Quick Leads-PCBA

Why Capacitor Polarity Matters in PCB Assembly

Ever had a PCB fail unexpectedly? Maybe it worked fine during testing but shorted out after a few weeks? One of the most common yet avoidable issues in PCB assembly is incorrect capacitor polarity.

I’ve seen it happen too many times—a reversed electrolytic capacitor, a tiny mistake that leads to voltage spikes, circuit damage, or even an explosion. And the worst part? Fixing it after production is costly and time-consuming.

This guide will help engineers, PCB manufacturers, and sourcing managers avoid these problems by understanding:

- ✅ How to identify capacitor polarity (so you never install them backward)

- ✅ Best practices for capacitor orientation in PCB layout

- ✅ Sourcing high-quality capacitors (and avoiding supplier issues)

- ✅ How capacitor polarity affects PCB performance

What is Capacitor Polarity in PCB Assembly?

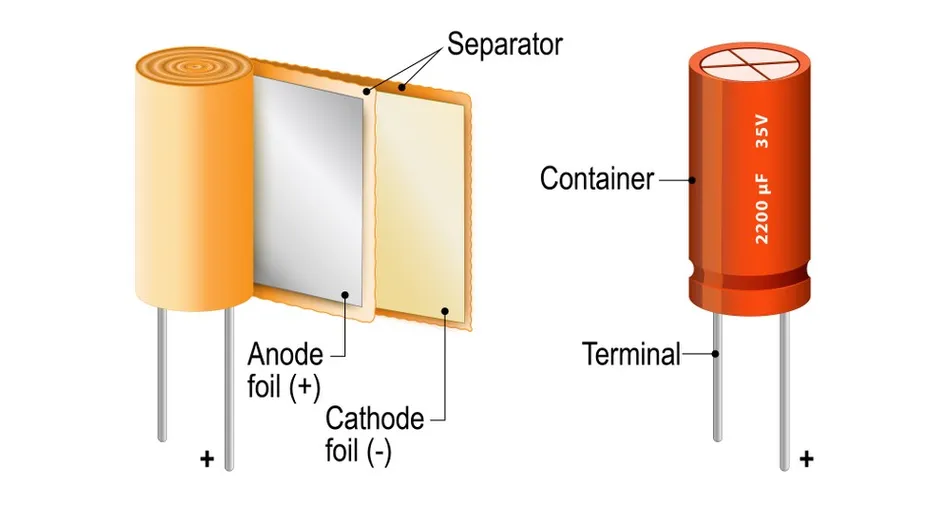

👉 Capacitor polarity refers to the correct orientation of a capacitor’s positive (+) and negative (-) terminals. Unlike non-polarized capacitors, which can be placed in any direction, polarized capacitors must be installed correctly, or they won’t function properly.

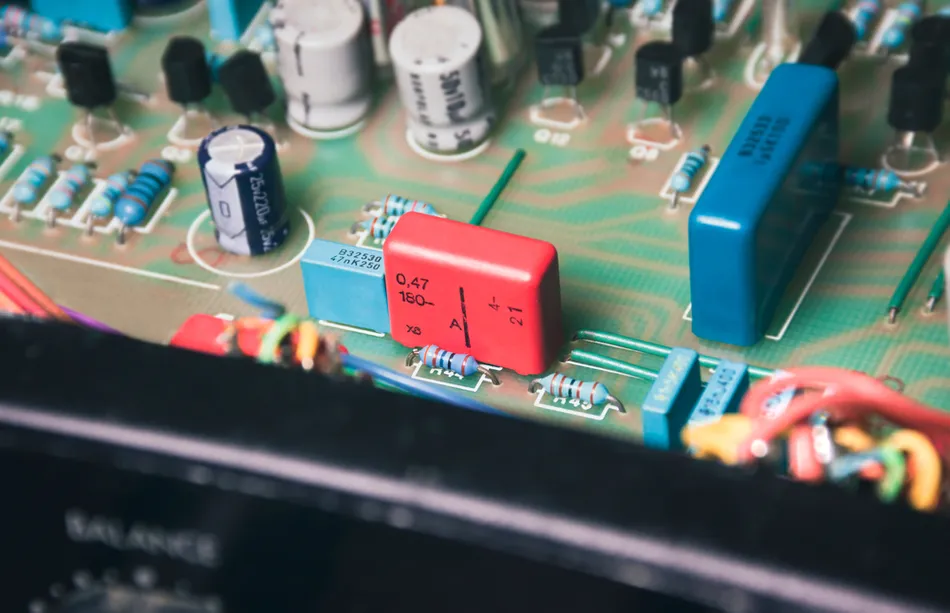

Common types of polarized capacitors include:

- Electrolytic capacitors (used in power supplies and filtering circuits)

- Tantalum capacitors (high-performance but highly sensitive to reverse voltage)

If placed incorrectly, a polarized capacitor can overheat, leak, or explode, damaging both the PCB and other components.

How to Identify Capacitor Polarity in circuit boards?

It’s surprisingly easy to mix up capacitor polarity markings, especially when dealing with different brands. Here’s what to look for:

🛠 Electrolytic Capacitor Polarity Markings

- Longer lead = Positive (+)

- Striped side = Negative (-)

- Minus (-) sign printed on the body

🛠 Tantalum Capacitor Polarity Markings

- Plus (+) symbol on the positive terminal

- No stripe (unlike electrolytic capacitors)

🛠 Ceramic & Film Capacitors

- No polarity – can be installed in any direction

⚡ Quick Tip: Always cross-check capacitor datasheets if the markings are unclear!

To correctly identify capacitor polarity, check for lead length, stripe indicators, or printed polarity signs. For a detailed guide, refer to Keysight’s capacitor polarity identification guide.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Industry Pain Points: Common Capacitor Polarity Issues in PCB Assembly

Let’s be real—capacitor polarity mistakes happen all the time, especially in high-volume PCB assembly. The key is knowing where things go wrong and how to fix them before they cost you money.

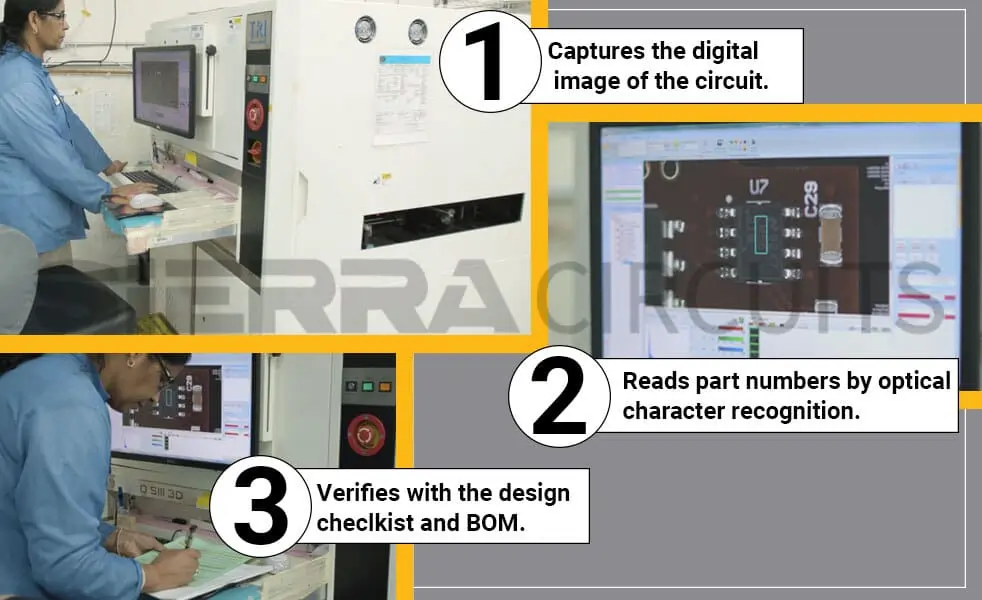

1️⃣ Wrong Capacitor Orientation in PCB Assembly

🔴 The Problem:

- Reversed electrolytic capacitors cause instant failure when powered.

- Assembly line errors (e.g., pick-and-place machines misreading polarity).

🟢 Solution:

- Use AOI (Automated Optical Inspection) to detect polarity errors before soldering.

- Always verify capacitor orientation in PCB layout design software.

2️⃣ Sourcing Capacitors with Incorrect Polarity Markings

🔴 The Problem:

- Some suppliers don’t label polarity clearly.

- Counterfeit capacitors often have incorrect polarity markings.

🟢 Solution:

- Source from verified suppliers (avoid cheapest options with vague specs).

- Perform incoming quality control (IQC) to check capacitor markings before assembly.

3️⃣ Capacitor Placement Rules for PCB Design

🔴 The Problem:

- Engineers don’t always leave space for correct capacitor orientation.

- Too many capacitors packed tightly causes overheating.

🟢 Solution:

- Follow PCB capacitor placement best practices.

- Add polarity indicators in the PCB silkscreen layer.

Many PCB failures result from incorrect electrolytic capacitor polarity placement. Engineers should always verify design polarity standards to prevent misalignment. This guide on capacitor considerations explains why polarity matters in real-world applications.

Comparison: Electrolytic vs. Tantalum vs. Ceramic Capacitors

| Feature | Electrolytic Capacitors | Tantalum Capacitors | Ceramic Capacitors |

|---|---|---|---|

| Polarity | Yes (+ and – terminals) | Yes (+ and – terminals) | No (non-polarized) |

| Voltage Sensitivity | High (wrong polarity = explosion) | Very High (sensitive to overvoltage) | Low |

| ESR (Equivalent Series Resistance) | Medium | Low | Very Low |

| Applications | Power filtering, smoothing circuits | High-reliability circuits, space-constrained designs | Signal coupling, decoupling, high-frequency applications |

⚡ Which One to Choose? If you’re working with power circuits, electrolytic capacitors are great—but always double-check polarity before soldering!

How to Check Capacitor Polarity Before Soldering in circuit boards assembly

Here’s a quick pre-soldering checklist to avoid mistakes:

✅ Use a multimeter (for electrolytic capacitors, the negative lead usually has lower resistance).

✅ Verify PCB silkscreen polarity labels match the capacitor’s actual markings.

✅ If unsure, check the datasheet—better safe than reworking a board later!

Common Capacitor Polarity Mistakes in PCB Assembly & How to Fix Them

🚨 What Happens If You Put a Polarized Capacitor Backwards?

- Reverse polarity = dielectric breakdown = failure

- Can overheat and explode (especially in high-voltage circuits)

✅ Prevention Tip: Use X-ray inspection for quality control after soldering.

Incorrectly placed polarized capacitors can cause short circuits and voltage failures. To avoid common polarity mistakes, check out this PCB polarity orientation guide.

🚨 Mistakes Engineers Make in PCB Design

❌ Forgetting to leave space for correct capacitor orientation

❌ Assuming all capacitors are non-polarized (ceramic vs. electrolytic confusion)

❌ Placing capacitors too close to heat-sensitive components

✅ Solution: Use DFM (Design for Manufacturability) software to check layout errors before production.

Engineers can reduce assembly errors by implementing proper capacitor orientation techniques. Learn more about capacitor polarity in PCB assembly to avoid costly rework.

FAQs

1. What’s the best way to source capacitors with correct polarity?

Look for reputable capacitor suppliers that provide detailed datasheets and polarity markings. Avoid cheap, unverified suppliers, as they often ship capacitors with inconsistent labeling.

2. How does capacitor polarity affect PCB performance?

Incorrect polarity can increase ESR (Equivalent Series Resistance), reducing efficiency and causing voltage drops. Over time, this degrades circuit performance and shortens the lifespan of the PCB.

3. Can I use a non-polarized capacitor instead of a polarized one?

It depends! Non-polarized capacitors (like ceramics) work well for AC circuits, coupling, and decoupling. But polarized capacitors are essential for DC power supply filtering.

4. Why do some PCB designs fail capacitor polarity checks?

Some designs lack proper silkscreen polarity markings or footprint mismatches between PCB and actual capacitor dimensions. Always cross-check the schematic, PCB layout, and BOM before assembly.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Final Thoughts: Avoid Costly Capacitor Polarity Mistakes!

By following these best practices, engineers and sourcing managers can prevent capacitor polarity issues, ensure long-term PCB reliability, and avoid expensive production reworks.

💡 Key Takeaway: Always double-check capacitor markings, source from reliable suppliers, and use AOI for verification!

🚀 Need help with capacitor sourcing or PCB assembly? Work with trusted PCB manufacturers to ensure top-quality components and error-free assembly!

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!