Quick Leads

How Do PCBs Differ from Printed Wiring Boards?

What Sets PCBs Apart from PWBs?

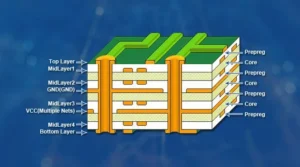

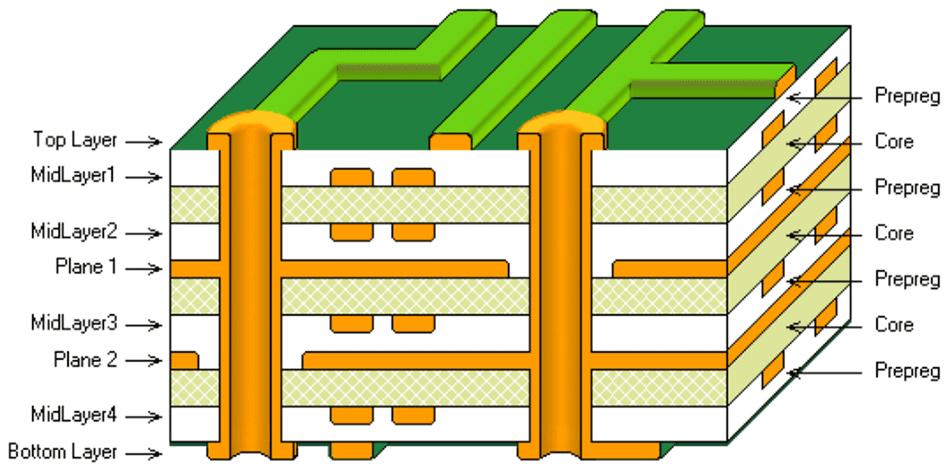

Structural Design

-

Key snippet: Construction differences: PCBs are rigid or flexible boards made of insulating materials with copper traces.

-

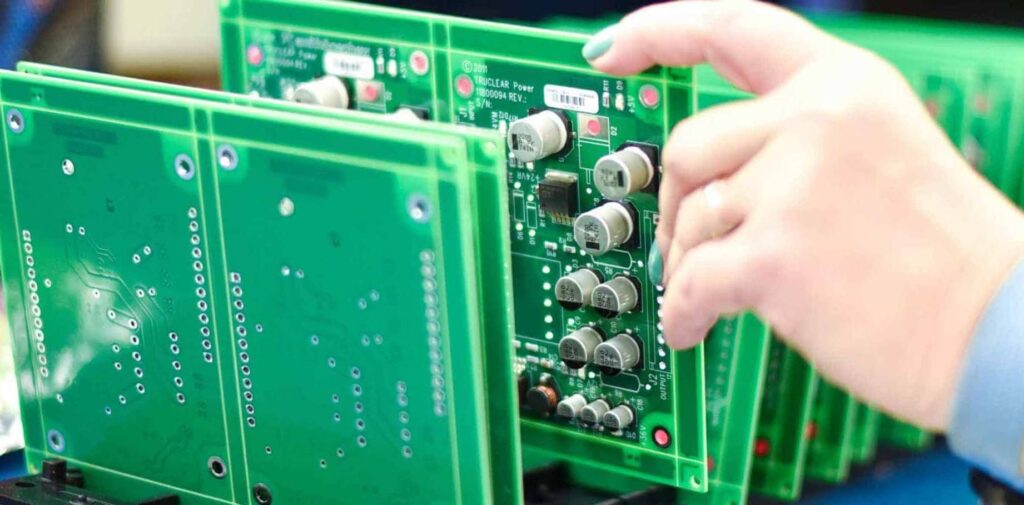

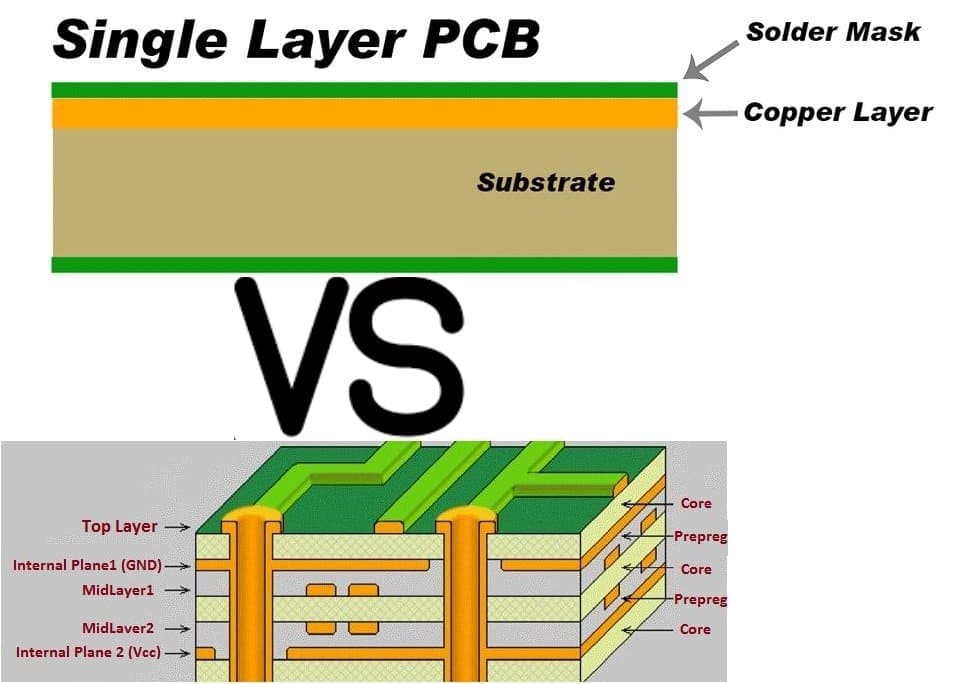

PCBs are made of insulating materials such as fiberglass or epoxy, layered with conductive copper traces. This structure enables PCBs to handle complex circuits in a variety of configurations, whether rigid or flexible.

-

PWBs are typically single-sided and lack the multi-layered insulation of PCBs. While they offer a simpler structure, PWBs are less versatile, making them ideal for straightforward applications that don’t require complex circuitry.

Complexity

The complexity of PCBs and PWBs affects their application. PWBs are suitable for low-complexity electronics, featuring basic layouts ideal for simple devices.

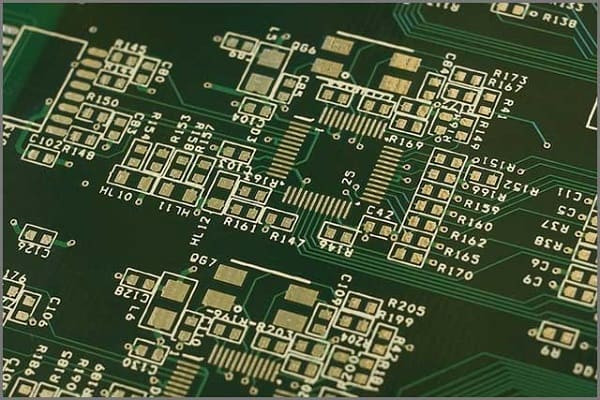

In contrast, PCBs support advanced electronics with their multi-layered design, allowing them to handle intricate circuits in fields like aerospace, medical, and high-performance consumer electronics.

Performance

-

Key snippet: PCBs are usually for one thing, while motherboards are modular and connect to other boards.

-

PCBs are specialized for specific applications, providing effective solutions for targeted roles. For example, motherboards connect multiple PCBs and other components, creating a modular design with flexibility.

-

PCBs’ versatility makes them ideal for high-performance applications that demand stability and functionality. PWBs, on the other hand, are best suited for simpler, static circuits.

Manufacturing Processes

-

Key snippet: A printed circuit board (PCB) is non-conductive with conductive lines for connecting components, while a PCBA is a board that has been assembled.

-

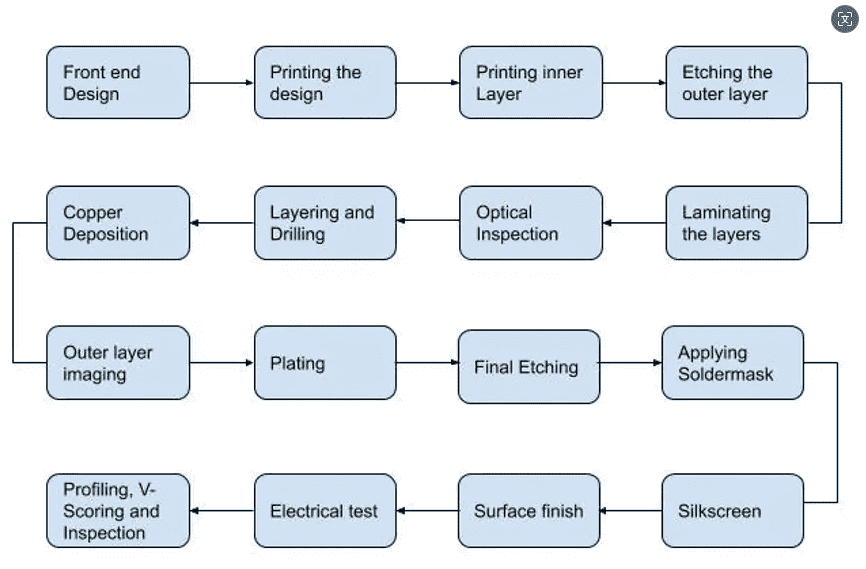

PCB Manufacturing: PCBs involve complex, layered assembly, often requiring laminations for high-density circuits. This is necessary for advanced electronics.

-

PWB Manufacturing: PWBs go through a simpler process, typically a single conductive layer etching. Unlike PCBs, a PCBA (Printed Circuit Board Assembly) is a completed board with all components attached, ready for functional use.

Cost

- Key snippet: A PCB is a blank board without components, whereas a PCBA is a fully assembled board ready to go.

- PWBs are cheaper because they’re simpler. They’re single-sided and basic, which makes them good for low-cost applications.

- PCBs, on the other hand, are more expensive because they’re multi-layered and require more manufacturing steps. PCBs are bare boards, while PCBAs are assembled, working boards with all the components. That extra assembly adds cost

Comparison Table: PCB vs. PWB

|

Feature |

PCB (Printed Circuit Board) |

PWB (Printed Wiring Board) |

|

Design |

Rigid or flexible, multi-layer, with copper traces |

Typically single-sided and basic structure |

|

Complexity |

Supports high-density circuits, suitable for complex devices |

Low complexity, ideal for simple devices |

|

Performance |

Used in high-performance applications |

Suited for basic, low-performance electronics |

|

Manufacturing |

Involves multi-layer lamination and advanced assembly |

Basic etching of a single conductive layer |

|

Cost |

Higher cost due to complexity and materials |

More budget-friendly for basic electronics |

For more information, visit below:

Frequently Asked Questions (FAQ)

PWBs are generally not suitable for high-performance applications due to their simpler, single-layer design. They are best for straightforward electronics that don’t require complex circuitry.

PWBs are more affordable because of their basic construction, while PCBs involve additional costs due to multi-layering and intricate manufacturing processes. PCBAs, with all components assembled, incur even higher costs.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

Understanding the difference between PCBs and Printed Wiring Boards allows professionals to make better decisions in electronics manufacturing. PWBs are a low-cost option for simple circuits. PCBs are tough, flexible, and necessary for high-complexity, high-performance applications. Knowing the difference helps engineers, designers, and buyers get the best balance of cost and performance.RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select the right transformer for SMPS, IoT, or relay control. Start designing smarter today.

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and delivery—and how turnkey EMS solutions protect your product and bottom line.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!