Quick Leads-PCBA

🟢 Introduction: What Is Box Build Assembly in Electronics Manufacturing?

In electronics manufacturing, delivering a fully functional product goes far beyond PCB assembly. Many OEMs struggle with coordinating multiple vendors, managing supply chains, and ensuring the final product passes inspection. That’s where box build assembly comes in—offering a streamlined, turnkey solution from boards to fully enclosed systems.

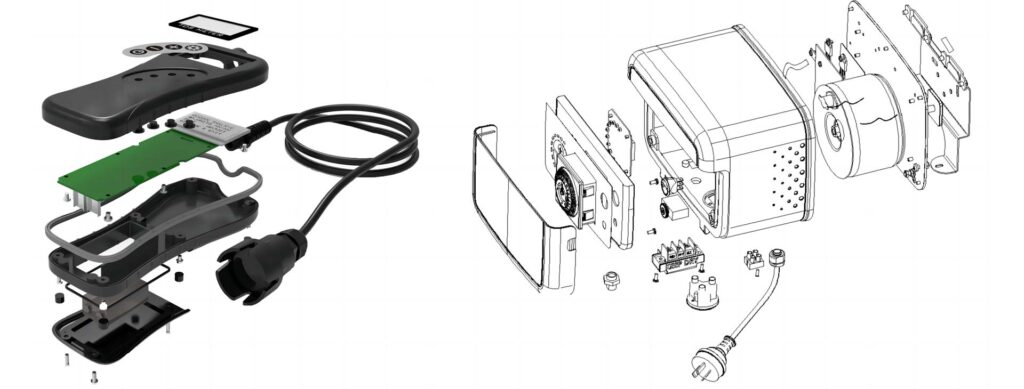

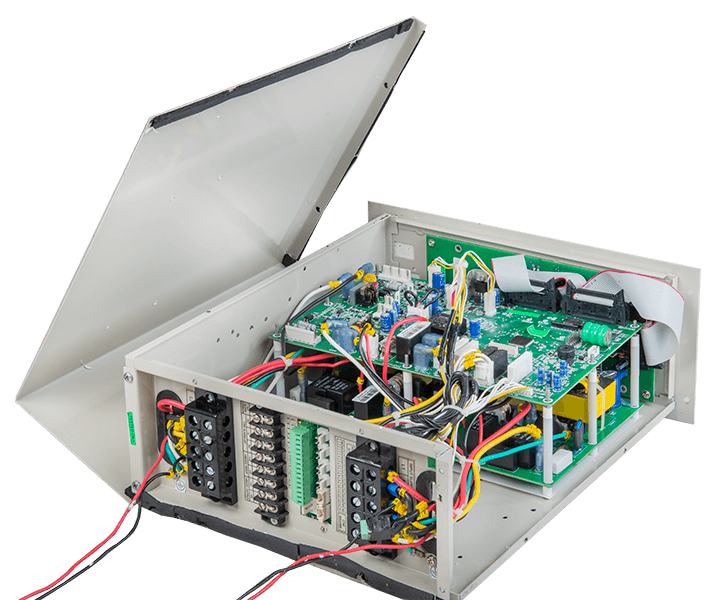

Box build assembly refers to the complete integration of a printed circuit board (PCB) with mechanical components such as enclosures, wiring, cable harnesses, and other subsystems into a final, fully functional product. It typically includes system integration, firmware loading, and testing—delivering a plug-and-play solution ready for deployment.

Let’s take a closer look at what box build assembly includes, how it works, and why it’s a game-changer for OEMs looking for speed, scalability, and reliability.

What is box build in electronics?

What is box build in electronics?

Box build in electronics refers to the full assembly of a product that includes not only the PCB but also its enclosure, wiring, connectors, cable harnesses, and sometimes firmware and final packaging. It’s essentially the process of taking a bare functional PCB and integrating it into its mechanical housing—as described in Cadence’s guide to box build assembly.

This level of assembly ensures that when the unit leaves the manufacturing floor, it’s ready for immediate use or distribution, eliminating the need for additional touchpoints or vendors.

🔹What is the box build assembly process?

The box build assembly process is a multi-stage, highly coordinated effort that typically involves the following steps:

Procurement & BOM Management: Source all electrical, mechanical, and enclosure components based on the client’s bill of materials (BOM).Effective box build assembly starts with sourcing and accurate BOM management, ensuring all required components are accounted for early in the process.

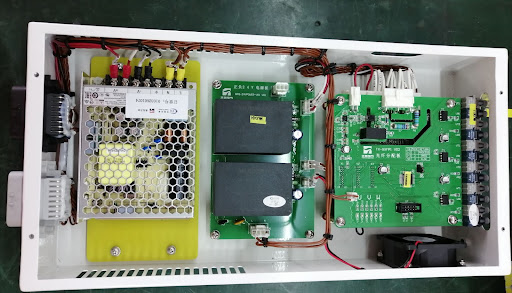

PCB Assembly: Fabrication and population of the printed circuit board (surface-mount, through-hole, or mixed).

Mechanical Integration: Installation of the PCB into an enclosure along with mechanical hardware (standoffs, gaskets, etc.)

Cable and Wire Harness Assembly: Routing and soldering cables, connectors, and internal wiring to specifications.

Firmware Installation (if required): Programming MCUs, EEPROMs, or any smart component.

Functional Testing in Box Build: Performing full system checks to verify power, I/O, and software functionality.

Final Assembly & Packaging: Sealing, labeling, and packing for shipment.

Each stage must follow RoHS compliance and IPC standards to ensure the product’s longevity, safety, and global compatibility.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

🔍What is the difference between PCB assembly and box build?

The distinction between PCB assembly and box build is significant:

| Feature | PCB Assembly | Box Build Assembly |

|---|---|---|

| Scope | Just the board | Full product enclosure |

| Includes Enclosures? | ❌ No | ✅ Yes |

| Cable Harness & Wiring | ❌ | ✅ |

| Software/Firmware Loading | ❌ | ✅ |

| Testing | Basic electrical testing | Full functional & system testing |

In short, PCB assembly is a subset of the broader box build process.

What is included in box build services?

What is included in box build services?

Box build services vary, but most advanced EMS providers offer:

Custom mechanical assembly

Electronic enclosure assembly

Cable and wire harness integration

Firmware and software installation

Functional and environmental testing

Labeling, serialization, and packaging

Your partner’s ability to manage the full chain—from design to delivery—will impact quality, lead time, and cost control.

How turnkey box build assembly services reduce time-to-market

How turnkey box build assembly services reduce time-to-market

Turnkey services simplify your supply chain. You provide the design and BOM; the manufacturer handles everything else—sourcing, assembly, testing, and shipping. This model:

Reduces vendor communication overhead

Consolidates billing and logistics

Accelerates development cycles

Improves design for manufacturability (DFM)

UnitCircuits offers full turnkey box build assembly services, including BOM review, lead-free soldering, and RoHS-compliant practices that meet EU directives.If you’re looking for an efficient and scalable manufacturing model, turnkey services eliminate multi-vendor coordination and speed up delivery. For a deeper dive into how this approach can transform your operations, explore our full guide on turnkey PCB assembly services

📦 Low volume box build assembly: Is it cost-effective?

Yes—especially for prototyping, startups, and industrial applications with highly customized units. Key advantages include:

Rapid iteration and testing cycles

Lower MOQ requirements

Flexibility in component sourcing

Agile response to design changes

With our low volume box build assembly services, you won’t be forced into high-volume contracts just to access quality and speed.

🌏 Benefits of box build assembly in China for OEMs

Choosing box build assembly in China offers:

Access to a wider supply chain

Lower labor and production costs

Proximity to component manufacturers

Scalability for high or low volumes

UnitCircuits’ Shenzhen-based factory supports RoHS-compliant PCB assembly from China with a strong emphasis on sustainable electronics manufacturing and export readiness.

⚡ Fast box build assembly services: What to look for?

To ensure fast delivery without compromising quality, look for:

In-house PCB and enclosure capabilities

On-site testing and QC procedures

Dedicated engineering support

Established component supplier relationships

Our team offers fast box build assembly services with lead times as low as 7 working days for qualified projects.

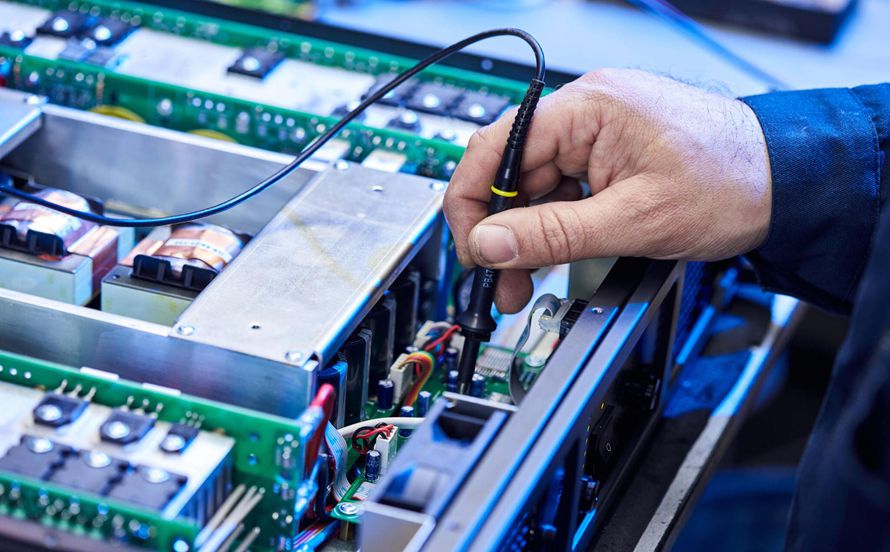

🧩 How box build assembly with testing ensures reliability

Testing is the core of any quality box build project. Our test protocols include:

In-circuit testing (ICT)

Functional testing (FCT)

Burn-in and environmental stress screening

Visual and AOI inspection

This ensures that your final product works exactly as intended—before it reaches your customer.

Testing in box build isn’t just about basic electrical checks—it’s about validating the entire system. Learn about advanced techniques like burn-in, FCT, and in-circuit testing in our guide to PCB testing methods

🛠️ Custom box build assembly for OEMs: Design to delivery

Each OEM has unique needs. We specialize in custom box build assembly for OEMs across:

Industrial automation

Medical electronics

Smart home devices

Energy management systems

We support the full journey: DFM, prototyping, pilot runs, and mass production—with all regulatory requirements handled in-house.

Successful custom builds depend on early collaboration between electronics and mechanical engineers through the integration of ECAD and MCAD tools

OEMs often underestimate how purchasing decisions impact build success. From BOM accuracy to quality standards, it’s critical to plan ahead. Don’t miss our expert advice on the 6 key elements you should never ignore when purchasing PCBA.

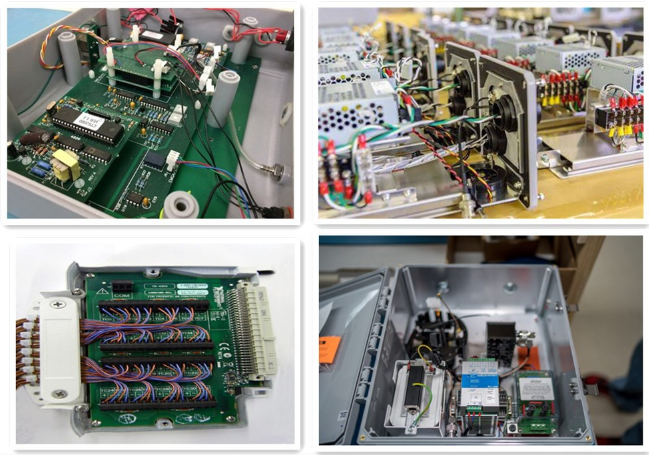

🖥️ Electronics box build solutions for industrial control systems

Industrial control systems require:

High EMI shielding

Redundant wiring

Heavy-duty enclosures

Strict compliance with safety standards

Our electronics box build solutions are tailored for industrial markets, offering rugged assemblies that withstand harsh environments and extended use.

⚖️ Box build vs PCB assembly: Which one do you need?

If you only need the circuit board, go with PCB assembly. But if you need:

An enclosed, tested, and ready-to-deploy device

Simplified sourcing and reduced vendor management

Shorter product development cycles

…then box build assembly is the smarter choice.

Let us help you evaluate which model is right for your next product.

FAQs

1. What is final assembly in box build?

Final assembly in box build refers to the last stage of the manufacturing process, where all internal components—like PCBs, wiring, and firmware—are enclosed, labeled, and prepared for shipment. This stage includes full system checks and packaging, ensuring the product is ready for end-use. Choosing a partner that handles final assembly box build guarantees consistent quality and reduces your time-to-market.

2. What is turnkey PCB assembly and how does it differ from box build?

Turnkey PCB assembly means the manufacturer handles every step of PCB production—from sourcing components to final board testing. However, it stops at the board level. In contrast, turnkey box build goes further by integrating the PCB into its enclosure with wiring, interfaces, and testing—delivering a complete, ready-to-use system. Box build is ideal when you need a full product, not just the circuit board.

3. What is an OEM box build and who needs it?

An OEM box build is a fully assembled and tested product manufactured according to an original equipment manufacturer’s (OEM’s) design and specifications. It’s essential for companies that want to outsource complex integration, without compromising on IP, compliance, or performance. OEMs in sectors like medical devices, automation, and energy rely on custom box builds to scale without building internal production lines.

4. What is the difference between turnkey and design-build in electronics?

In electronics, turnkey means the manufacturer takes your finalized design and delivers a complete product. In contrast, design-build combines design and manufacturing under one service—ideal if your concept isn’t fully engineered yet. For example, turnkey box build services are faster for market-ready products, while design-build is more flexible for early-stage development requiring engineering collaboration.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🟢 Conclusion:

From initial design to final delivery, box build assembly streamlines production, lowers costs, and ensures quality across every stage. Ready to simplify your supply chain and get your product to market faster? Contact UnitCircuits today for a tailored quote or engineering consultation.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!