Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Hardware development timelines keep shrinking. At the same time, PCB designs are getting more complex, component availability is less predictable, and assembly tolerances are tighter than ever. For engineers and sourcing decision-makers, the real challenge is no longer just speed—it’s delivering working boards fast, without introducing hidden risks.

Quick turn turnkey PCB assembly exists to solve this problem. But not all “turnkey” services are created equal. Some accelerate development. Others quietly introduce failure points that only surface after boards arrive—or worse, during field testing.

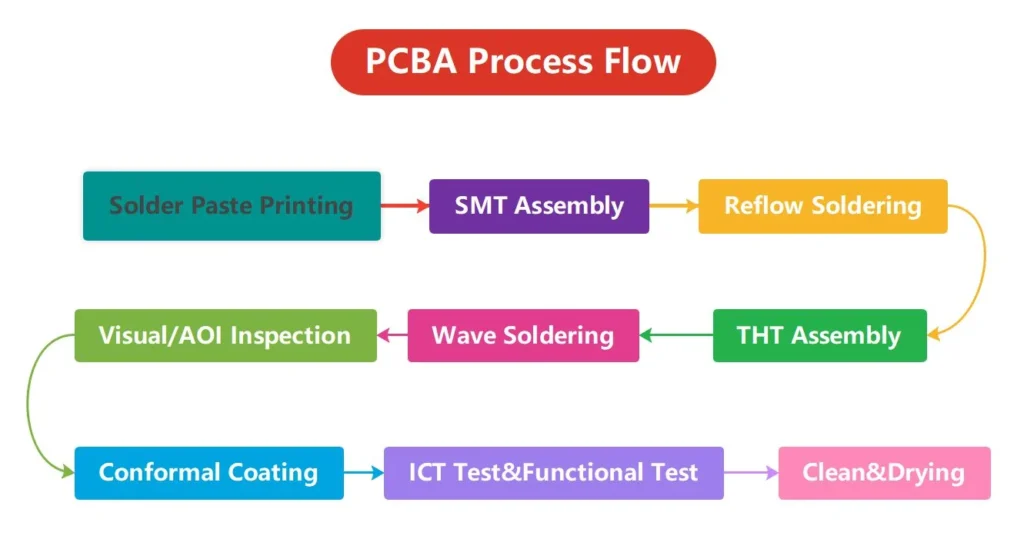

Quick turn turnkey PCB assembly is a fully managed manufacturing service that combines PCB fabrication, component sourcing, SMT and through-hole assembly, and testing to deliver functional circuit boards in days instead of weeks, while reducing sourcing errors, soldering defects, and yield risk. Unlike low-cost assembly platforms, true turnkey services emphasize engineering control, DFM/DFA review, and verification at every stage.

Speed alone does not guarantee success. To understand why experienced engineers choose professional turnkey partners—and why others struggle with repeated rework—it helps to look at where PCB assembly projects actually fail.

What Problems Does Quick Turn Turnkey PCB Assembly Solve for Engineers?

From an engineering perspective, most PCB assembly delays trace back to coordination failures, not fabrication speed.

Common pain points include:

-

Fragmented responsibility between PCB fab, component suppliers, and assembly houses

-

Last-minute BOM issues, including obsolete or mismatched parts

-

SMT yield problems caused by rushed placement or poor stencil design

-

Insufficient testing, resulting in non-functional prototypes

A proper quick turn turnkey PCB assembly service addresses these issues by consolidating ownership. One team is responsible for the entire outcome—not just moving files through a system.

This distinction matters most when schedules are tight and design margins are thin.

Why Low-Cost Turnkey PCB Assembly Platforms Create Hidden Risks

Many engineers have experimented with low-cost turnkey platforms. They look efficient on the surface: upload files, get a price, wait for delivery. For simple boards, this can work. For anything else, problems emerge quickly.

Typical platform limitations include:

-

No engineering-driven BOM validation

-

Silent component substitutions without lifecycle analysis

-

Minimal feedback on DFM/DFA issues

-

AOI-only inspection with no functional verification

These services are optimized for transaction speed, not engineering accountability. When something goes wrong, the burden shifts back to the customer—debugging failures that could have been prevented upstream.

Professional turnkey PCB assembly is intentionally different. It prioritizes risk reduction over lowest possible unit cost, which is why it appeals to industrial, medical, and professional electronics teams—not hobbyists or price-first buyers.

What Is a Turnkey PCB Assembly — and What It Is Not

At its core, turnkey PCB assembly means a single provider manages:

-

PCB fabrication

-

Component sourcing

-

SMT and through-hole assembly

-

Inspection and testing

What it is not:

-

A self-service ordering platform

-

A guarantee of the lowest price

-

A “hands-off” process with no engineering dialogue

True turnkey PCB assembly includes human oversight, engineering review, and change control. That’s what enables fast turnaround without sacrificing reliability.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

How Fast Turnkey PCB Assembly Service Actually Works

Understanding the process helps explain why some suppliers deliver consistent results—and others don’t.

PCB Fabrication and Stack-Up Control

Quick turn builds still require disciplined stack-up decisions. Impedance control, copper balance, and material selection all influence assembly yield and solder joint quality.

👉 Reference resource placeholder: IPC-2221 design guidelines

Component Sourcing and BOM Optimization

Component sourcing is often the highest-risk variable in fast builds.

A professional turnkey PCB assembly including component sourcing will:

-

Verify manufacturer part numbers

-

Check lifecycle and NRND status

-

Optimize alternates without breaking electrical intent

This is where BOM optimization directly affects schedule stability.

👉 Reference resource placeholder: Component lifecycle databases

SMT Placement Challenges in Quick Turn Builds

Speed amplifies SMT risks. Fine-pitch parts, BGAs, and QFNs demand precise paste deposition and placement accuracy.

Common challenges include:

-

Tombstoning on passives

-

Insufficient solder volume

-

Package warpage during reflow

Experienced assemblers adjust stencil thickness, aperture design, and reflow profiles—rather than relying on default settings.

Key SMT Placement Challenges in Quick Turn PCB Assembly—and How We Solve Them

Fast assembly does not excuse poor process control.

Key risk areas:

-

Stencil design tradeoffs between speed and yield

-

Component orientation errors in dense layouts

-

Thermal imbalance across the board

Solutions include:

-

Engineering-led stencil review

-

Pre-production placement verification

-

Process tuning based on board-specific constraints

These steps slow nothing down—but prevent rework that kills schedules.

Post-Soldering Risks That Delay Prototypes

AOI Inspection Limits in Low-Volume Builds

AOI inspection is powerful—but not sufficient on its own.

AOI struggles with:

-

Hidden solder joints (e.g., BGAs)

-

Marginal wetting defects

-

Electrical functionality

This is why AOI inspection must be paired with engineering judgment, not treated as a checkbox.

When Functional Testing Is Mandatory, Not Optional

Functional testing closes the loop between assembly and real-world performance.

Quick turn PCB assembly with testing reduces:

-

Debug cycles

-

Finger-pointing

-

Repeat builds

Even basic power-up or interface testing dramatically improves prototype confidence.

👉 Reference resource placeholder: Functional test methodologies

Turnkey PCB Assembly with SMT and DIP for Mixed-Technology Boards

Many industrial designs still combine SMT and through-hole components.

Challenges include:

-

Thermal stress during selective soldering

-

Manual solder consistency

-

Mechanical reliability

Turnkey PCB assembly with SMT and DIP requires planning—not improvisation—especially under time pressure.

Quick Turn PCB Assembly with Testing — When Speed Must Still Be Verified

Speed without validation creates false progress.

A risk-based testing strategy may include:

-

ICT for high-pin-count designs

-

Functional testing for system-level confidence

-

Targeted probing on critical nets

The goal is not exhaustive testing—but meaningful verification. For teams sourcing quick turn turnkey PCB assembly, evaluating a supplier goes beyond lead time and pricing. In practice, many experienced engineers apply the same logic used in a formal SMT factory audit—reviewing process control, inspection capability, documentation discipline, and change management before committing to production.

Turnkey PCB Assembly for Rapid Prototyping vs Low-Volume Production

Rapid prototyping emphasizes learning speed. Low-volume production emphasizes repeatability.

Mistakes happen when:

-

Prototypes are treated like mass production

-

Feedback loops are ignored

-

Engineering insights aren’t captured

A good turnkey PCB assembly for rapid prototyping accelerates iteration—not just delivery.

Why Industrial and Professional Electronics Require a Different PCB Assembly Service

Industrial electronics demand:

-

Traceability

-

Process documentation

-

Long-term reliability

These requirements are incompatible with platform-style assembly models. That’s why experienced teams choose PCB assembly services designed for industrial electronics, not consumer experimentation.

Choosing a Quick Turn PCB Assembly Manufacturer — What Engineers Should Evaluate

When evaluating a quick turn PCB assembly manufacturer, engineers should ask:

-

Who owns DFM/DFA decisions?

-

How are BOM changes handled?

-

What testing is standard—not optional?

-

How transparent is communication?

The answers reveal whether a supplier is a partner—or just an order processor.

Quick Turn PCB Assembly China Manufacturer — Engineering Control vs Platform Outsourcing

China remains a global manufacturing hub. The risk lies not in geography—but in process control.

A professional turnkey PCB assembly China manufacturer provides:

-

Engineering-managed sourcing

-

Quality system enforcement

-

Clear communication channels

Platform outsourcing removes these safeguards.

FAQs

1. How fast can I get boards from a quick turn turnkey PCB assembly service?

With a professional quick turn turnkey PCB assembly, engineers can typically receive assembled prototypes in 3–7 working days, depending on BOM readiness and testing requirements. Speed depends less on assembly labor and more on component sourcing, DFM/DFA review, and SMT process control. Services that offer fast quotes but lack engineering oversight often lose time later through rework or delays.

2. How much should a quick turn turnkey PCB assembly really cost?

The cost of quick turn PCB assembly with components reflects more than labor. Pricing includes component availability, BOM optimization, SMT/DIP complexity, inspection, and testing. Extremely low prices usually mean limited sourcing control, minimal testing, and higher functional risk. For industrial or professional electronics, the true cost metric is first-pass success, not the lowest invoice.

3. What determines the lifespan and reliability of an assembled PCB?

PCB lifespan depends heavily on assembly quality, not just design. Factors such as solder joint integrity, thermal profiling, material selection, and post-solder inspection all affect long-term reliability. A turnkey PCB assembly service for industrial electronics improves lifespan by combining controlled SMT processes, AOI inspection, and functional testing—especially critical for low-volume and quick-turn builds.

4. Is quick turn turnkey PCB assembly suitable for low-volume production?

Yes. Low volume turnkey PCB assembly is ideal when designs are stable but volumes don’t justify mass production tooling. The key advantage is engineering-managed consistency—the same sourcing, SMT setup, and testing logic used in prototypes can be maintained across small production runs, reducing variation and avoiding the risks common in platform-based assembly services.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary

Quick turn turnkey PCB assembly is not about being the cheapest option—it’s about reducing risk while moving fast. Engineers who prioritize process control, testing, and accountability get prototypes that work, timelines that hold, and fewer surprises downstream.

Ready to move faster—with fewer risks?

If your project requires real PCB assembly expertise, engineering communication, and controlled execution, a professional turnkey approach is the shortest path from design to working hardware.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!