Quick Leads

What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Introduction

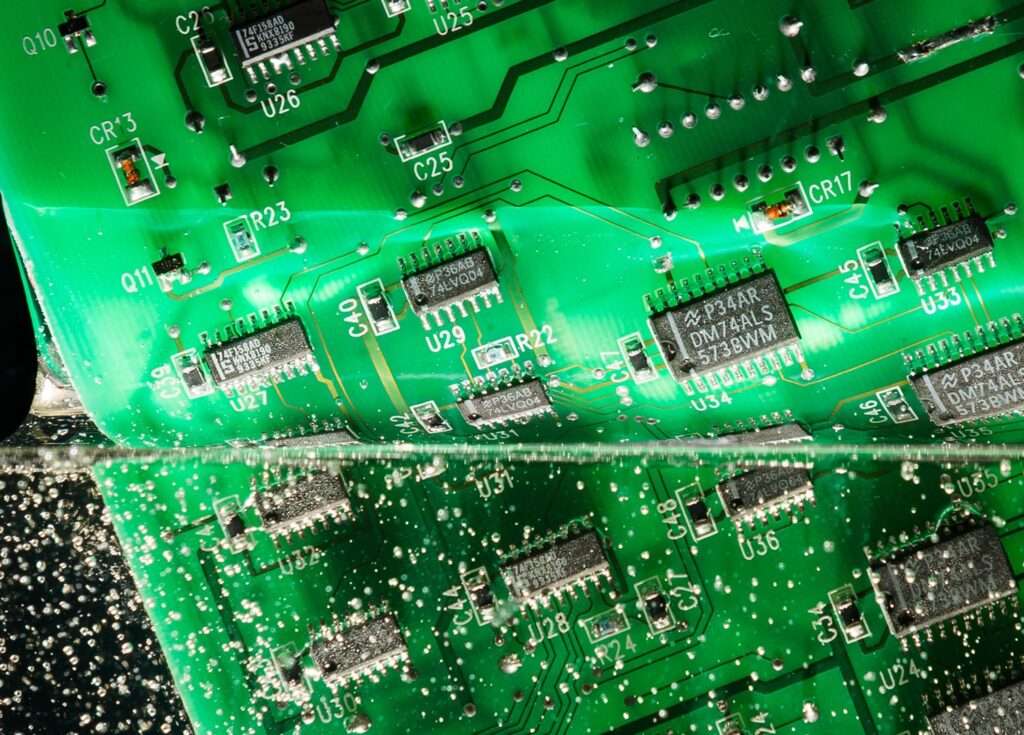

Conformal coatings protect printed circuit boards (PCBs) from environmental damage. They protect PCBs from moisture, dust, and extreme temperatures. They help PCBs last longer and work better in tough conditions. In this guide, I’ll cover the basics of PCB conformal coatings, including the different types, the benefits, and the uses.

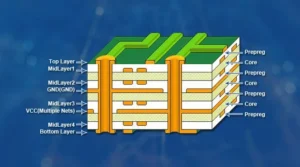

Understanding Conformal Coating in PCB

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Why Conformal Coating Is Essential for PCB Durability

- Protection from Moisture and Contaminants: They keep water, dust, and chemicals away from the PCB, which prevents corrosion.

- Acts as an Insulating Layer: This stops short circuits between components.

- Extends Lifespan: Coatings reduce the need for maintenance and help PCBs last longer, saving costs over time.

Top Applications of Conformal Coatings Across Industries

- Automotive Electronics: Keeps PCBs in engine control units safe from heat and vibrations.

- Aerospace and Defense: Ensures PCBs in aircraft and satellites work well in extreme conditions.

- Medical Devices: Protects moisture-sensitive devices like pacemakers.

- Consumer Electronics: Helps smartphones and wearables resist humidity.

- Industrial Electronics: Shields factory automation systems from dust and chemicals.

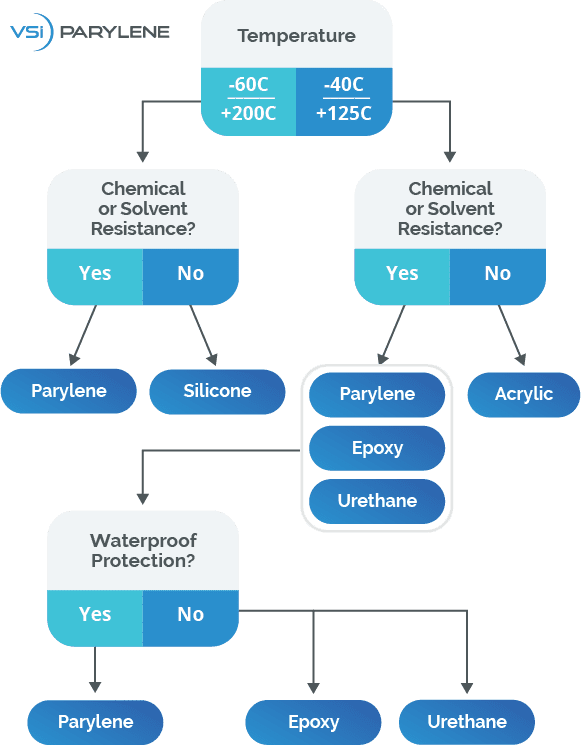

A Comparison of Different Conformal Coating Types

- Parylene: Excellent at blocking moisture. It’s ideal for medical devices and aerospace electronics.

- Acrylic Resin: Affordable and easy to use. Great for general electronics.

- Urethane (Polyurethane): Resists chemicals well. It’s best for automotive and industrial use.

- Silicone: Stays flexible and handles heat. It’s perfect for high-temperature settings.

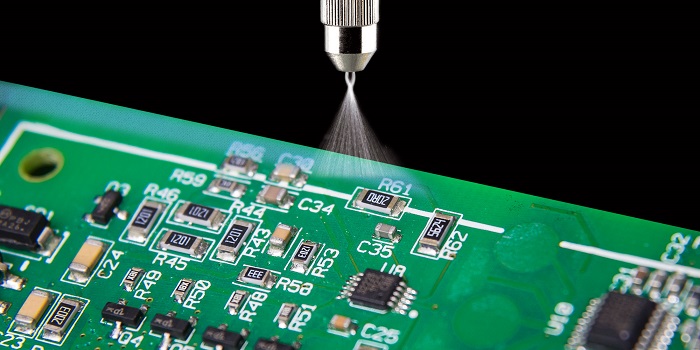

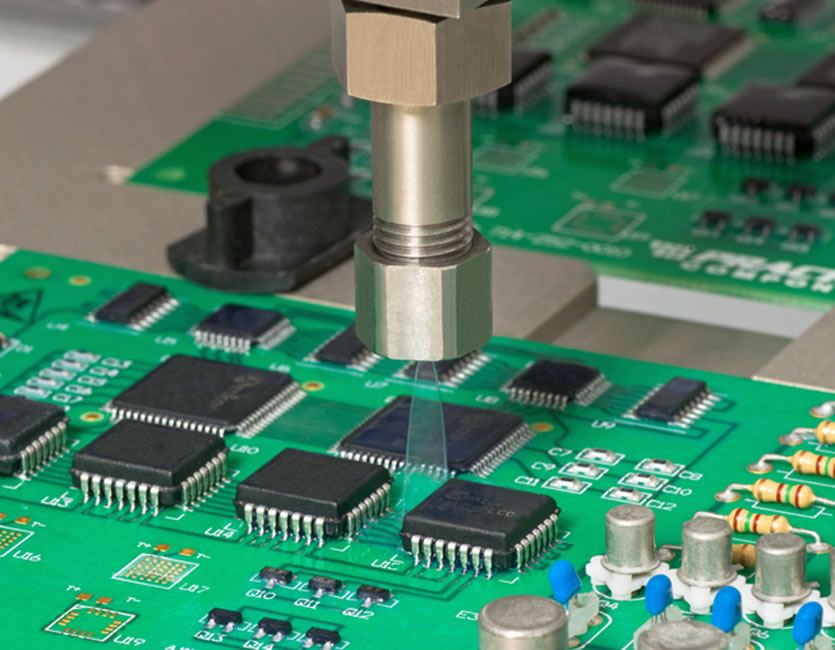

How to Apply Conformal Coating on PCB

- Brushing: Best for small areas and simple fixes.

- Spraying: Covers surfaces evenly. Ideal for medium-sized projects.

- Dipping: Ensures even coverage. Works well for large-scale manufacturing.

- Selective Coating: Uses machines to apply coating only where needed, saving material.

Does Conformal Coating Affect PCB Heat Dissipation?

How Do You Repair Damaged Conformal Coatings?

Benefits of PCB Conformal Coatings

-

Shields against moisture, dust, and contaminants

-

Provides insulation to stop short circuits

-

Extends the lifespan of electronics, reducing maintenance

Frequently Asked Questions (FAQ)

Conformal coatings protect printed circuit boards (PCBs) from things like moisture, dust, and chemicals that can cause damage. They also help prevent short circuits, making the electronic components last longer and work better, even in tough environments.

Choosing the right coating depends on where the PCB will be used. For example, parylene is great for delicate devices like medical equipment, while silicone is better for places with high temperatures. Think about things like temperature and exposure to chemicals when deciding.

Yes, you can remove conformal coatings, but the method depends on the type. Acrylic coatings can be removed with special solvents, while silicone might need scraping or special removers. Be careful to avoid damaging the PCB when removing the coating.

Conformal coatings usually don’t change how a PCB works if applied properly. But if you put on too much, it might slightly impact high-frequency signals. Following the guidelines for how thick to apply the coating can help avoid any issues.

Quick Summary

- Conformal coatings protect PCBs against moisture, dust, and chemicals.

- They are widely used in automotive, aerospace, medical, and industrial electronics.

- Choosing the right type of coating depends on the environment and needs.

- Coatings can be applied through methods like spraying, dipping, and brushing.

- Proper application ensures protection without compromising performance.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!