Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

🟢 Introduction to Surface Mount Technology (SMT)

In modern electronics manufacturing, the demand for speed, miniaturization, and performance makes traditional PCB assembly methods feel outdated. Through-hole assembly, once the industry standard, can no longer keep up with today’s complex, compact designs.

Surface Mount Technology (SMT) emerged as the industry’s answer — enabling high-speed, automated assembly of components directly onto the surface of PCBs. This shift revolutionized electronic production.

SMT is often confused with SMD (Surface Mount Device) — the component type. While SMT refers to the assembly method, SMDs are the parts placed using SMT.

Over time, SMT has become the default approach in industries like automotive, telecom, medical devices, and consumer electronics — thanks to its compact layout, lower cost, and automation-friendliness. For a detailed comparison between SMT, SMD, and traditional through-hole technology (THT), check out our comprehensive guide to PCB assembly techniques. Learn more about the history and definition of Surface Mount Technology (SMT).

🟡 SMT Process in PCB Manufacturing: How It Works

The SMT workflow begins long before the assembly line starts moving. A successful build starts with thoughtful design for manufacturability (DFM), ensuring the pad layout and stencil apertures are optimized for consistent soldering.

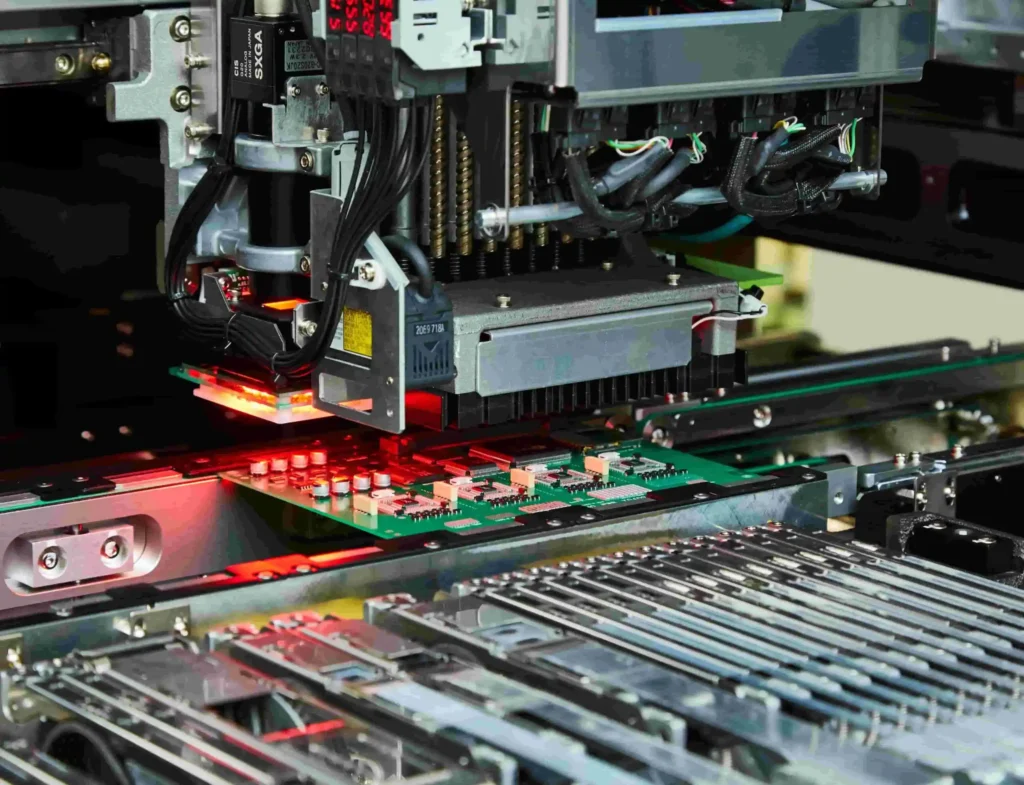

Pick-and-place machines play a central role in this process, accurately positioning thousands of components per hour. In 2026, many factories now operate with automated SMT lines, improving efficiency and traceability. Explore in detail how SMT pick-and-place machines work and what makes them essential in PCB production lines.

Soldering is typically done via reflow ovens, though wave soldering may still be used in mixed-technology boards. For double-sided PCBs, SMT components are placed on both sides and soldered in separate passes.

By integrating advanced software and MES systems, SMT lines today achieve remarkable throughput with fewer errors, helping manufacturers stay competitive in a fast-moving market.

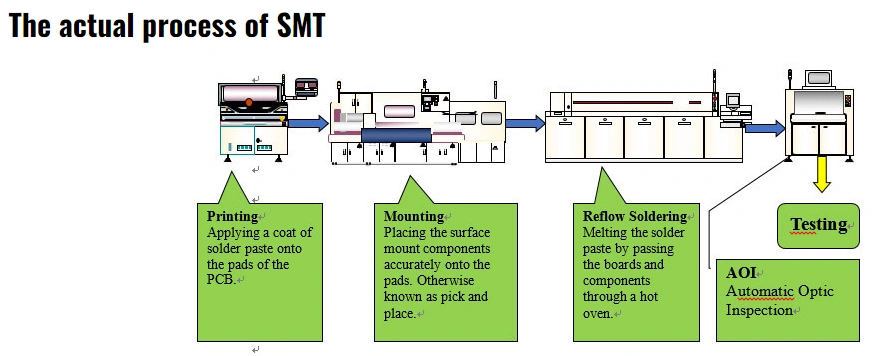

🔹 Step-by-Step SMT Assembly Process

Here’s how a typical SMT PCB assembly process unfolds:

Step 1: Solder Paste Printing

A stainless-steel stencil is used to deposit solder paste onto the PCB pads. The paste must be evenly applied — too much causes bridging, too little leads to cold joints.

Step 2: Component Placement

Using CAD-generated pick files, high-speed machines place each surface mount device in its precise location. Placement accuracy now reaches ±30 microns in leading factories.

Step 3: Reflow Soldering

The PCB enters a controlled reflow oven, passing through multiple temperature zones. The paste melts, forming strong electrical connections before cooling.To learn how to optimize thermal profiles and avoid common soldering defects, visit our expert guide on SMT reflow soldering tips.

Step 4: Inspection and Testing

Modern SMT production includes AOI (Automated Optical Inspection), X-ray inspection for hidden solder joints, and In-Circuit Testing (ICT) to ensure functional integrity.

Common Challenges

Operators often deal with defects like tombstoning, skewing, or voiding. These are minimized with proper thermal profiling, stencil design, and solder paste selection.

For beginners or prototyping teams, understanding these stages is critical to optimizing the final yield and ensuring reliable board performance.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

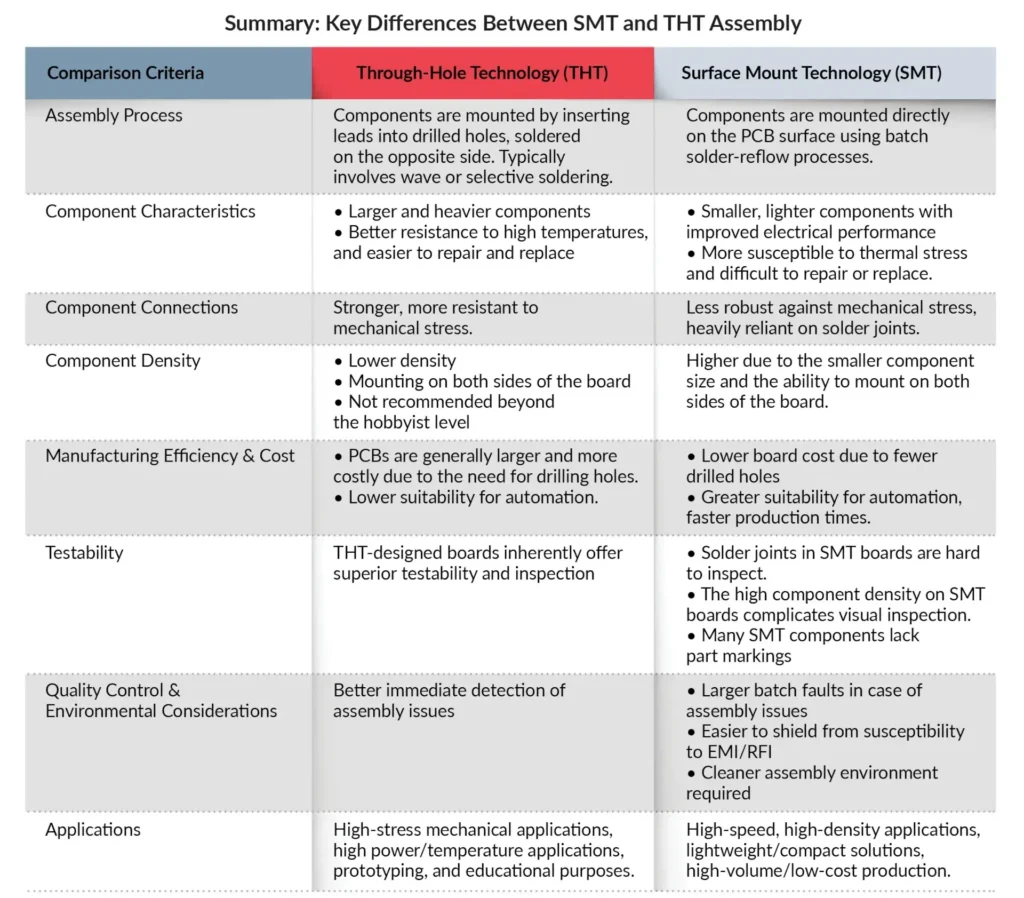

🔹 Surface Mount vs Through-Hole: Which One Is Better?

Both assembly methods have their place in modern electronics, but SMT offers undeniable advantages:

Higher density: SMT supports compact, miniaturized PCB layouts

Faster assembly: Automated machines drastically reduce production time

Lower cost: Especially for mid-to-high volume production runs

In contrast, through-hole technology still plays a role in:

High-current or mechanically stressed components

Socketed parts or connectors requiring strong physical retention

Products requiring frequent manual rework

In some cases, a hybrid PCB assembly approach is best — using SMT for logic and signal processing and through-hole for connectors or power. If you’re considering a hybrid approach that combines SMT and through-hole for your project, read our guide on overcoming challenges in hybrid PCB assembly.

🔹SMT Technician Skills & Job Roles in 2026

With increasing automation, the role of the SMT technician is evolving. The most in-demand skills today include:

Manual soldering and rework expertise

Experience with AOI machines and X-ray systems

Schematic reading and fault isolation

Machine programming and MES integration

Entry-level operators may start with material handling or line loading, but as lines become smarter, technicians must adapt to Industry 4.0 tools, such as machine learning diagnostics or predictive maintenance dashboards.

In many factories, there’s now a continuous feedback loop between design and production — enabling smarter revisions, fewer defects, and better end-product quality.

🔹Key Advantages of SMT in Modern Electronics

SMT offers several compelling advantages that align with 2026’s product demands:

Smaller, lighter PCBs suited for wearables and portable tech

Higher reliability in signal integrity and performance

Faster production cycles through full automation

Cost reduction over traditional through-hole assembly

The rise of miniaturized electronics and high-frequency PCBs in RF applications has pushed SMT to the forefront. In IoT and medical device sectors, space savings and reliability are critical — making SMT the only viable solution.

🔹 Outsourcing SMT PCB Assembly to China: What to Know

Outsourcing to China offers cost benefits but also raises concerns:

Quality assurance challenges

Communication gaps

Intellectual property protection

Prototyping delays

That’s why at Unit Circuits, we’ve built our model around eliminating these barriers. Our turnkey SMT PCB assembly services include:

English-speaking engineering support

Certified production (ISO, IPC Class 2/3)

DFM validation and prototype feedback

Transparent pricing and logistics management

When comparing providers in China vs the US or EU, what matters most is not geography — it’s responsiveness, process transparency, and support. Our factory adheres to IPC Class 2/3 standards to ensure consistent quality in every assembly.

🔹Low-Volume SMT Assembly: Solutions for Startups

Startups often struggle with low-volume PCB manufacturing because:

Tooling costs are too high for small runs

Component sourcing can be inefficient

Many factories prioritize large batches

Our approach at Unit Circuits solves this by offering:

Flexible NPI (New Product Introduction) lines

Fast setup and minimal MOQ

In-house sourcing and on-demand stencil manufacturing

Real-time feedback from our process engineers

This enables startups to iterate quickly, improve quality with each build, and scale confidently. We’ve supported dozens of hardware teams with prototype-to-production transitions in under 6 weeks.

🔹 Turnkey SMT Assembly Explained

In PCB manufacturing, turnkey means the entire process — from component sourcing to testing — is handled by one provider.

Our turnkey SMT services include:

DFM and BOM validation

Supplier sourcing and price negotiation

SMT assembly using modern equipment

Post-assembly inspection and function testing

Packaging and global shipping

This reduces project management overhead for engineers and speeds up your go-to-market timeline. Turnkey solutions are particularly useful for:

Product teams with limited in-house resources

Startups scaling quickly

Teams needing global logistics or multi-site delivery

🔹2026 SMT Trends: What’s Next in Surface Mount Technology?

SMT manufacturing is advancing rapidly. In 2026, the key trends include:

AI-assisted defect detection

Smart factory integration with MES and ERP systems

Predictive maintenance to reduce downtime

Flexible substrates and foldable PCB tech

3D AOI and inline SPC tracking

Engineers designing for the next generation must consider automation compatibility, thermal constraints, and real-time traceability early in their BOM and layout decisions.

FAQs

1. What is SMT Surface Mount Technology in simple terms?

Surface Mount Technology (SMT) is a method where electronic components are mounted directly onto the surface of a printed circuit board (PCB), without drilling holes. It enables faster, automated assembly, making it ideal for compact designs used in smartphones, wearables, and modern electronics. SMT has largely replaced traditional through-hole methods in high-volume production.

2. What mounting technology is used for small, high-density PCB designs?

For high-density and miniaturized PCB designs, SMT (Surface Mount Technology) is the preferred mounting method. SMT allows precise placement of tiny components (SMDs) using automated pick-and-place machines, making it ideal for IoT, medical, and consumer electronics. It reduces size, cost, and weight compared to older through-hole technology.

3. What is the biggest benefit of using SMT in PCB assembly?

The biggest benefit of SMT in PCB assembly is automation and compact design. SMT enables faster production with smaller components, allowing for more functionality in less space. This boosts production speed and reduces costs—critical for competitive electronics manufacturing. It’s especially beneficial in high-frequency and portable device applications.

4. What does SMT assembly include from start to finish?

SMT assembly includes several steps: solder paste printing, component placement, reflow soldering, inspection (AOI/X-ray), and testing. It’s a fully automated process that transforms bare PCBs into functional electronic assemblies. For turnkey services, SMT assembly may also include component sourcing, DFM review, and packaging, streamlining production for OEMs.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion: Is SMT Right for Your Next Project?

If your next hardware project requires precision, speed, and scalable manufacturing, then SMT is the right choice.

Choosing a reliable assembly partner can accelerate prototyping, reduce defects, and simplify the path from concept to market.

📩 Want to get started? Request a Free Quote from Unit Circuits.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!