Quick Leads

Decoding PCB: What PCB Stands for in Electronics & How to Source from China

Learn what a PCB (Printed Circuit Board) is, its types and functions, and expert tips on sourcing high-quality PCBs from China for electronics manufacturing.

Introduction

What is a PCB? (Definition and Function)

How Does a PCB Work?

Types of PCBs (with Applications)

PCB Type | Key Features | Common Applications |

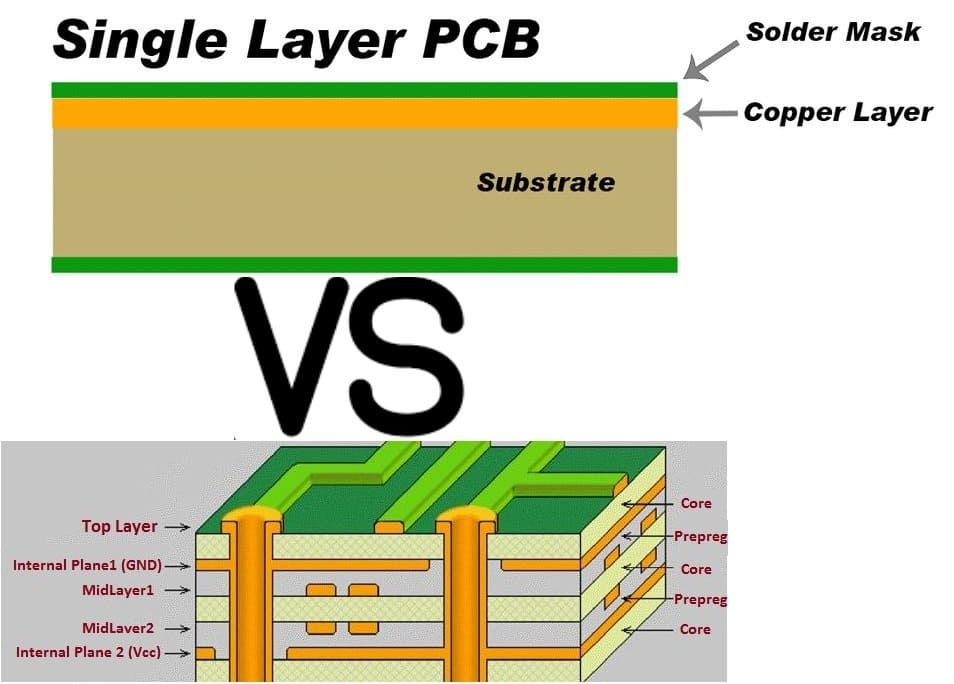

Single-Layer PCB | Single copper layer; basic and cost-effective | Simple devices like remote controls, calculators |

Double-Layer PCB | Copper on both sides for more connections | Lighting systems, amplifiers |

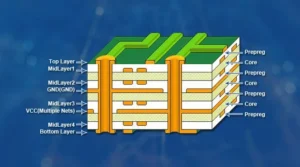

Multi-Layer PCB | Multiple layers for advanced circuits | Computers, smartphones |

Flexible PCB | Can bend to fit tight spaces | Wearables, medical devices |

Rigid-Flex PCB | Combines flexibility and durability | Mobile devices, medical equipment |

Rigid PCB | Stable, durable structure | Automotive, industrial machinery |

What are the Main Components of a PCB?

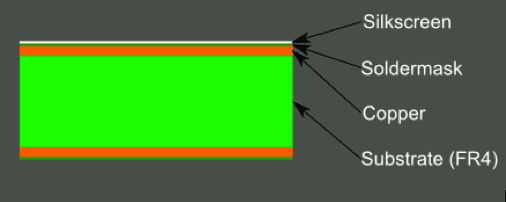

- Substrate: The base material that affects the board’s strength and heat resistance. Higher-quality substrates can handle more heat and pressure.

- Copper Layer: The thickness of this conductive layer affects how much power the board can handle. Make sure your supplier meets your device’s power needs with the right copper specifications.

- Solder Mask: The insulating layer that keeps you from accidentally shorting things out. You need a good solder mask, especially if you’re making complex or high-voltage devices.

- Silkscreen: This labeling layer helps you identify parts for assembly and repair. Some suppliers will let you customize your silkscreen so you can troubleshoot easily.

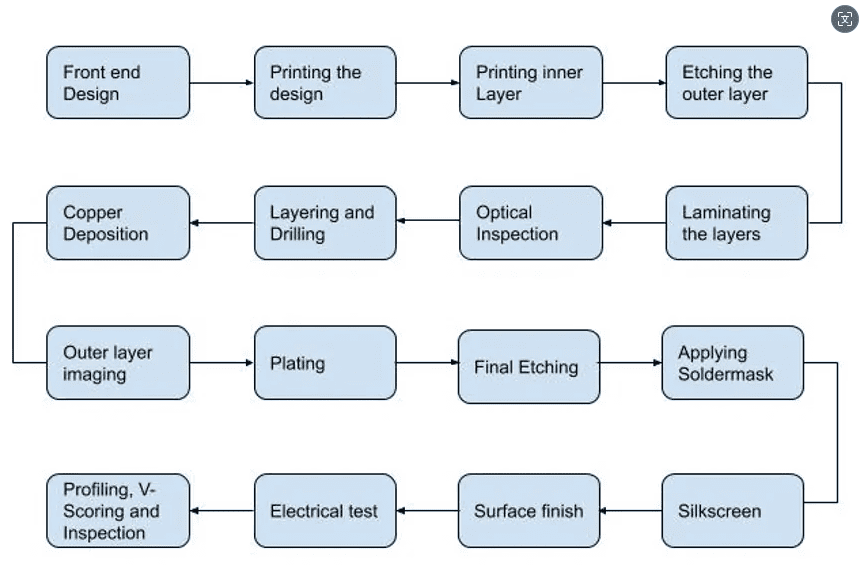

How are PCBs Manufactured?

- Design and Etching: They etch your design onto copper. Make sure your supplier can customize designs to your specifications.

- Layering and Drilling: They stack up layers and drill holes in just the right places so you can connect all your components.

- Solder Mask and Silkscreen Application:They put on insulation and labels to make it easier to put everything together and keep you from shorting things out.

- Quality Checks: Make sure your supplier does quality control stuff like Automated Optical Inspection (AOI) and Functional Testing to catch problems before they ship your boards.

Applications of PCBs in Different Sectors

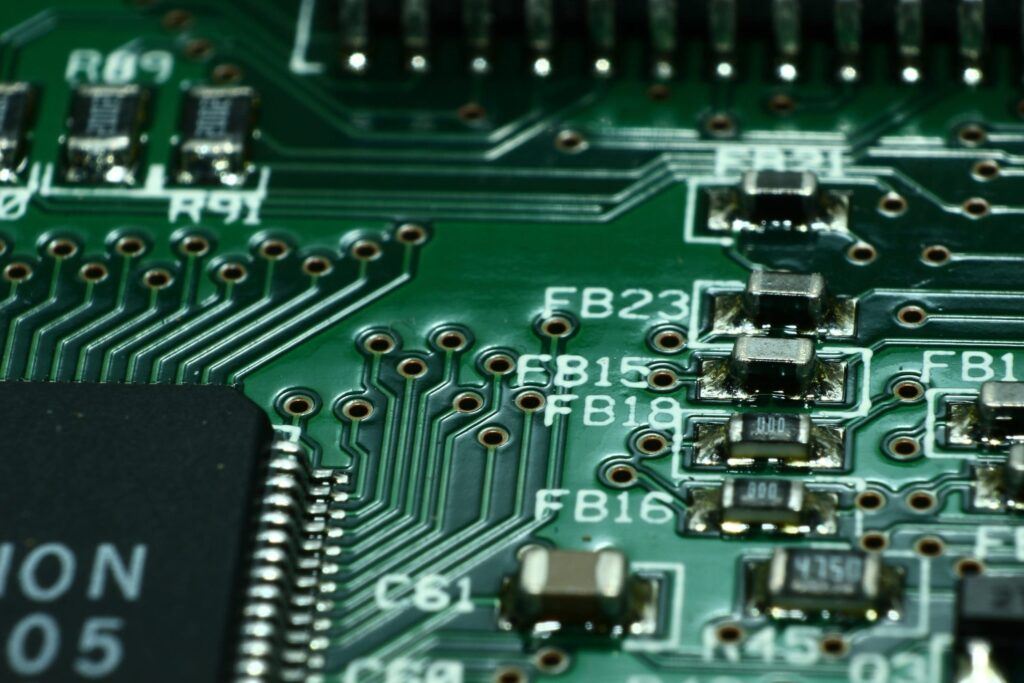

- Consumer Electronics: PCBs are in all kinds of consumer products like PCs, TVs, and smartphones. When you’re making these, you care about how they look, how long they last, and how much they cost.

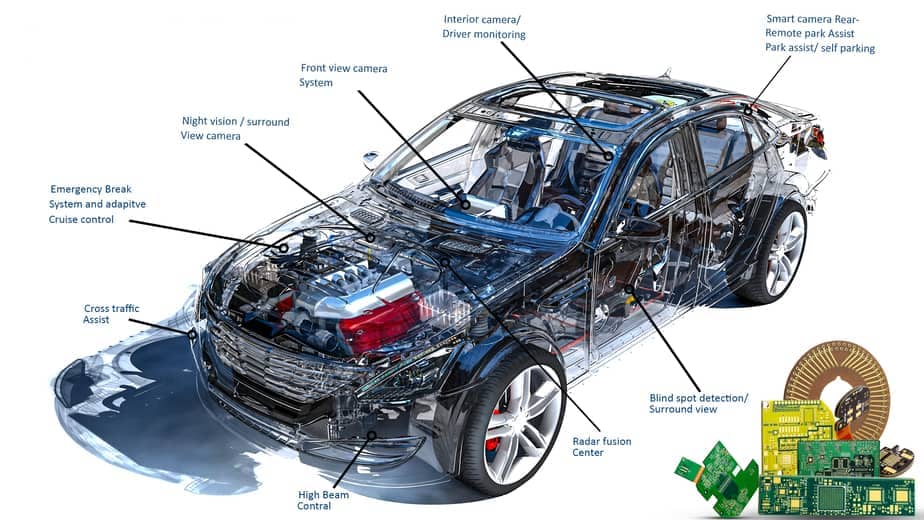

- Automotive and Industrial Machinery: These applications need PCBs that can handle high heat and pressure. Look for suppliers who have experience making automotive-grade PCBs.

- Medical Devices: These applications need little tiny PCBs that have to be perfect. Make sure your supplier can give you certification like ISO 13485 for medical devices.

Advantages of Using PCBs (and Sourcing Them from China)

- Certifications: Reliable suppliers have ISO 9001 or RoHS certifications, indicating quality and environmental compliance.

- Experienced Suppliers: Established manufacturers with a track record can offer valuable insights and ensure consistent quality.

Tips for Importing PCBs from China

- Research Suppliers: Look for positive reviews, certifications, and industry experience to make sure a supplier is legit.

- Request Samples: Testing sample boards can reveal quality firsthand, allowing you to make informed decisions.

- Compliance and Shipping: Ensure your supplier complies with international standards and handles shipping efficiently to avoid delays.

- Negotiate Pricing: While pricing is competitive, prioritize value. Bulk discounts are common, but quality should be your first concern.

- Build Relationships: A strong relationship with a supplier can lead to better service, customized options, and competitive pricing.

For more information, visit below:

Frequently Asked Questions (FAQ)

PCB stands for Printed Circuit Board. It provides a platform for electronic components and conductive pathways, essential in nearly all modern electronics.

The process includes designing, etching, layering, drilling, and testing for quality assurance. Understanding these steps can help importers evaluate suppliers.

Consider the application, such as whether your product requires durability (rigid PCBs), flexibility (flexible PCBs), or complexity (multi-layer PCBs).

Certifications like ISO 9001 for quality management, RoHS for environmental compliance, and industry-specific standards (e.g., ISO 13485 for medical devices) are essential.

Don’t work with suppliers who don’t have the right certifications, skip quality checks, or don’t test samples. Make sure they can ship your stuff and talk to you.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!