Quick Leads

SMT vs. SMD (vs. THT): A Comprehensive Guide to PCB Assembly Techniques

In the world of electronics, you often hear the terms PCB and PCBA. While both play critical roles in electronic devices, the difference between the two can cause confusion, especially when choosing services. Knowing the difference between PCB and PCBA is essential for engineers and decision-makers looking for cost-effective, quality-driven solutions for their products.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

To fully understand their differences, let’s explore each term and the advantages of using PCBA over a bare PCB.

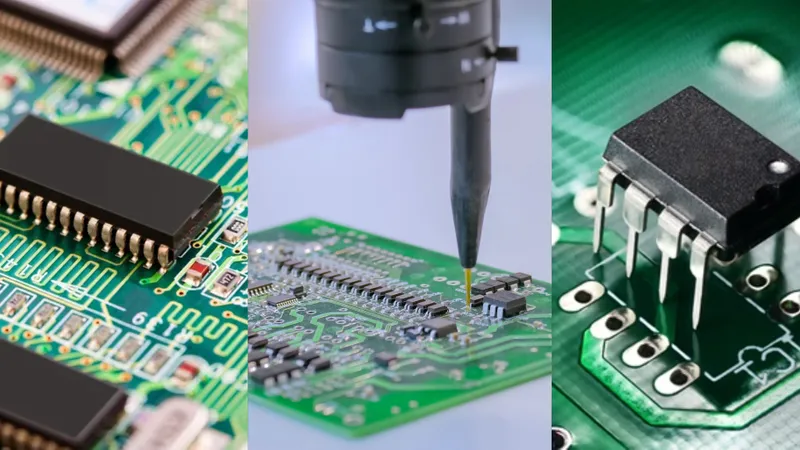

SMT (Surface Mount Technology):

Advantages of SMT:

-

High Efficiency in Production: SMT is great because it lets you use machines to build your boards. That means you don’t have to pay people to do it, and it goes a lot faster.

-

Reduced PCB Size: SMT is also cool because the parts are really small. That means you can put them really close together. That’s important for things like smartphones, where you need to fit a lot of stuff into a small space.

-

Lower Cost for Large Scale: If you’re making a lot of boards, SMT is cheaper.

Challenges of SMT:

-

Not Suitable for Power-Handling Components: SMT isn’t as good for big parts or parts that need to be really strong.

-

Complex Repair Process: If you mess up a part, it’s harder to fix it with SMT.

SMD (Surface Mount Device):

Relation to SMT:

Advantages of SMD:

-

Wide Variety: There are a ton of parts that you can use with SMT. That means you have a lot of choices when you’re designing your board.

-

High-Density Applications: SMD parts are small. That means you can fit a lot of them on your board. That’s important for things like phones, where you need to fit a lot of stuff into a small space.

Challenges of SMD:

-

Size Limitations: Not all components can be made small enough for SMT.

-

Requires Special Equipment: The small size of SMD components means specialized equipment is necessary for handling and mounting.

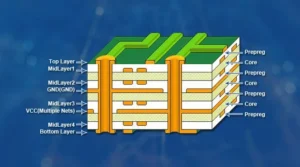

THT (Through-Hole Technology):

Advantages of THT:

-

Mechanical Strength: THT components have strong physical connections, making them ideal for larger or heavier components.

-

Better for High Power Applications: THT’s ability to handle higher currents makes it more suitable for industrial, automotive, and aerospace products.

Challenges of THT:

-

Slower and More Expensive: THT assembly is labor-intensive and slower due to the manual insertion process.

-

Requires More Space:THT parts are bigger, so you can’t put as many on your board.

Comparative Analysis: SMT vs. THT

When to Use SMT:

When to Use THT:

Feature | SMT | THT |

Assembly Speed | Fast (automated) | Slow (manual) |

Cost (large volume) | Lower | Higher |

Component Density | High | Lower |

Mechanical Strength | Lower | Higher |

Suitable for | Consumer electronics, telecommunications | Industrial, automotive, aerospace |

Power Handling | Lower | Higher |

Applications:

SMT Applications:

THT Applications:

Cost Implications:

SMT:

- Setup Costs: High initial setup due to automated equipment requirements, but efficient for large-scale production.

- Production Costs: Cost-effective for mass production due to automation, reduced labor, and faster assembly times.

THT:

- Setup Costs: Lower initial costs but can increase due to manual labor requirements.

- Production Costs: Higher for small to medium-scale production due to the slower assembly process and increased labor involvement.

Future Trends:

Conclusion:

👉 See how our Turnkey PCB Assembly can help »

Reference

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!