by-step instructions on generating a BOM in Altium, refer to Altium’s BOM creation guide.

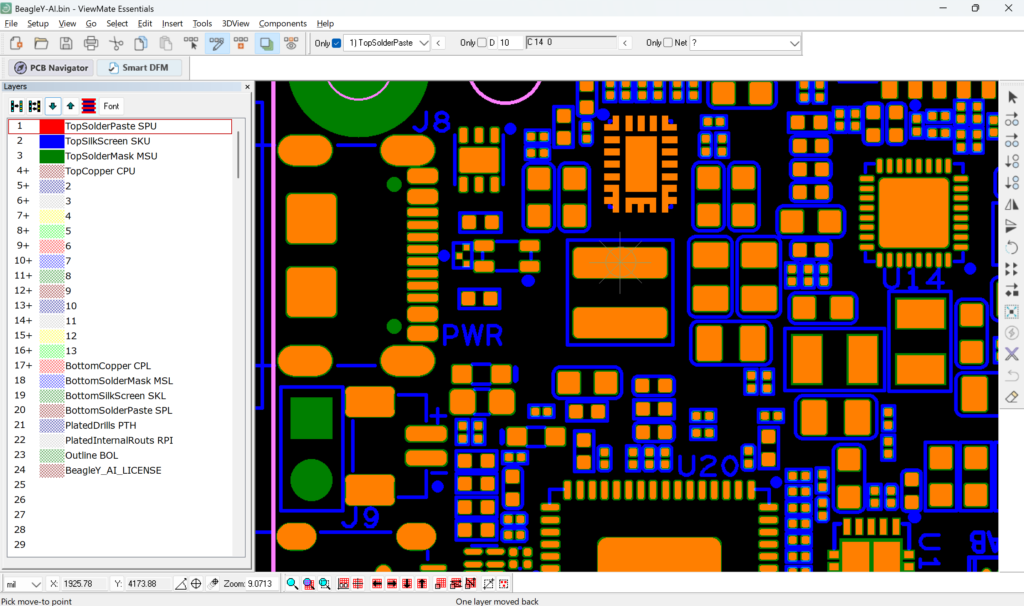

How to Verify Gerber Files Before Uploading

Once you’ve exported your files, don’t blindly send them. Verifying Gerber files ensures that what you see is what the factory builds.

What to Check:

-

Layer alignment (copper vs. silkscreen vs. solder mask)

-

Board outline accuracy

-

Via holes and drill files match pads

-

Silkscreen doesn’t overlap pads

-

Polarity marks for ICs, LEDs, diodes

Use These Free Gerber Viewers:

✅ Bonus: Our DFM team will re-check uploaded files using industrial-grade viewers and offer free corrections or suggestions if needed. If you’re new to Gerber viewers, here’s a beginner’s guide on how to open Gerber files using free tools like Gerbv or ViewMate.

SMT PCB Assembly Challenges and How to Solve Them

SMT PCB Assembly no MOQ services open the door for fast prototyping—but bring challenges too.

Key Technical Issues in SMT Assembly:

| Issue | Cause | Prevention |

|---|---|---|

| Tombstoning | Uneven pad heat | Panelization + thermal balancing |

| Solder bridging | Excess paste or spacing | Correct stencil thickness |

| Offset placement | Bad centroid file | Accurate pick-and-place data |

| Cold solder joints | Reflow misprofile | Controlled reflow soldering |

| Component polarity error | Poor silkscreen or missing BOM info | Add pin 1 indicators & BOM clarity |

We apply AOI inspection and reflow soldering temperature profiling per IPC-A-610 standards—essential for clean, repeatable assembly.

Our inspection process aligns with UL’s PCB compliance and reliability standards to ensure consistent solder quality and functional integrity.

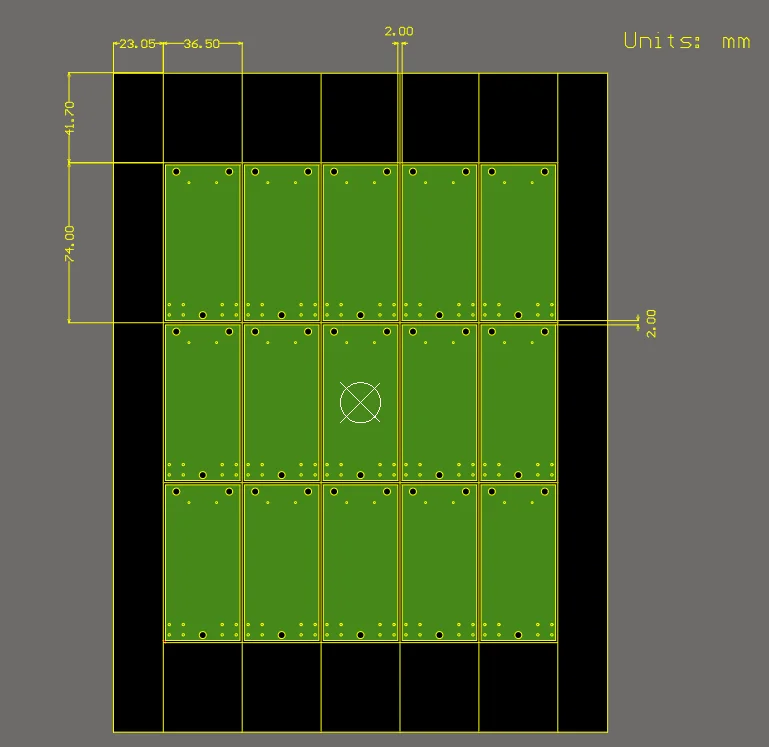

Why Panelisation is the Hidden Secret to Efficiency

Panelization isn’t just for large orders. It’s essential for small batch PCB assembly with testing and no MOQ orders.

Benefits of Panelization:

-

Faster machine setup

-

Reduced handling damage

-

Lower cost per unit

-

Easier AOI and functional testing

-

Better alignment for stencil printing

Even for 5–10 PCBs, a well-designed panel can cut your lead time in half.

🔧 Need help? We offer complimentary panelization with recommendations for breakaway tabs, tooling holes, and fiducials based on your project type. For a deeper dive into how panelization impacts assembly speed and cost, check out our guide on why PCB panelization is essential for efficient assembly.

From Gerber to Quote: Upload for Fast DFM Review & PCB Quote

Want a quote in less than 24 hours?

Just upload your Gerber and BOM files for an instant PCB quote. Our platform supports:

-

Zip file uploads of all Gerber layers

-

BOM import with MPN mapping

-

Free DFM review + file verification

-

Feedback in <24 hours—even on weekends

👨🏭 No back-and-forth emails. No missed deadlines. Just upload, and we’ll do the rest.

Our One-Stop, No-MOQ PCB Assembly Service

Whether you’re a hardware startup or an R&D department, our no MOQ PCB assembly service is designed for flexibility and speed.

Why Engineers Choose Us:

-

China-based turnkey PCB assembly with global logistics

-

One-stop solution: fab, source, assemble, test

-

Small batches welcome—even single units

-

DFM, BOM, and stencil review included

-

Fast-track production for urgent projects

🛠️ Perfect for: Hardware prototypes, pilot runs, or low-volume commercial launches.

FAQs

1. Can I use my existing Gerber files for your turnkey PCB assembly service in China?

Yes, as long as your Gerber files include all standard layers (copper, silkscreen, solder mask, and drill), we can accept them. Our turnkey PCB assembly service in China includes a free DFM check to ensure file compatibility. If we spot issues or missing layers, we’ll notify you and help fix them—fast, without extra cost.

2. What if my BOM file doesn’t include manufacturer part numbers (MPNs)?

No problem. If your BOM lacks MPNs, our BOM analysis and component sourcing service can help match parts based on descriptions and footprints. However, we recommend including MPNs to speed up sourcing and avoid substitutions. Upload your BOM, and we’ll assist in validating or completing it—especially useful for small batch PCB assembly with testing needs.

3. Is it possible to get a PCB quote without uploading a Gerber file?

We understand that sometimes your files aren't finalized yet. While we can provide a rough estimate based on specifications, to receive an instant PCB quote and accurate lead time, we need both Gerber and BOM files. Uploading both ensures your SMT PCB assembly no MOQ order can be reviewed and quoted within 24 hours.

4. Do I need to panelize my PCB before ordering?

No—panelization is not required before ordering. In fact, we offer complimentary panelization recommendations to optimize for stencil printing, reflow soldering, and AOI inspection. Especially for no MOQ PCB assembly, our engineers will suggest the most efficient layout for small runs. Just upload your single-board design—we’ll handle the rest.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Upload Your Files and Start Assembling Smarter

Preparing accurate Gerber and BOM files is the foundation of successful PCB manufacturing. With our one-stop, no-MOQ turnkey solution, you’ll avoid delays, reduce costs, and ship faster.

📩 Upload your files today for a free review and panelisation suggestion—no commitment, just results.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!