Quick Leads-PCBA

Choosing wrong costs more than money

Choosing the wrong HDI PCB manufacturer in China can cost you time, money, and even your reputation with customers. From unclear capabilities to missed deadlines and poor signal performance — I’ve seen too many engineers and procurement leads stuck with reworks. Let me share five critical lessons that can help you avoid costly mistakes and find a reliable partner — especially when you’re after no-MOQ flexibility and fast delivery.

When choosing a reliable HDI PCB manufacturer in China, check for true no-MOQ policies, fast-turnaround capabilities, advanced stack-up options, quality certifications, and real-time engineering support. Avoid vague quotes, outdated processes, and communication delays. A good supplier will offer HDI PCB fabrication with fast delivery and no minimum order — while still meeting OEM standards.

Let’s break this down.

1. How to Choose a Reliable HDI PCB Manufacturer in China?

If you’ve ever searched HDI PCB manufacturer China, you’ve probably noticed every factory claims “high quality,” “low cost,” and “fast turnaround.” But behind those claims, here’s what really separates a professional from a production risk:

-

Certifications matter: ISO9001, UL, RoHS — these aren’t just logos. They prove the factory follows global standards.

-

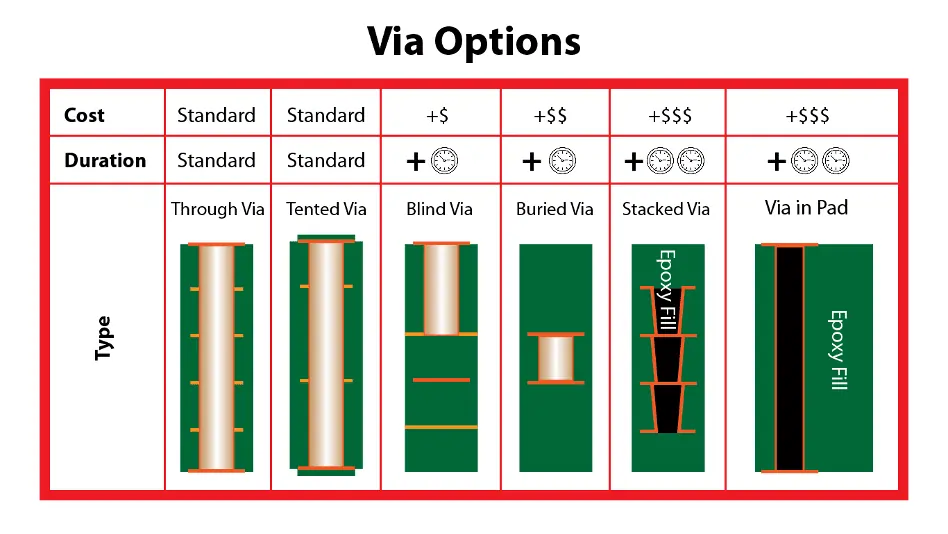

Stack-up experience: Can they handle 6–10 layers with blind/buried vias? Do they help optimize your impedance setup?

-

No MOQ ≠ Fast: Some promise small batches… but delay them to prioritize bulk orders.

Here’s a quick breakdown:

📊 Traditional Factory vs. Verified HDI PCB Supplier

| Feature | Basic Factory in China | Verified HDI Supplier (like us) |

|---|---|---|

| Certifications | Often missing | ISO9001, UL, RoHS, IPC-compliant |

| Engineering Support | Minimal | Real-time DFM & design review |

| Delivery Transparency | Delayed updates | Online tracking & daily reports |

| MOQ Policy | Vague or hidden | Truly no MOQ, written in contract |

| Stack-up Capabilities | Limited (≤4 layers) | Up to 10-layer HDI, impedance tuned |

🟢 Tip: Ask for their Gerber review report before placing your order. If they can’t provide clear feedback on impedance, via-in-pad, or copper balancing, move on.

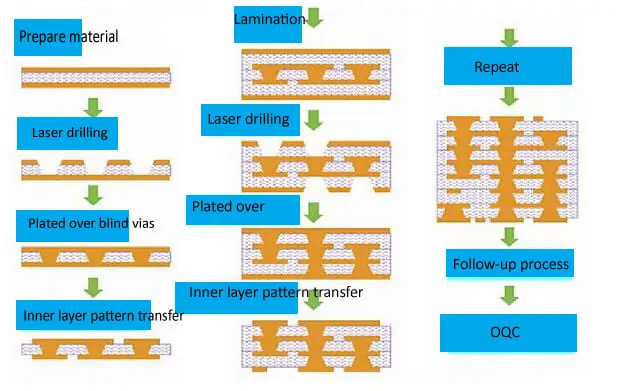

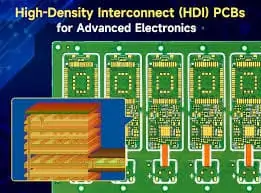

2. What Are the Technical Challenges in HDI PCB Manufacturing?

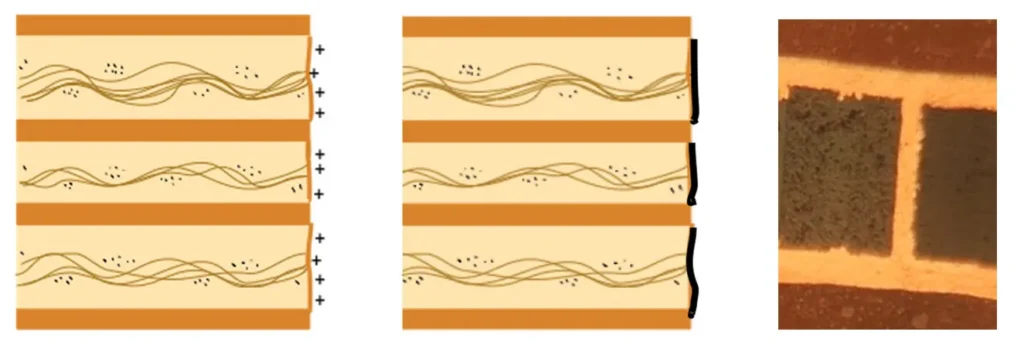

HDI PCB (High-Density Interconnect) design is no joke. You’re dealing with microvias, ultra-thin layers, controlled impedance, and tight tolerances. If your supplier is just a volume-run producer, they’ll likely cut corners.

Here’s what can (and often does) go wrong:

-

Microvia failure — caused by poor laser drilling or uneven plating

-

Delamination between layers — from inadequate lamination pressure or materials

-

Signal degradation — from bad stack-up or trace geometry

But the right partner solves this with:

-

Sequential lamination for 8+ layer PCBs

-

Controlled impedance verification

-

100% AOI + X-ray for inner layers

📊 Common HDI Manufacturing Issues & Fixes

| Problem | Root Cause | Our Solution |

|---|---|---|

| Microvia Failure | Poor drilling process | Laser-controlled via drilling |

| Layer Misalignment | Bad lamination alignment | 6-step sequential lamination |

| Signal Integrity Loss | Weak stack-up configuration | Impedance simulation + review |

| Pad Lifting on Reflow | Low Tg base materials | Tg 180+ and RoHS-compliant boards |

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

3. Why Is “No MOQ” Misleading Without Fast Delivery?

A lot of suppliers shout “NO MOQ” — but when you place an order for 2 or 3 boards, they delay it. Why? Because their lines prioritize bulk runs. Small batch customers go to the back of the line.

We’ve had multiple clients switch to us because they were stuck for 10+ days waiting on just 5 boards.

Here’s what a real no-MOQ + fast delivery system should look like:

-

Parallel SMT lines for prototypes

-

Priority slotting for low-volume orders

-

Courier-level logistics tracking (yes, we even share DHL pickup scans)

📦 A Real Case:

A startup needed two 6-layer impedance-controlled boards for a pitch demo. Their previous supplier said “2-3 days” but took 8. We delivered in 48 hours with stack-up verification screenshots.

4. What Defines the Best Chinese HDI PCB Suppliers for OEM Projects?

When you’re scaling up or serving enterprise clients, you can’t afford surprises. Here’s what top OEM buyers look for in a best Chinese HDI PCB supplier:

-

Repeatable processes: Same output every time, down to trace width

-

Component traceability: From solder paste lot to final assembly

-

Advanced QA: In-line AOI, X-ray, flying probe + functional test

We built our OEM-focused services to meet exactly those needs:

📊 OEM-Grade Supplier Checklist

| Requirement | Why It Matters | Do We Provide It? |

|---|---|---|

| Batch-level traceability | Crucial for product recalls | ✅ Yes |

| RoHS-compliant process | Needed for EU/US exports | ✅ Yes |

| NDA + Data Protection | IP security is key | ✅ Yes |

| Repeatability QC Logs | Ensures consistent batches | ✅ Yes |

| Component Sourcing | Avoid fakes + EOL parts | ✅ Yes (Authorized channels only) |

5. What Questions Should You Ask Before Committing to a Manufacturer?

Most mistakes happen because people didn’t ask the right questions upfront. Whether you’re a seasoned engineer or new to China sourcing, here’s a checklist to help you evaluate:

📋 Must-Ask Questions

-

Can I see your HDI line photos (not stock images)?

-

What’s your fastest lead time for a 6-layer HDI prototype?

-

Do you provide a full DFM review before I place payment?

-

How do you handle impedance verification?

-

What stack-up materials do you use — can I request Tg180?

These are the exact questions our clients asked before switching to us.

FAQs

1. How do I choose a reliable HDI PCB manufacturer in China?

To choose a reliable HDI PCB manufacturer in China, look beyond low prices. Check for ISO and RoHS certifications, real factory photos, transparent “no MOQ” policies, and a fast delivery record. A trustworthy partner will provide full DFM feedback and support for HDI PCB manufacturing without MOQ. Don't forget to ask about blind and buried via experience — that's critical for complex high density interconnect PCB work.

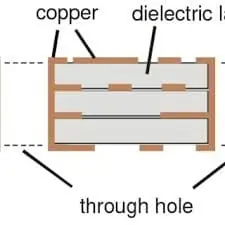

2. What’s the difference between HDI PCB and regular PCB boards?

A standard PCB uses simple through-hole vias and fewer layers, while an HDI PCB packs more power into a smaller space using microvias, laser drilling, and tight impedance control. HDI boards are ideal for smartphones, wearables, and compact electronics. If you're sourcing from a reliable HDI PCB manufacturer in China, make sure they support advanced PCB stack-up for HDI and impedance simulation.

3. What are the advantages of using HDI PCBs for OEM applications?

HDI PCBs allow more components in less space, better signal integrity, and higher performance — ideal for OEMs needing speed and efficiency. They're also more durable in harsh environments. The best Chinese HDI PCB suppliers for OEM will offer controlled impedance, traceability, and turnkey assembly. For small runs, look for low volume HDI PCB assembly China with guaranteed delivery timeframes.

4. What are the golden rules for HDI PCB design success?

Start with a clear stack-up strategy, follow tight via-in-pad guidelines, and always verify impedance. Use PCB design for manufacturing (DFM) early to avoid errors. One rule of thumb: “Design once, prototype smart.” Choose partners offering PCB prototyping China with real-time DRC (design rule check) and feedback. Bonus tip: the right electronics manufacturing services partner will flag mistakes before production starts.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🔚 Summary

Getting HDI PCB manufacturing right — especially in China — isn’t about finding the cheapest quote. It’s about partnering with someone who gets the technical details, communicates clearly, and delivers consistently. That’s what separates an order from a supply chain success story.

Have files ready or just exploring? Let’s talk.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!