Quick Leads

Top Methods to Detect and Prevent Soldering Defects in PCB Assembly

Introduction

Common PCB Soldering Defects and How to Detect Them

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

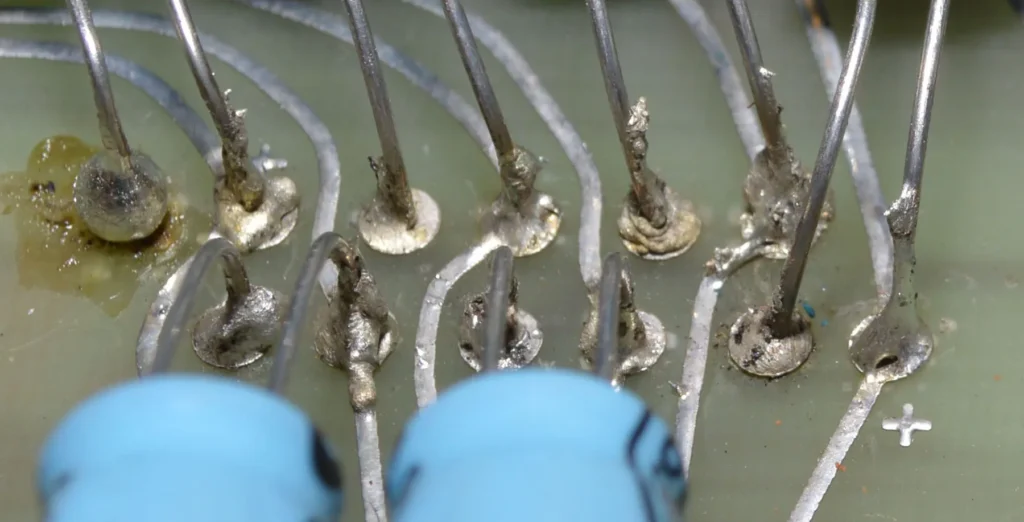

1.Cold Solder Joints

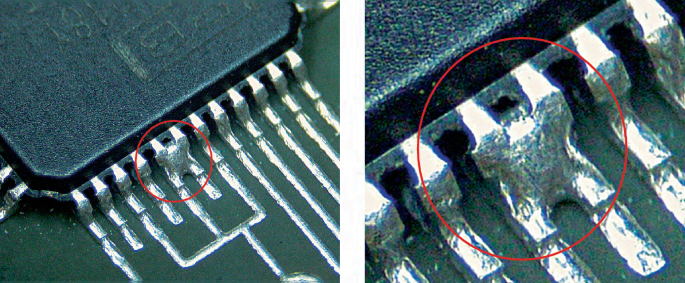

2.Solder Bridges

3.Insufficient Solder

4.Solder Balling

Solder Balling: During reflow soldering, small solder balls can form if you don’t apply the paste correctly or control the temperature properly. These balls can cause shorts if they stay on the board.

Tip: After reflow, check the board to make sure there aren’t any stray solder balls that could create shorts between components.

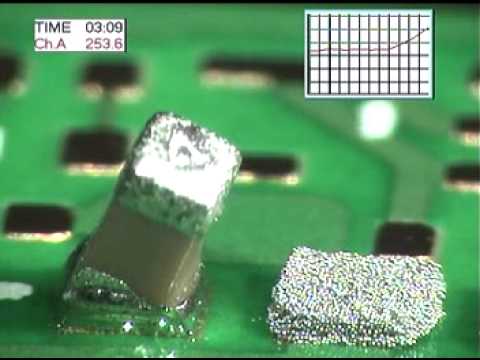

5.Tombstoning

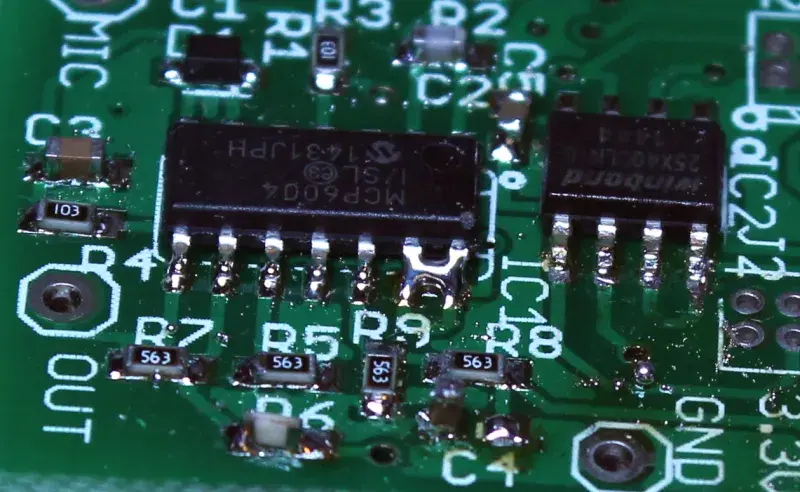

PCB Solder Defect Detection Methods

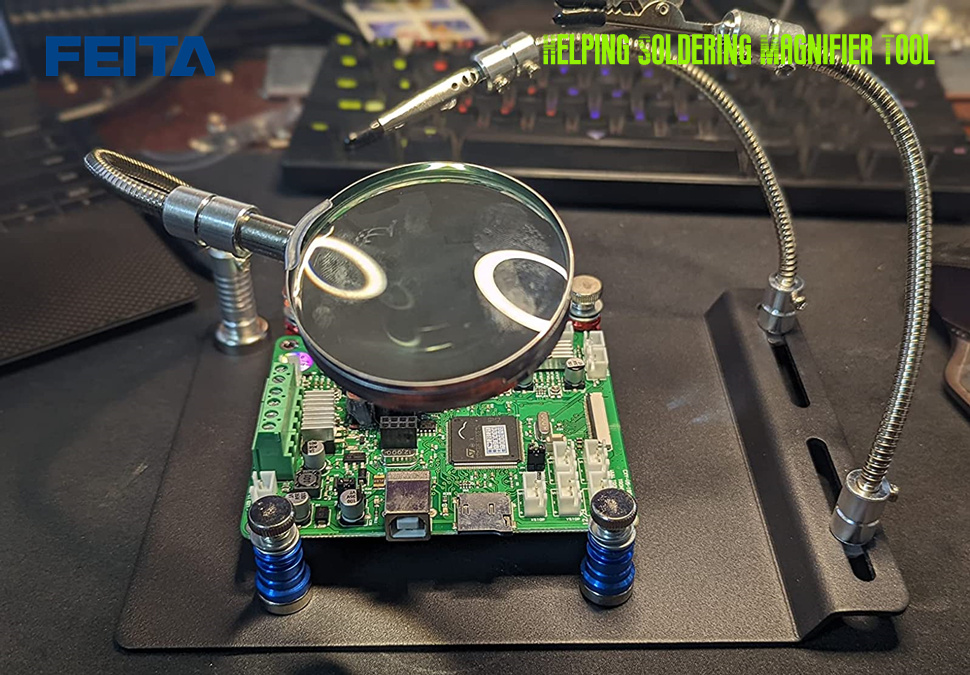

1.Visual Inspection

- Use magnification (at least 5x–10x) to closely inspect solder joints.

- Focus on areas with dense components or fine-pitch leads.

- Look for irregularities in solder flow, dull or grainy joints, and any signs of bridges or misalignment.

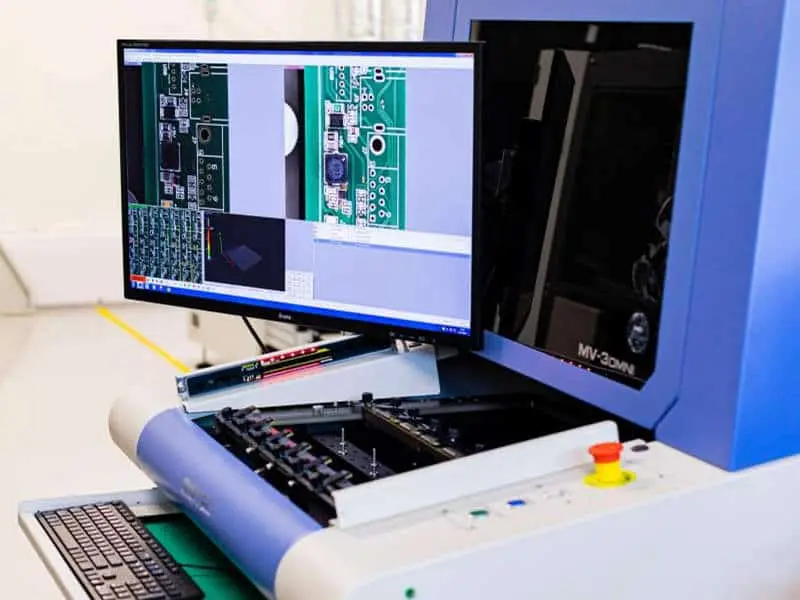

2.Automated Optical Inspection (AOI)

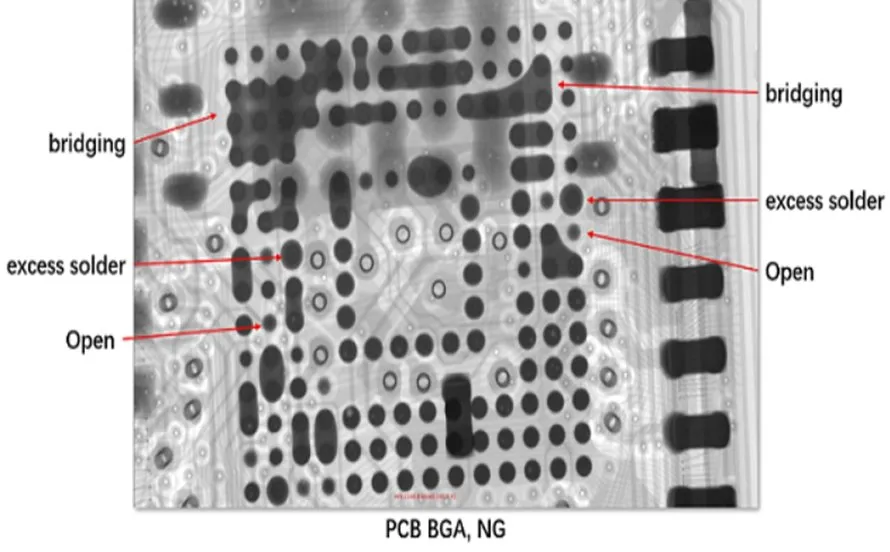

3. X-ray Inspection

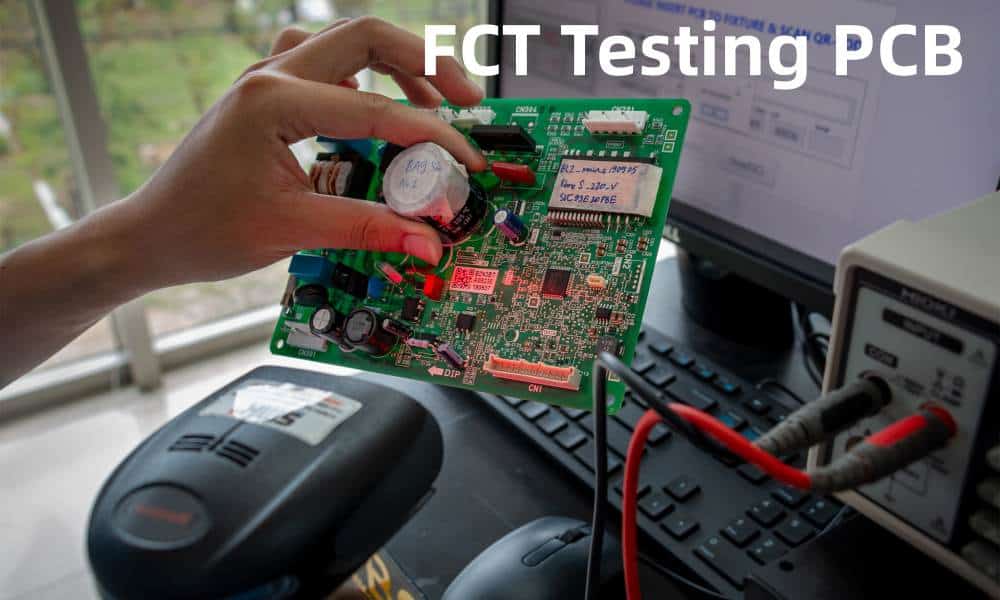

4. Functional Testing

Best Practices for Preventing PCB Soldering Defects

Proper Soldering Techniques

Make sure your techs know how to apply the right amount of solder and heat. If they don’t use enough heat, they’ll get cold solder joints. If they use too much solder, they’ll get bridges.- Tip: Keep up with new processes or materials by reviewing and updating your soldering techniques.

Maintain Optimal Reflow Temperature Profiles

You have to control the temperature in your reflow ovens to avoid defects like tombstoning and solder balling.- How to Adjust Temperature Profile to Avoid Tombstoning:

- Use a gradual temperature ramp-up.

- Ensure the preheating stage is uniform across the PCB.

- Control the cooling stage to avoid sudden drops in temperature

- Use High-Quality Soldering MaterialsUse good solder paste, flux, and clean PCBs to minimize defects. When you use cheap materials, you get more defects during reflow or wave soldering.

- Regular Equipment MaintenanceKeep your soldering equipment, including reflow ovens and wave solder machines, in good shape. Tip: Schedule regular maintenance checks to recalibrate temperature settings and check machine accuracy.

Frequently Asked Questions (FAQ)

The most common defect is cold solder joints. That happens when you don’t use enough heat when you solder, and it causes weak electrical connections.

Use good soldering techniques, control your temperature profiles during reflow, and use good materials to avoid common defects like tombstoning and solder bridges.

Calibrate your AOI and X-ray machines every quarter to make sure they can find hidden or surface-level defects.

The best way to find hidden solder defects, especially in BGAs where you can’t see the joints, is to use X-ray inspection.

You can use visual inspection or AOI to find surface-level defects. For hidden solder joints, use X-ray inspection. 容

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

🔧 Want to avoid these manufacturing issues with a trusted partner?

👉 See how our Turnkey PCB Assembly can help »

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select the right transformer for SMPS, IoT, or relay control. Start designing smarter today.

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and delivery—and how turnkey EMS solutions protect your product and bottom line.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!