Quick Leads-PCBA

Introduction: The Real Challenges of SMT PCB Assembly

In today’s world, electronics are getting smaller, faster, and more complex. Whether it’s for automotive, medical devices, aerospace, or consumer electronics, the demand for high-density, high-performance circuit boards is at an all-time high. But let’s be real—getting SMT PCB assembly done right isn’t easy.

- Component shortages delay production.

- Defects like solder bridging and tombstoning cause failures.

- Long lead times slow down product launches.

- Finding a reliable assembly partner feels like a gamble.

That’s where our turnkey SMT PCB assembly services come in. We take care of fabrication, component sourcing, and assembly—so you don’t have to. And whether you need prototypes, small batches, or full-scale production, we deliver high-quality, fast-turnaround solutions with no MOQ requirements.

Let’s break it down. 👇

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

What is Surface Mount Technology (SMT) in PCB Assembly?

Before we dive into solutions, let’s cover the basics.

Surface Mount Technology (SMT) is the method of mounting electronic components directly onto the surface of a PCB (Printed Circuit Board), instead of inserting them into drilled holes (Through-Hole Technology, THT).

Why SMT? The Big Advantages

✅ Smaller, denser PCBs – Ideal for compact electronics.

✅ Automated & efficient – Faster, more cost-effective assembly.

✅ Better electrical performance – Lower resistance and inductance.

✅ More design flexibility – Enables multi-layer, high-density boards.

The bottom line? SMT is the go-to choice for modern electronics.

The Biggest Pain Points in SMT PCB Assembly

Despite its advantages, SMT PCB assembly has its fair share of challenges. If you’ve dealt with failed PCBs, supply chain delays, or inconsistent quality, you’re not alone. Here are the top issues we see in the industry—and how we solve them.

1️⃣ Component Shortages & Sourcing Nightmares

👉 The problem: Finding the right components at the right price is tough—especially with global shortages.

🔹 Our solution: We offer turnkey SMT PCB assembly with component sourcing included. Our strong supplier network ensures access to high-quality, in-stock components, reducing lead times and avoiding counterfeits.

2️⃣ Quality & Reliability Issues

👉 The problem: Poor solder joints, misaligned components, and thermal stress cause PCB failures.

🔹 Our solution:

✔️ IPC Certified SMT PCB Assembly – We follow strict industry standards.

✔️ Automated Optical Inspection (AOI) & X-ray Inspection – Catch defects before they become failures.

✔️ Reflow soldering with precise temperature control – Ensures perfect joints, even for BGA and QFN components.

3️⃣ Long Lead Times & High Costs

👉 The problem: Slow turnaround times delay projects, and setup costs make low-volume runs expensive.

🔹 Our solution:

✔️ Quick-Turn SMT PCB Assembly – We offer express PCB assembly for tight deadlines.

✔️ Low-Volume Surface Mount PCB Assembly – Ideal for prototyping & small batch production.

✔️ No MOQ PCB Assembly SMT – Order only what you need—no unnecessary costs.

Even with advanced SMT PCB assembly processes, common issues like solder bridging, tombstoning, and misaligned components can occur. These defects lead to failed PCBs, production delays, and increased costs. That’s why we implement Automated Optical Inspection (AOI) and X-ray inspection to catch problems early. For a deeper look at the most frequent PCB assembly issues and how to prevent them, check out this guide: here.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

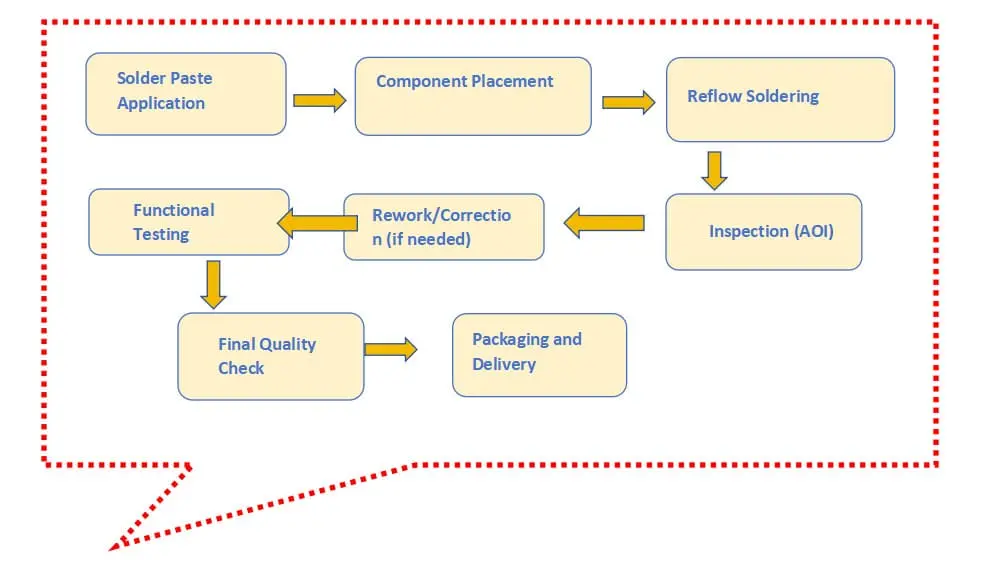

Our SMT PCB Assembly Process – How It Works

We don’t just assemble PCBs—we optimize the entire process to ensure speed, quality, and cost-effectiveness.

Step 1: DFM (Design for Manufacturability) Check

Before production starts, we review your design to catch any issues that could cause defects or delays.

Common issues we fix:

✔️ Pad size mismatches

✔️ Insufficient solder mask clearance

✔️ Thermal imbalance problems

✔️ Incorrect component footprints

Before production begins, a DFM (Design for Manufacturability) review is essential to identify potential issues such as pad misalignment, insufficient solder mask clearance, or thermal imbalance. Optimizing PCB design for SMT assembly ensures a smooth manufacturing process and reduces costly rework. Siemens provides a valuable resource on best practices for designing PCBs optimized for SMT assembly, which you can read here.

Step 2: Stencil Printing & Solder Paste Application

We apply high-precision solder paste using laser-cut stainless steel stencils, ensuring consistent paste deposition.

Why this matters: A bad stencil = bad solder joints = failed PCB.

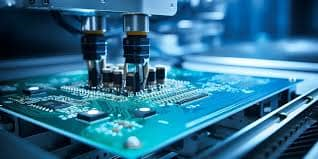

Step 3: Pick-and-Place Assembly

Using high-speed robotic machines, we place components with micrometer-level accuracy. Even tiny 01005 components? No problem.

Step 4: Reflow Soldering

The assembled PCB goes through a controlled heating process, where the solder paste melts and solidifies, forming strong, reliable solder joints.

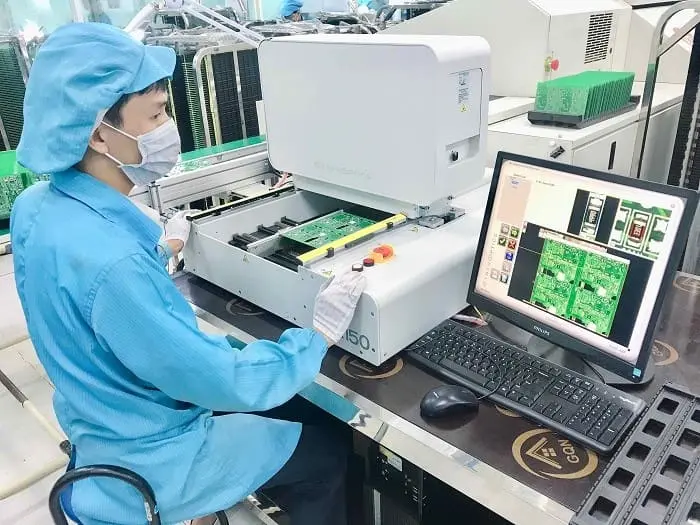

Step 5: Quality Control & Testing

We use:

✔️ AOI (Automated Optical Inspection) to detect misalignments or missing components.

✔️ X-ray Inspection for BGA and fine-pitch components.

✔️ Functional Testing (if required) to verify real-world performance.

Surface Mount Technology (SMT) involves multiple stages, including solder paste application, pick-and-place, reflow soldering, and automated inspection. Each step must be executed with precision to ensure a high-quality PCB assembly. For a detailed breakdown of the entire SMT assembly process, you can refer to this comprehensive guide on PCB assembly process from Sierra Circuits here.

How Much Does SMT PCB Assembly Cost?

One of the top questions we get: How much does PCB assembly cost?

It depends on:

- PCB size & complexity

- Number of layers (2-layer, 4-layer, etc.)

- Component sourcing (who supplies the parts?)

- Production volume (prototype, small batch, high-volume)

Industry Pricing Benchmarks

💰 Basic SMT assembly: $0.02 – $0.05 per square inch

💰 Complex boards (BGA, QFN, fine-pitch components): Higher costs

💰 Complete SMT line cost: From $100K to $8M, depending on equipment capacity

🔹 Our pricing advantage? We offer cost-effective, flexible options—from low-volume prototype runs to full production.

The cost of SMT PCB assembly depends on multiple factors—board complexity, material selection, assembly techniques, and component sourcing. Optimizing DFM (Design for Manufacturability) and choosing cost-effective assembly processes can significantly reduce expenses. If you’re looking to keep PCB assembly costs under control, this guide covers 10 key factors for affordable production: here.

Industries We Serve

We provide reliable SMT PCB assembly for industries where failure is NOT an option:

🚗 Automotive – ADAS, infotainment, power electronics

🏥 Medical – Wearable devices, diagnostic equipment

🛰️ Aerospace & Defense – Avionics, radar systems

📡 Telecom & IoT – 5G, smart devices, industrial sensors

🎮 Consumer Electronics – Smart gadgets, gaming peripherals

Each industry has unique challenges, and we tailor our manufacturing & testing to meet those demands.

Why Choose Our SMT PCB Assembly Services?

We’re not just another PCB assembler. Here’s what sets us apart:

✅ Turnkey SMT PCB Assembly – Fabrication + component sourcing + assembly in one place.

✅ No MOQ, Small Batch SMT PCB Assembly – Order exactly what you need.

✅ Fast SMT PCB Assembly Services – Express options available.

✅ Full-Service SMT PCB Manufacturing – From prototypes to high-volume production.

✅ High-Quality, IPC Certified SMT PCB Assembly – Built to industry standards.

✅ Advanced Testing & Quality Control – AOI, X-ray, functional testing.

Choosing the right SMT PCB assembly service goes beyond cost—it’s about quality, consistency, and reliability. A well-audited factory ensures strict quality control, proper equipment maintenance, and skilled technicians. If you’re sourcing a manufacturing partner, it’s crucial to audit their SMT assembly process to avoid hidden risks. Check out this step-by-step guide on auditing an SMT assembly factory to make an informed decision: here.

FAQs

1.How much does it cost to get a PCB assembled?

The cost of SMT PCB assembly depends on factors like board size, complexity, component sourcing, and order volume. On average, PCB assembly costs range from $0.02 to $0.05 per square inch, but prices increase for BGA, QFN, or fine-pitch components. Our Turnkey SMT PCB Assembly service helps optimize costs by handling fabrication, component sourcing, and assembly in one place. Whether you need Prototype SMT PCB Assembly or Low-Volume SMT PCB Assembly, we offer cost-effective, high-quality solutions with no MOQ.

2.Why is PCB assembly so expensive?

PCB assembly costs can be high due to advanced equipment, skilled labor, and strict quality control. Factors like component shortages, fine-pitch components, and multi-layer PCBs add complexity and cost. Our Reliable SMT PCB Manufacturing Services help reduce expenses by offering Quick-Turn SMT PCB Assembly and Express PCB Assembly SMT, ensuring fast turnaround without compromising quality. Plus, with our Full-Service SMT PCB Manufacturing, we streamline the entire process—from component sourcing to final assembly—to keep costs competitive.

3.How much does an SMT line cost?

Setting up an SMT PCB Assembly line is a major investment. A basic SMT production line costs $100,000 to $200,000, while high-speed, high-capacity SMT lines can exceed $8 million. Instead of handling equipment costs, maintenance, and labor, many companies choose Turnkey Surface Mount PCB Assembly services. Our High-Quality SMT PCB Assembly eliminates the need for in-house manufacturing, delivering cost-efficient, reliable SMT PCB solutions for prototyping, small batch, and large-scale production.

4.How long does a PCB service line last?

A well-manufactured PCB service line can last 10-20 years, depending on materials, soldering quality, and environmental conditions. Factors like poor-quality components, excessive heat, and high humidity can shorten lifespan. That’s why our IPC Certified SMT PCB Assembly ensures durability with AOI, X-ray inspection, and precision reflow soldering. Whether you need Low-Volume Surface Mount PCB Assembly or Full-Service SMT PCB Manufacturing, we guarantee high-reliability, long-lasting PCB assemblies built to withstand demanding applications.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Get Started with Reliable SMT PCB Manufacturing Today

You need high-quality, fast-turnaround SMT PCB assembly—without the hassle. We deliver cost-effective, precision-manufactured PCBs that meet the demands of modern electronics.

📩 Get a quote today and let’s build something great together. 🚀

🔧 Want to avoid these manufacturing issues with a trusted partner?

👉 See how our Turnkey PCB Assembly can help »

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!