Quick Leads-PCBA

Choosing the wrong solder can ruin your PCB reliability, spike returns, or worse—lock you out of global markets. For electronics manufacturers and sourcing leads, RoHS compliance isn’t just about passing regulations—it’s about scaling smarter and staying competitive.

RoHS-compliant solder improves PCB reliability by eliminating hazardous substances like lead, aligning with EU electronics compliance standards. Using lead-free alloys such as SAC305 ensures safer, more durable assemblies while enabling access to global markets. RoHS soldering also prevents issues like tin whiskers, supports eco-friendly production, and meets international regulations including REACH and IPC-A-610.

Let’s break down why your solder choices directly influence compliance, performance, and your ability to sell worldwide—especially if you’re sourcing from China or scaling up EMS production.

Why is RoHS Important in PCB Design?

RoHS (Restriction of Hazardous Substances) isn’t just a European law anymore. It’s the baseline for global electronics compliance. If your PCBs contain lead, cadmium, mercury, or four other banned substances—you’re not getting into the EU or China legally.

But compliance impacts more than the Bill of Materials. It touches every design decision:

-

What solder alloy do we use?

-

Can our laminate handle lead-free reflow temps?

-

Will the components’ finish survive RoHS-compatible assembly?

We’ve seen clients redesign entire assemblies to stay within compliance and still hit their performance targets. If you’re working on medical, automotive, or industrial boards—RoHS isn’t optional.

What is RoHS-Compliant Solder, and Why Does It Matter?

At its core, RoHS-compliant solder means no lead. The industry standard replacement? SAC305 — a tin-silver-copper alloy that meets both REACH and RoHS standards and performs reliably under reflow stress.

Let’s compare it:

| Feature | RoHS-Compliant (SAC305) | Traditional Leaded (SnPb) |

|---|---|---|

| Melting Point | 217–221°C | ~183°C |

| Health Impact | Non-toxic | Toxic (Lead) |

| Global Market Eligibility | ✅ Full access | ❌ Restricted |

| Cost | ~15–30% higher | Lower |

| Long-Term Reliability | Stronger joints, better fatigue resistance | Good but outdated |

Yes, it’s hotter and costlier—but worth every cent for a cleaner assembly and open access to markets like the EU, Japan, and even China, where China EMS RoHS compliance is now expected.

Are PCBs RoHS Compliant by Default?

Not necessarily. A common misconception is that a “green” PCB means it’s compliant. But true RoHS compliance includes:

Lead-free solder

RoHS-grade laminates and masks

Component sourcing with certified finishes

Full documentation (CE + RoHS test reports)

We often hear from clients trying to source RoHS compliant PCB assembly in China, only to discover their supplier uses outdated solder paste or uncertified components. That’s where things get risky—not only for product function but also for legal import clearance.

What Are the Benefits of RoHS Compliance?

Let’s keep it real. The benefits go way beyond passing customs:

Wider Market Access

Selling in the EU, UK, and Asia? You’ll need proof of RoHS and possibly REACH compatibility.Sustainability Branding

More consumers (and B2B buyers) want green tech. RoHS proves your supply chain walks the talk.Worker Safety

Less exposure to toxic fumes during reflow and hand soldering.Cleaner End-of-Life Recycling

RoHS-aligned products break down easier and pose less risk in landfills.

These aren’t just checkboxes. They’re signals of a brand that thinks long-term.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Common Industry Pain Points with Lead-Free PCB Assembly

Here’s where RoHS starts getting technical. Going lead-free isn’t plug-and-play. You’re going to face challenges like:

-

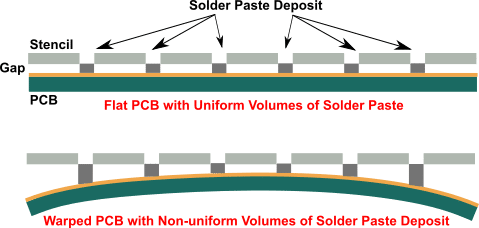

Higher reflow temps = warping risks

-

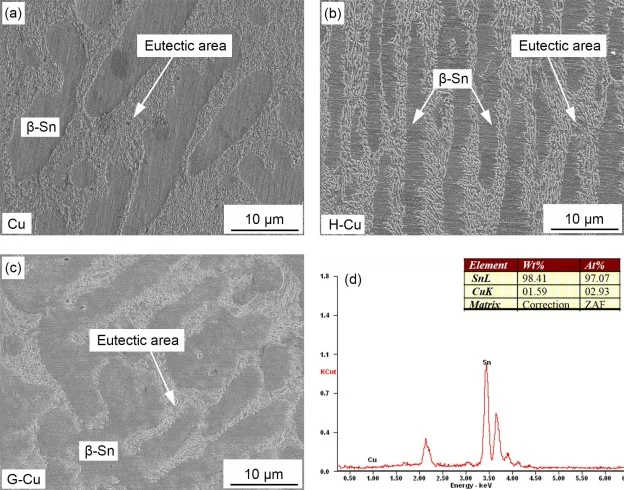

Tin whiskers growing in dense BGAs or fine-pitch ICs

-

Component cracking due to mismatched CTEs

-

Void formations in solder joints

-

Longer wetting time, requiring tighter reflow profiling

Let’s map that out:

| Pain Point | Why It Happens | Our Technical Solution |

|---|---|---|

| PCB Warpage | Higher reflow temps | Pre-bake protocol & low-CTE laminates |

| Tin Whiskers | Sn-only alloys | Use SAC305 & protective conformal coating |

| Higher Solder Cost | Precious metals | Bulk sourcing + automated paste management |

| Delay in Certifications | EMS lacks RoHS expertise | Internal RoHS lab testing & IPC-A-610 verification |

SMT Process Adjustments for RoHS

If your supplier isn’t optimizing their SMT line for RoHS, your product will suffer. Here’s what RoHS-compliant SMT looks like:

-

Reflow profile tailored to SAC305

-

Nitrogen atmosphere where needed to reduce oxidation

-

RoHS-compatible stencils and pastes

-

X-ray inspection for void detection in QFNs and BGAs

-

Conformal coating to reduce tin whisker risks

We follow IPC-A-610 standards closely and offer solder joint inspection photos as part of our RoHS compliant soldering service. Transparency builds trust, and you deserve to see what goes on your board.

IPC guidance shows that lead-free soldering requires narrower process windows and tighter reflow control in RoHS 6 environments.

Real Compliance = Real Market Access

If you’re exporting or selling to big-box retailers, they want documentation—now more than ever.

-

EU customs need RoHS and CE proof.

-

China RoHS 2.0 checks your full BOM and process.

-

Walmart/Best Buy may demand environmental proof on file.

If you’re buying from a low MOQ RoHS PCB manufacturer, make sure they’re not cutting corners. We’ve had clients burned by “green” PCBs that failed testing in Europe. Some exceptions exist for high-lead solders in very specific applications, but the manufacturer must still self-declare RoHS conformity.

What you want is a partner that offers:

-

Certified lead-free materials

-

On-demand documentation

-

BOM traceability from solder to silkscreen

We do all that—because your rep and revenue depend on it.

What Makes Our Services Different?

Let’s talk about what we do differently for clients who want real, reliable RoHS solutions:

-

✅ In-house RoHS lab: Every board gets checked for banned substances.

-

✅ Dedicated compliance officer: Helps prepare docs for customs/imports.

-

✅ RoHS solder traceability: You’ll always know which paste we used.

-

✅ Low-volume to mass production: Whether it’s 10 boards or 10,000, we can help.

-

✅ Fast turnaround lead-free PCB assembly with precise reflow profiling.

-

✅ Fully documented RoHS compliant soldering service—ready for audits or CE.

Looking for a low MOQ RoHS PCB manufacturer in China? We offer 5-day turnaround on <50pcs runs, with full RoHS traceability—even at prototype stage.

That’s why we invite clients to audit our SMT lines and documentation processes directly—or follow this step-by-step factory audit guide to evaluate any EMS partner’s RoHS compliance readiness.

FAQs

1. Is RoHS compliance mandatory in the USA?

While RoHS isn't federally mandated in the U.S., many states (like California) have their own environmental electronics regulations. Plus, if you're exporting or supplying major retailers, RoHS compliance becomes essential. Working with a RoHS compliant soldering service ensures your products are ready for both domestic and international markets—even when compliance isn't legally required yet.

2. What happens if my product isn't RoHS compliant during customs checks?

If your PCB assembly isn't RoHS compliant, your shipment could be rejected, delayed, or fined—especially at EU or China ports. Even minor noncompliance like using outdated solder paste can cause issues. Partnering with a China EMS RoHS compliance expert helps avoid costly mistakes and ensures all documentation and materials meet global import standards.

3. Can I get RoHS-compliant PCB prototyping with low volume orders?

Absolutely. We specialize in low MOQ RoHS PCB manufacturing, meaning you can prototype lead-free assemblies without minimum quantity stress. Whether you need 5 or 50 boards, our fast-turn services use lead-free PCB assembly processes and RoHS-certified materials—perfect for startups or design validation runs.

4. How does RoHS compliance affect PCB solder joint reliability?

Lead-free alloys like SAC305 behave differently than traditional SnPb. Without the right thermal profile and inspection, joints may suffer from cracks or voids. That’s why our PCB soldering with RoHS lead-free materials includes optimized SMT profiles and X-ray inspection—ensuring solder joint reliability even under mechanical or thermal stress.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary & Final Thoughts

RoHS isn’t a check-the-box item—it’s a design-to-delivery strategy. When you pick the right solder and partner, you unlock better boards, fewer risks, and wider market access. Got a project? Let’s talk.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!