Quick Leads

SMT vs. SMD: Key Differences in Electronics Manufacturing Explained

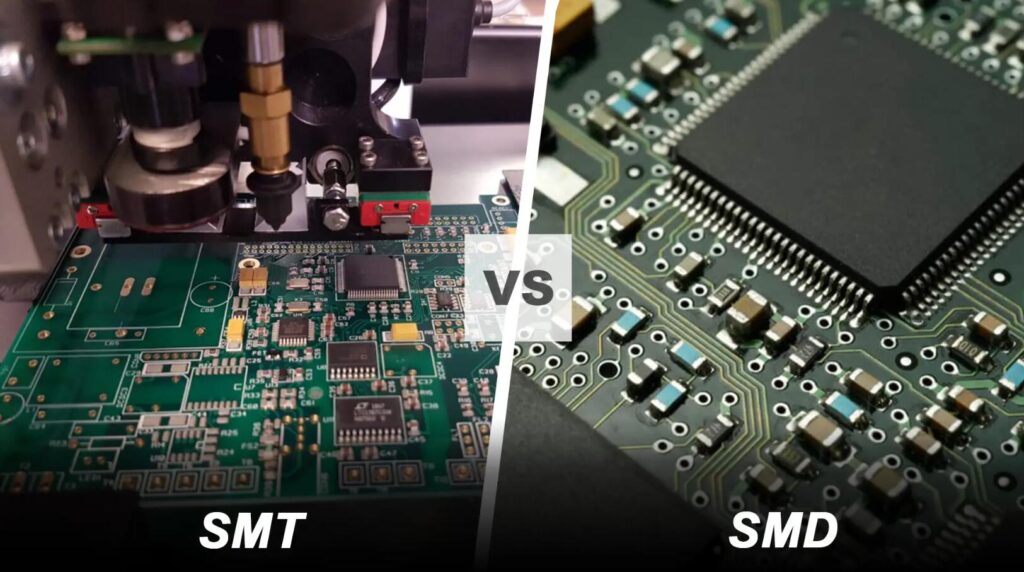

Learn the differences between Surface-Mount Technology (SMT) and Surface-Mount Devices (SMD) in electronics manufacturing.

Find out how each affects PCB assembly, product design, and production efficiency. In electronics manufacturing, it’s important to know the difference between Surface-Mount Technology (SMT) and Surface-Mount Devices (SMD).

These terms are often used interchangeably, but they represent different things in the PCB assembly process. In this article, we’ll explore the differences between SMT and SMD, how they’re used, and what that means for your manufacturing decisions.

What Are SMT and SMD? A Detailed Introduction for Electronics Professionals

SMT (Surface-Mount Technology) is a method used in electronics manufacturing where components are mounted directly onto the surface of a printed circuit board (PCB).

This process allows for smaller, lighter electronic devices, which is why it has become the industry standard.

SMD (Surface-Mount Device), on the other hand, are the actual electronic components designed to be mounted using the SMT process.

These components are typically smaller and more efficient than their through-hole counterparts, which allows for the production of denser and more complex circuit boards.

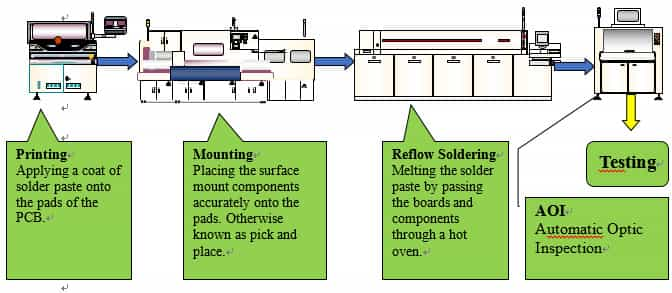

Understanding How SMT Works: A Step-by-Step Guide in Electronics Manufacturing

Surface-Mount Technology (SMT) involves a few key steps, including applying solder paste to the PCB, precisely placing Surface-Mount Devices (SMDs), and reflow soldering to secure the components. This process is faster and more automated than traditional through-hole methods, which makes it perfect for high-volume production.

Practical Example:

SMT is used in everything from smartphones to medical devices. By mounting SMDs directly onto the PCB, manufacturers can create compact, high-performance products with shorter production times.

SMD: The Essential Components Behind SMT

Surface-Mount Devices (SMDs) are the components used in SMT processes. These include resistors, capacitors, integrated circuits (ICs), and more, all designed to be mounted directly onto PCBs. Using SMDs allows for greater design flexibility and higher performance in electronic devices.

Practical Example:

SMDs are critical in consumer electronics, where space is at a premium. For example, in a smartphone, SMDs are used to create the dense, multifunctional circuits that make up the device’s motherboard.

SMT vs. SMD: Practical Implications in PCB Assembly

Choosing between SMT and SMD has big implications for PCB assembly:

- Compact Design: SMDs enable smaller, lighter PCB designs, which is important for devices like smartphones, wearables, and IoT devices.

- Efficiency: The SMT process is faster and less labor-intensive, which reduces manufacturing costs and increases production speed.

- Precision: SMDs require precise placement and advanced soldering techniques, which means you need sophisticated equipment and skilled technicians.

Advantages and Challenges of SMT and SMD

Advantages:

- Compact and Lightweight Designs: SMT allows for smaller, lighter products, which is important in today’s consumer electronics.

- Faster Production: SMT reduces the need for manual labor and can be highly automated, which speeds up production times.

- Cost Efficiency: Using less material and producing faster saves a lot of money.

- High Reliability: SMT connections are more robust, especially in environments with high vibration or mechanical stress.

Challenges:

- Heat Management: As PCBs get denser, managing heat becomes more challenging.

- Soldering Precision: The small size of SMDs requires extremely precise soldering, which often means you need advanced equipment and skilled operators.

- Inspection and Testing: The small size of SMDs makes inspection and testing more difficult, so you need specialized tools.

Comparing SMT vs. THT: When to Choose Each Technology

While SMT is the preferred method for modern, high-density electronics, Through-Hole Technology (THT) still has its place in certain applications:

SMT vs. THT: SMT allows components to be placed on both sides of a PCB and is suitable for high-density designs.

However, THT, which involves inserting component leads into drilled holes on the PCB, offers stronger mechanical bonds, making it ideal for components that require extra durability and stability, such as connectors or large transformers.

Comparison Table: SMT vs. THT

|

Feature |

SMT |

THT |

|

Component Size |

Smaller, more compact |

Larger, often bulkier |

|

PCB Sides Used |

Both sides |

Typically one side |

|

Assembly Speed |

Faster, automated |

Slower, often manual |

|

Mechanical Strength |

Lower, relies on solder joints |

Higher, with components securely anchored |

|

Applications |

High-density, consumer electronics |

Power electronics, high-stress environments |

Frequently Asked Questions (FAQ)

Yes, hybrid PCB designs can include both SMT and THT components. You can use SMT for high-density areas and THT for components that need extra mechanical support.

Common defects include tombstoning, solder bridging, and component misalignment. You can prevent these issues by applying solder paste correctly, placing components accurately, and using optimized reflow profiles.

People prefer SMT because it allows for smaller, more compact designs, faster production speeds, and more automation in manufacturing.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Knowing the difference between SMT and SMD is critical to optimizing your PCB designs and manufacturing processes. SMT is the process used to place and solder SMD components onto a PCB.

SMD refers to the components themselves. Understanding this distinction will help you make better decisions that improve your product designs and production efficiency.

Ready to upgrade your manufacturing process with SMT? Explore our comprehensive solutions tailored to your industry.

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

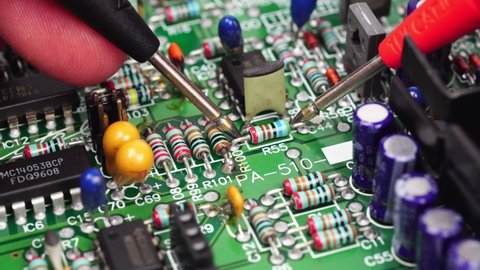

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!