Quick Leads

10 Essential Steps in PCB Assembly for Industry Professionals

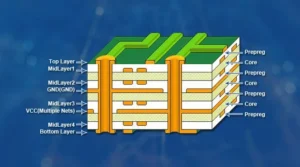

Putting together a Printed Circuit Board (PCB) is a big deal in electronics manufacturing. If you’re in the industry, you need to know how to do it right so you can make high-quality, cost-effective products.

Whether you’re an electrical engineer, procurement manager, or technical buyer, knowing how to do PCB assembly gives you the power to make decisions that affect the quality and time it takes to get your product to market.

Here’s a step-by-step guide to the 10 most important steps in PCB assembly. We’re going to focus on quality control, efficiency, and turnkey solutions.

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

PCB assembly involves several stages that ensure components are accurately placed and soldered to create a functional circuit. The 10 essential steps in PCB assembly are as follows:

1. Solder Paste Application

The first step in the assembly process is putting solder paste on the PCB. We use a stainless-steel stencil to put paste in specific spots where we’re going to put parts.

This step is super important because it makes sure we solder everything right later on. If we don’t put the solder paste on right, the connection between the parts and the PCB could be messed up.

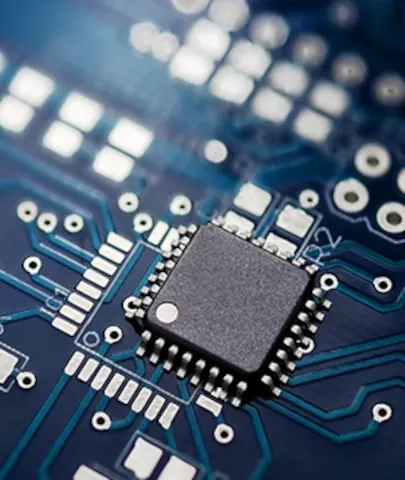

2. Pick and Place Components

We use machines to pick up surface mount parts from reels or trays and put them on the PCB.

These machines are fast and super accurate. For people who are in charge of making PCBs, this step makes sure the parts are in the right place, which helps prevent defects and makes more good parts.

3. Reflow Soldering

After we put the parts on, the board goes through a reflow oven. The oven melts the solder paste, which makes a permanent electrical connection between the parts and the board.

Reflow soldering is a big deal because we have to control the temperature just right to make sure we don’t mess up the parts that are really sensitive.

4. Inspection and Quality Control

At this point, we check the PCB to make sure everything is right. We can do this by looking at the board or using a machine called an Automated Optical Inspection (AOI) system.

AOI systems use cameras that can see really well to find things like parts that aren’t in the right place, bad soldering, or parts that are missing. This step is critical to ensure that the assembled PCB meets industry quality standards before moving to further processing.

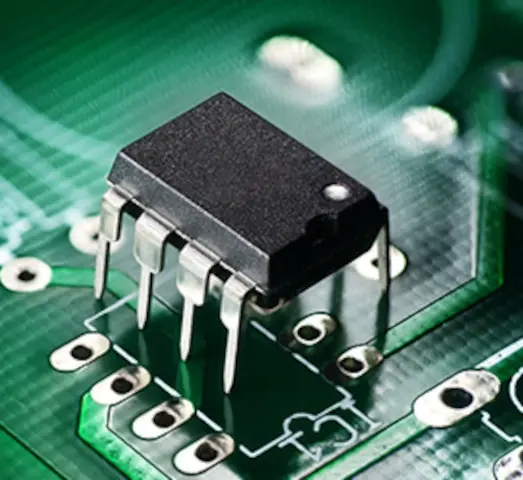

5. Through-Hole Component Insertion

Most of the time, we use surface-mount technology (SMT) to put parts on the board.

But some parts, like connectors and capacitors, still need to be put on the board with through-hole mounting. We put these parts in holes that are already in the board and then solder them by hand or with a machine that solders everything at once.

6. Wave Soldering

We use wave soldering for through-hole parts. We run the PCB over a wave of melted solder, which solders the leads of the parts to the board.

This is a good way to make sure the parts are soldered right and stay on the board. It’s really important to do wave soldering the right way so the parts are connected well and won’t come off.

7. Final Inspection and Functional Testing

After we solder all the parts, we check the PCB one last time and test it to make sure it works right. This is where we make sure the PCB not only looks right but also does what it’s supposed to do.

We turn the board on and test it(Functional testing) to see if it works like it should in the real world. This is a big deal because it helps us catch problems before they get to the final product

8. Conformal Coating and Cleaning

Sometimes we put a protective coating on the PCB to keep it safe from things like dust, water, and really hot or cold temperatures.

We also clean the board to get rid of any leftover stuff that could mess up how the board works.

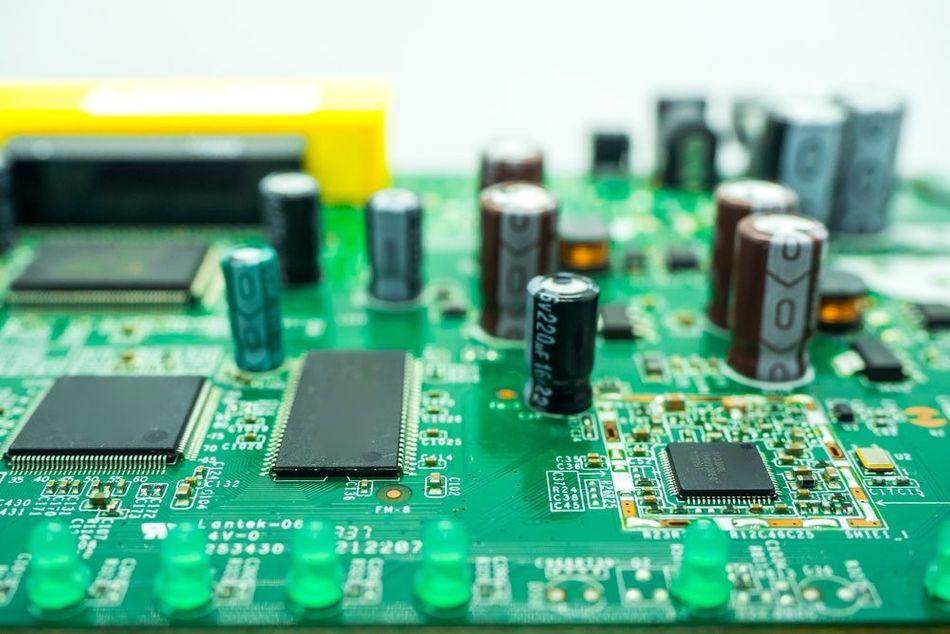

9. Assembly of Final Product

After we check and test the PCB, we put it in the final product. This could mean putting the board in a case, connecting it to other parts, and getting it ready to send out.

This is where turnkey PCB assembly is really helpful because it makes sure we put the board together fast and right every time.

10. Packaging and Delivery

Finally, we pack up the PCB or electronic product and get it ready to send out. We make sure we don’t have a minimum order quantity (MOQ), give you a quote fast, and get it to you quickly so you can meet your deadlines without having to worry about quality.

For people who are in charge of making stuff, this is a big deal because it helps you stay ahead of the competition.

Why Quality Control is Key in PCB Assembly?

Quality control is built into every step of the PCB assembly process, from putting the solder paste on to testing the board. If you’re in the electronics business, you want to make sure you watch every step to keep defects down, cut rework costs, and make sure your product works right.

Things like automated optical inspection, wave soldering control, and testing the board are all important to make sure you make good electronics that meet the standards.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliver

Why Choose Turnkey PCB Assembly?

If you choose a turnkey PCB assembly service, you get a lot of good stuff, especially if you want to put stuff together fast and right without having to order a certain amount. Turnkey solutions make it easy to put things together, and you get stuff like:

No MOQ: Ideal for prototyping or small batch production.

Fast Quotes: Receive detailed quotes quickly to ensure timely decision-making.

- Rapid Delivery: Short lead times mean faster time-to-market for your products.

Outsourcing to a professional electronic manufacturing services (EMS) provider that specializes in turnkey PCB assembly ensures your project is handled by experts who prioritize quality, speed, and cost-efficiency.

Summary

PCB assembly is a complex, multi-step process that requires precision and attention to detail at every stage.

From putting the solder paste on to testing the board, everything is important to make sure your product works right and is good quality. If you hire a turnkey PCB assembly service, you can make sure you put your board together fast, right, and the way it’s supposed to be.

If you need a PCB put together fast and right, get in touch with us today and see the difference in professional PCB assembly services.

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!