Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Many OEMs struggle with the complexity of building custom control systems. Sourcing parts, ensuring compliance, and assembling enclosures delay time-to-market. This is where China’s box build services step in—offering turnkey solutions, high-quality integration, and affordability for industrial applications.

Box build services in China for industrial control systems provide turnkey assembly solutions, including PCB assembly, wiring, enclosures, integration, and testing. These services are ideal for OEMs needing complete, ready-to-install control units. With skilled labor, reliable sourcing, and global certifications like RoHS, Chinese manufacturers deliver high-quality, cost-efficient builds tailored to industrial automation and control requirements.

Let’s explore the technical details, real-world challenges, and how Chinese manufacturers solve pain points in industrial box build manufacturing.

What is a box build assembly and how is it used in industrial control systems?

A box build (also called systems integration or final assembly) refers to the entire process of assembling a finished product beyond the printed circuit board. For industrial control systems, this includes:

PCB assembly

Cable and wire harness integration

Enclosure or cabinet assembly

Mechanical installation (fans, power supplies, relays, etc.)

Software installation (if applicable)

Final inspection and functional testing

These assemblies are used in automation systems, robotics, HVAC control, power management, and intelligent equipment — wherever rugged, reliable, and compact electronic control is needed.

Industrial clients often demand high precision, compliance (e.g., RoHS, lead-free soldering), and endurance under harsh conditions. A strong box build provider addresses all of these.Industrial control systems (ICS), as defined by NIST, demand rugged, reliable components and integration for mission-critical performance.For a more technical explanation of what a box build includes, this Digi-Key guide is a valuable resource.

Why choose box build services from China for industrial electronics?

China’s box build service providers are uniquely positioned to deliver high-performance systems for industrial use. Here’s why:

-

Cost efficiency: Local component sourcing, large-scale manufacturing, and optimized labor reduce your production cost without sacrificing quality.

-

Full box build solution: One-stop services from PCB assembly to full product integration minimize vendor coordination.

-

Customization capability: Whether it’s a control panel, gas detection enclosure, or IoT module, custom control unit assembly is widely available.

-

Global compliance: Many Chinese providers are certified for ISO 9001, RoHS, and UL, supporting global exports.

UnitCircuits, for example, specializes in box build with PCB assembly and testing in China, delivering full turnkey builds from prototypes to volume production.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

What challenges exist in industrial box build manufacturing?

Industrial electronics integration is rarely straightforward. Common pain points include:

Component sourcing: Industrial-grade parts have stricter specs. Obsolescence and supply chain fluctuations increase sourcing difficulty.

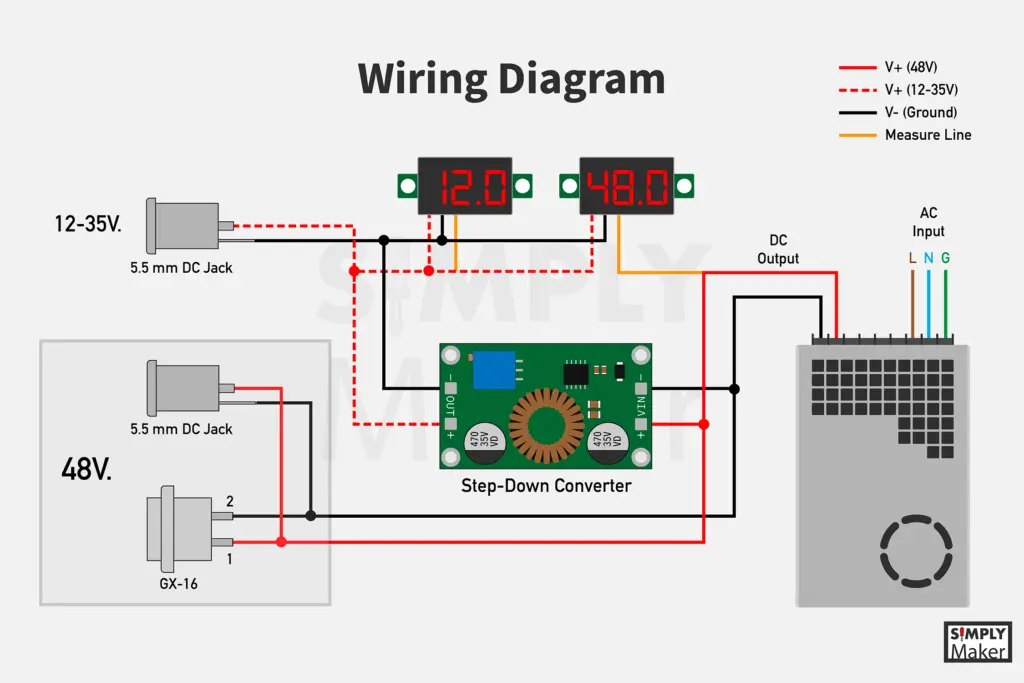

Wiring complexity: Multi-board systems with heavy wiring require skilled layout and labeling.

Mechanical integration: Incompatible enclosure sizes or poor thermal design can cause system failure.

Quality control: Inconsistent test processes lead to field failures and reputation damage.

A key differentiator in a top custom box build assembly China provider is their ability to solve these challenges proactively, not just reactively.

How does turnkey box build service simplify control system manufacturing?

Turnkey box build China services combine all aspects of production under one roof, offering:

Unified quality control

Tighter lead time management

Simplified supply chain coordination

Lower communication overhead

For example, instead of working with a separate PCB fab, wiring shop, and enclosure supplier, one partner handles everything — improving speed, accountability, and consistency.

Turnkey manufacturing is particularly effective for low MOQ box build manufacturing in China, ideal for pilot runs or niche industrial applications. Learn more about how turnkey PCB assembly can reduce coordination hassles, shorten timelines, and save costs.

What are the benefits of custom box build assemblies for automation systems?

Industrial automation often demands non-standard enclosures, unique cable routes, or application-specific layouts. Custom enclosure assembly for control systems allows OEMs to:

Optimize internal airflow and EMI shielding

Fit builds into unique panel spaces

Include specific connectors or user interfaces

Pre-wire for plug-and-play installation

Whether it’s a box build and final assembly for gas detection systems or automation panels, customization improves both function and field serviceability.

How do Chinese manufacturers ensure quality in box build and final testing?

Top-tier Chinese manufacturers implement multi-step test procedures:

AOI (Automated Optical Inspection) for PCBAs

Continuity and HiPot testing for cable assemblies

Functionality testing for entire systems

Burn-in tests for temperature and stress tolerance

Detailed inspection records for traceability

Providers like UnitCircuits offer a testing and quality inspection workflow that matches international OEM expectations. You can even request RoHS-compliant PCB assembly from China that passes EU audit standards. Read our testing methods guide to understand how high-quality testing impacts the reliability of control system assemblies. Top Chinese EMS providers often comply with IPC manufacturing standards, ensuring traceability, testing, and workmanship meet global benchmarks.

Is low MOQ box build manufacturing in China feasible for startups and OEMs?

Yes — this is a growing trend. Chinese factories now offer:

Low-volume and prototype support

Fast delivery box build assembly for industrial control (often 7–15 days)

Modular manufacturing lines for quick configuration

One-stop box build service for OEM electronics

This flexibility supports startups, IoT developers, and small-batch automation projects that need reliable output without committing to 10,000-unit runs.

How do box build services integrate cable and wiring assembly efficiently?

Cable and wiring integration is a critical success factor in any industrial control unit. Effective suppliers:

Use labeled wire harnesses

Build from detailed electrical schematics

Employ laser stripping or automatic cutting tools

Provide documentation and traceability per build

Some clients even request pre-loaded software, serial number labeling, and barcoded parts. Efficient wiring = faster field install and lower system failure.

Can I get lead-free or RoHS-compliant PCB assembly with box build services in China?

Absolutely. Many industrial clients today demand sustainability and legal compliance. Chinese manufacturers support:

Lead-free soldering service with component sourcing

Full RoHS material traceability

Certifications to prove compliance with EU directives

UnitCircuits, for example, emphasizes itself as a sustainable electronics manufacturing partner, helping OEMs meet EU RoHS requirements with our lead-free PCB process.

What industries benefit most from electronics box build with component sourcing in China?

Industries currently leveraging box build services from China include:

Factory automation & robotics

HVAC control systems

Environmental & gas detection systems

Smart grid / power management

Medical device enclosures

Agritech control units

Intelligent machine systems

Each requires rugged, tested, and reliable final product assembly, often in short lead times. That’s where full-service providers with strong sourcing networks shine.

What should you look for in a reliable box build manufacturer for control panels?

When sourcing a reliable box build manufacturer for control panels, consider these factors:

Can they handle both PCB assembly and enclosure integration?

Do they support low-volume runs or only high-volume?

Are they RoHS-certified and ISO-compliant?

Do they offer detailed inspection and testing?

Is there transparency in material sourcing and lead times?

Ask for samples, process walkthroughs, and visit the site if possible. A strong box build partner becomes a long-term strategic asset. Explore these 6 key purchase considerations to avoid costly mistakes when sourcing from China.

How does UnitCircuits deliver affordable and fast delivery box build assembly for industrial control?

At UnitCircuits, we specialize in affordable box build for intelligent machine systems and industrial control. Here’s what sets us apart:

Component sourcing in Shenzhen, close to global supply chains

In-house PCB assembly, control cabinet assembly, and custom enclosure builds

Fast prototyping with low MOQs

Global standards compliance, including RoHS and UL

Dedicated engineering support for early-stage design input

Ready to simplify your manufacturing with a full box build solution? We’re here to help.

FAQs

1. What does box build mean in electronics manufacturing?

In electronics manufacturing, box build refers to the process of assembling a complete end-use electronic product, including PCB assembly, wiring, mechanical installation, and enclosures. It goes beyond PCBA, integrating all components into a functional control system, ready for deployment in industrial or commercial environments.

2. What is the difference between box build and PCBA?

PCBA (Printed Circuit Board Assembly) involves assembling components onto a bare PCB. In contrast, box build assembly includes PCBA plus enclosure assembly, wiring, testing, and final product integration. It’s a turnkey solution ideal for OEMs needing complete, ready-to-use electronic systems.

3. What is an example of a box build assembly?

A typical box build assembly example is an industrial automation controller with a PCB, wiring harnesses, control buttons, connectors, and housed in a custom metal enclosure. It’s fully tested and ready for plug-and-play installation in smart factories, HVAC systems, or robotics.

4. What is a box build job description in a manufacturing setup?

A box build technician’s job description includes assembling PCBs into enclosures, routing and labeling cables, attaching connectors, performing functional tests, and ensuring the final unit meets industrial quality standards. This role is crucial in producing custom electronics for control systems.

Let me know if you'd like to localize these into other languages or integrate them into your blog page layout.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🟢 Conclusion:

Looking for a reliable partner in China for turnkey box build manufacturing? Let us help simplify your control system integration with fast, cost-effective, and compliant solutions. Contact UnitCircuits for a consultation today.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!