Quick Leads

Why is Potting Adhesive Essential for Electronics?

Key Functions of Electronic Potting Adhesives

Environmental Protection

- Moisture: Prevents water ingress, which can cause short circuits and corrosion.

- Chemical Exposure: Blocks out corrosive agents like sulfur or chlorine, which degrade components over time.

- Dust and Debris: Seals components from foreign particles that can interfere with their performance.

Mechanical Stress Relief

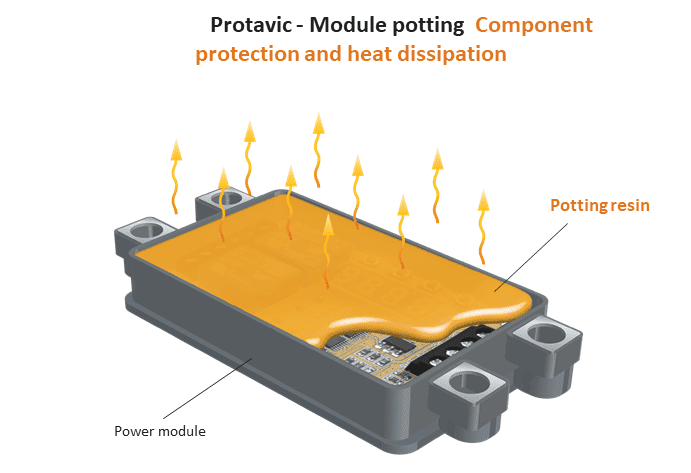

Thermal Management

Electrical Insulation

Enhanced Durability

Customization for Specific Applications

What is the Purpose of Potting in Electronics?

What are Adhesives Used for in Electronics?

What is the Best Potting Material for Electronics in Harsh Environments?

What is Adhesive Potting and How Does it Protect Electronics?

For more information, visit below:

Frequently Asked Questions (FAQ)

Potting adhesives protect your sensitive electronic components from the environment, mechanical stresses, and thermal management challenges. They also enhance electrical insulation to ensure safe, long-lasting operation.

You usually put potting compounds on by filling or encapsulating the whole electronic assembly with a solid or gelatinous compound. You can automate the process for high-volume manufacturing or do it by hand for smaller applications.

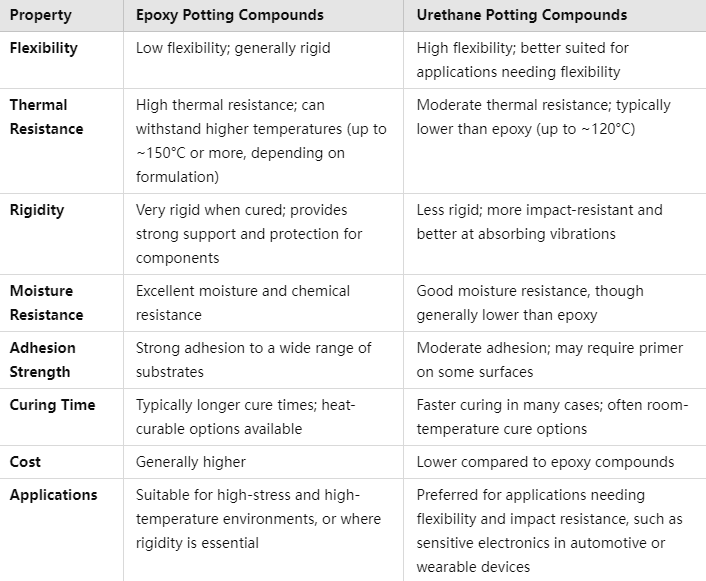

Common potting materials are epoxy, polyurethane, and silicone-based compounds. Each material has its strengths, like better thermal management, flexibility, or chemical resistance, making them perfect for specific applications.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!