Quick Leads

SMT vs. THT: Why Combining Them in PCB Assembly Offers Speed, Reliability, and Performance

Introduction: Hybrid PCB Assembly for Cost and Performance Gains

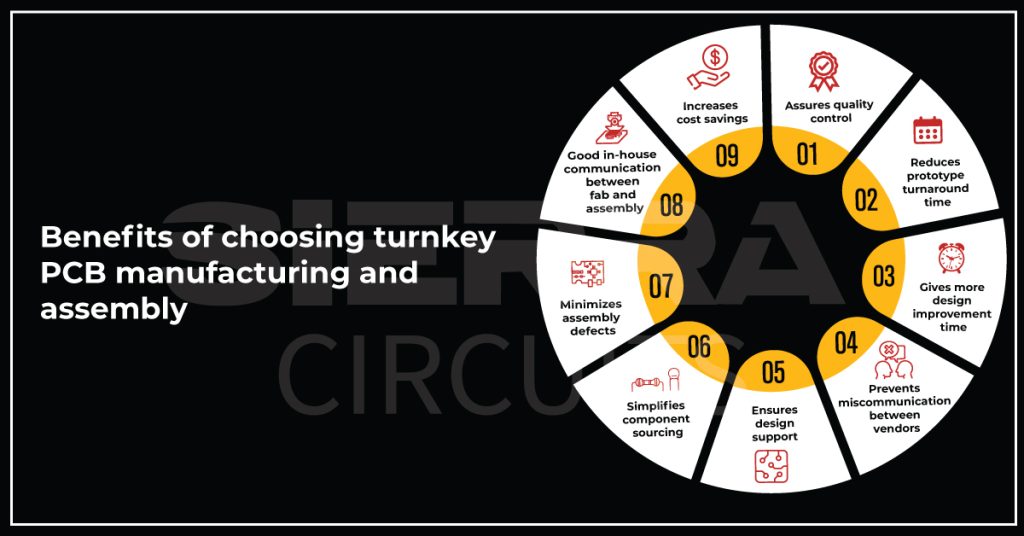

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Why Choose a Hybrid Approach: Combining SMT and THT for Cost and Performance Gains

When Does SMT Outperform THT? Faster, Smaller, and Cost-Effective Production

-

Space-saving design: SMT reduces the size of your PCB by 60-80%, which means you can pack more components into less space.

-

Automated assembly: You can place and solder components faster with automated machines.

-

Lower production costs: SMT reduces the amount of labor you need and speeds up your manufacturing.

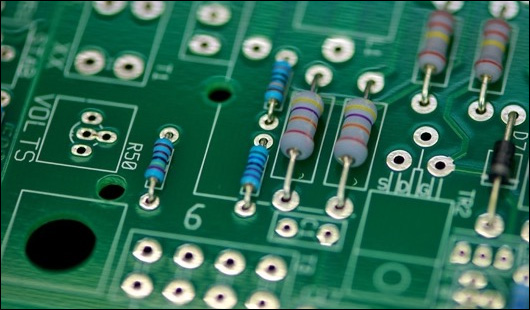

How THT Adds Mechanical Strength and Reliability to PCB Assembly

-

Mechanical strength: Leads that go through the board make stronger physical connections.

-

Durability: Good for environments with lots of vibration, like cars and airplanes.

-

Prototyping flexibility: Lets engineers swap parts easily when they’re testing.

How Combining SMT and THT Unlocks the Best Performance and Reliability

-

SMT handles smaller, complex components, This makes your design light and saves space.

-

THT provides mechanical support for larger parts that need more stability.

Comparison Table: SMT vs. THT vs. Hybrid PCB Assembly

|

Feature |

SMT |

THT |

Hybrid Assembly |

|

Assembly Speed |

High (automated) |

Low (manual/semi-automated) |

Balanced: SMT for speed, THT for durability |

|

Cost Efficiency |

Lower production costs |

Higher labor costs |

Optimized: Use SMT with selective THT |

|

Reliability |

Moderate |

High |

High: SMT for density, THT for key components |

|

Best Applications |

Consumer electronics, IoT |

Automotive, aerospace |

Complex boards needing both speed and stability |

When to Use Both SMT and THT in PCB Manufacturing

-

Power Supplies: SMT for control circuits, THT for transformers and large capacitors.

-

Automotive Electronics: SMT offers compact designs, while THT supports robust connectors.

-

Industrial Equipment: SMT enables automation, and THT provides durability under mechanical stress.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

Using both technologies lets you make your design small (with SMT) and tough (with THT). You get the best of both worlds.

Not necessarily—SMT reduces labor costs, while THT provides durability where needed. You only use THT for the parts that need to be extra strong. That way, you keep your costs down.

Key Takeaways

-

Hybrid PCB assembly combines the best of both worlds: You get small size and fast production with SMT, and you get the parts that last a long time with THT.

-

Use SMT for small, intricate components and THT for larger parts that need mechanical support.

-

This approach ensures scalability and durability across industries like automotive, aerospace, and consumer electronics.

Conclusion

Request for Quote

RECENT POSTS

Quick Turn Turnkey PCB Assembly: Fast Quotes, Faster Prototypes, Lower Risk

Quick turn turnkey PCB assembly for engineers who need fast quotes, reliable component sourcing, controlled SMT/DIP processes, and verified prototypes. Reduce risk, avoid platform pitfalls, and move from design to working boards faster.

IC Boards Explained: Applications, Layout Tips, and Assembly Services

Discover what IC boards are, how they’re used in modern electronics, and how to design them effectively. Learn layout tips and explore expert IC board assembly services for faster production.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!