Quick Leads

SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

Updated for 2026: This guide has been reviewed and updated to reflect the latest SMD size codes and trends in PCB design for 2026.

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

What is SMD Size Code and Why is it Important?

SMD (Surface-Mounted Device) size codes represent the surface mount dimensions of electronic components—such as resistors and capacitors—used in PCB (Printed Circuit Board) assemblies. These standardized codes are essential for ensuring proper component placement, accurate power ratings, and overall manufacturing efficiency.

Engineers often refer to SMD size code charts when selecting components, especially for common package types like 0603 or 0805. However, newcomers may find these codes confusing due to different naming systems used globally for SMD resistor sizes and capacitor codes.

Learn more about PCB design basics and how component selection impacts your projects.

Common SMD Sizes

SMD components come in a variety of standardized package sizes, and each SMD size code corresponds to specific surface mount dimensions in either imperial or metric units. These codes help engineers select the appropriate components based on space constraints, electrical requirements, and automated assembly compatibility.

Here are the most common SMD resistor and capacitor sizes:

0201: The smallest standard SMD resistor size, often used in ultra-compact consumer electronics.

0402: Popular in mobile devices where space efficiency is critical.

0603: A balanced size for both consumer and industrial use, offering easier handling and solid electrical performance.

0805: Larger footprint than 0603, ideal for higher current or voltage—frequently compared as 0603 vs 0805 when designing for power vs space.

1206: Common in SMD capacitor codes and power components, used in industrial and high-power applications.

✅ Want to ensure your supplier’s SMT line meets international standards?

Check this [factory audit checklist for SMT manufacturers in China]

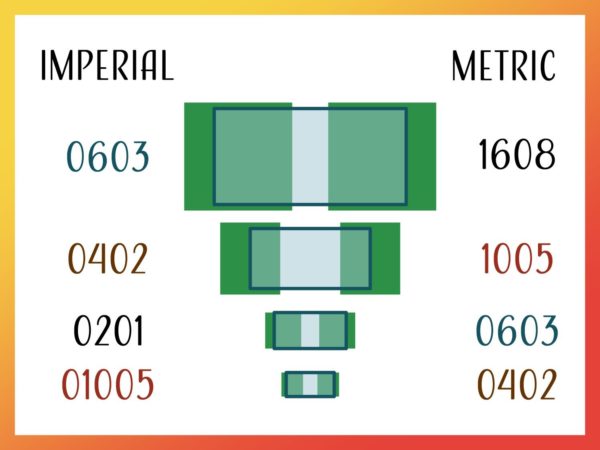

🔹 Differences Between Imperial and Metric SMD Size Codes

In global electronics manufacturing, SMD size codes are represented in either imperial units (inches) or metric units (millimeters). While the physical components are identical, the way their surface mount dimensions are labeled can vary depending on the region.

Here are two commonly used equivalents:

-

0603 (imperial) = 1608 (metric)

-

0805 (imperial) = 2012 (metric)

This often leads to confusion when comparing packages like 0603 vs 0805 or sourcing components internationally. Understanding these unit systems ensures that the parts you order match your PCB layout and assembly requirements, avoiding costly mistakes in high-density designs.

🔹 How SMD Size Affects Component Layout on the PCB

The size of an SMD component directly affects how densely components can be arranged on a PCB. Smaller packages like 0201 or 0402 enable compact layouts but require high-precision placement equipment and tighter process control. On the other hand, larger packages like 0805 or 1206 allow for easier handling and more forgiving tolerances during assembly.

Choosing between sizes such as 0603 vs 0805 often comes down to a trade-off between space savings and manufacturing reliability. These choices impact your overall surface mount layout and can affect everything from solder joint quality to inspection and testing.

👉 If you’re unsure which SMD resistor size or package fits your design, explore our SMT Assembly Services to get expert guidance with no MOQ.

🔹 Common SMD Package Types and Sizes

SMD components come in various package types, each defined by its unique size code that corresponds to specific physical dimensions and electrical properties.

Resistors: Most common SMD resistor sizes include 0603, 0805, and 1206, depending on power handling and board space.

Capacitors: Similar in packaging to resistors, but often listed under separate SMD capacitor codes, with smaller packages like 0402 used in high-density designs.

Transistors: Typically found in slightly larger packages such as SOT-23, or surface-mount equivalents of 0603/0805, especially in analog and switching circuits.

Each component’s size selection impacts not just placement but also thermal behavior, current handling, and yield rate during assembly. For a complete overview of package options, check our PCB parts code guide for decoding markings.

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

🔹 How to Choose the Right SMD Size

Choosing the correct SMD size is crucial for balancing performance, manufacturability, and cost. Several factors influence the decision:

Application Type: Smaller packages like 0402 or 0201 are ideal for compact devices such as smartphones or wearables. In contrast, larger packages like 0603, 0805, or 1206 are preferred in power supply, industrial control, or high-current applications.

Power Handling: Generally, the SMD resistor size increases with power rating. For instance, 0805 resistors can typically handle more power than 0402, which is essential for thermal stability.

Manufacturing Process: While smaller sizes allow for dense layouts, they also require more precise equipment and are harder to inspect or rework. This adds complexity and cost during production.

Selecting between packages like 0603 vs 0805 depends on your priorities—whether it’s saving space, increasing reliability, or improving yield rate. These trade-offs directly impact your surface mount layout and long-term performance.

👉 For a smooth production process, explore our SMT Assembly Services designed to handle high-precision SMD components with no MOQ and fast delivery.

🔹 SMD Size Chart: Power Handling and Applications

As a general rule, power handling increases with package size. Larger components have wider pads and more copper contact area, enabling better heat dissipation.

Here’s a simplified comparison:

| SMD Size | Typical Power Rating | Recommended Use |

|---|---|---|

| 0402 | 0.063W | Mobile devices, signal lines |

| 0603 | 0.10W | Consumer electronics, sensors |

| 0805 | 0.125–0.25W | Power circuits, motor drivers |

| 1206 | 0.25–0.50W | Industrial, automotive systems |

🧠 Proper size selection prevents overheating, improves solder joint quality, and reduces long-term failure rates.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliver🔹 Conclusion

Understanding SMD size codes is essential for selecting the right resistors, capacitors, and other surface-mount components for your project. By learning how these codes relate to surface mount dimensions, you can ensure proper fit, optimize your PCB layout, and meet power or performance requirements effectively.

Whether you’re choosing between 0603 vs 0805 or specifying SMD resistor sizes for your board, making the right decision at this stage will streamline your manufacturing process and reduce the risk of costly errors.

🔧 Need help selecting components?

Our engineering team specializes in component sourcing, BOM verification, and SMT assembly — all with no MOQ and rapid turnaround.👉 Contact us now to ensure your next PCB project starts with the right components and finishes with reliable results.

✅ Want to ensure your supplier’s SMT line meets international standards?

Check this [factory audit checklist for SMT manufacturers in China]

Additional Resources:

- Top 10 PCB Assembly Manufacturers in Europe: A Comprehensive Guide

- SMT Factory Audit Checklist (2025): 20 Must-Ask Questions Before You Order from China

- Top 15 EMS Companies Supporting UK & European Electronics Brands [2025 Ranking]

- How to Audit an SMT Assembly Factory: A Step-by-Step Guide

- 2025 Global Ranking: Top 10 Quick-Turn PCB Assembly Companies for Rapid Prototyping (With Instant Quote)

Need help sourcing these components or assembling your PCB? Get a Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCB Assembly

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!