Quick Leads-PCBA

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

A Smarter Way to Build Electronics—From Start to Finish

If you’ve ever managed PCB assembly, mechanical integration, functional testing, and shipping across multiple vendors, you know it can feel like herding cats.

We’ve been there. That’s exactly why we built a one-stop box build and fulfillment service—to simplify the chaos and help you go from PCB to finished product faster, with fewer headaches, and at a better cost.

What Is Box Build Assembly in Electronics Manufacturing?

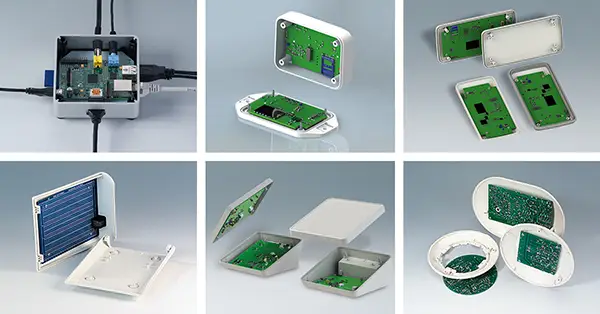

Box build assembly—also called systems integration or final product build—is the process of assembling a complete electronic product. It’s what happens after the PCB has been assembled and tested, when everything is integrated into the final enclosure, wired up, tested again, and packaged for delivery.

A typical box build process includes:

-

PCB integration (SMT or through-hole)

-

Wiring and harnessing

-

Enclosure mounting

-

Mechanical assembly

-

Functional and final testing

-

Quality control

-

Packaging and drop shipping

In a true one-stop EMS solution, you hand over your design files and receive the final product—fully tested, packaged, and ready to be shipped.

Need to meet environmental regulations? We offer RoHS-compliant PCB assembly from China, with lead-free soldering service and the certifications required to meet EU RoHS requirements.

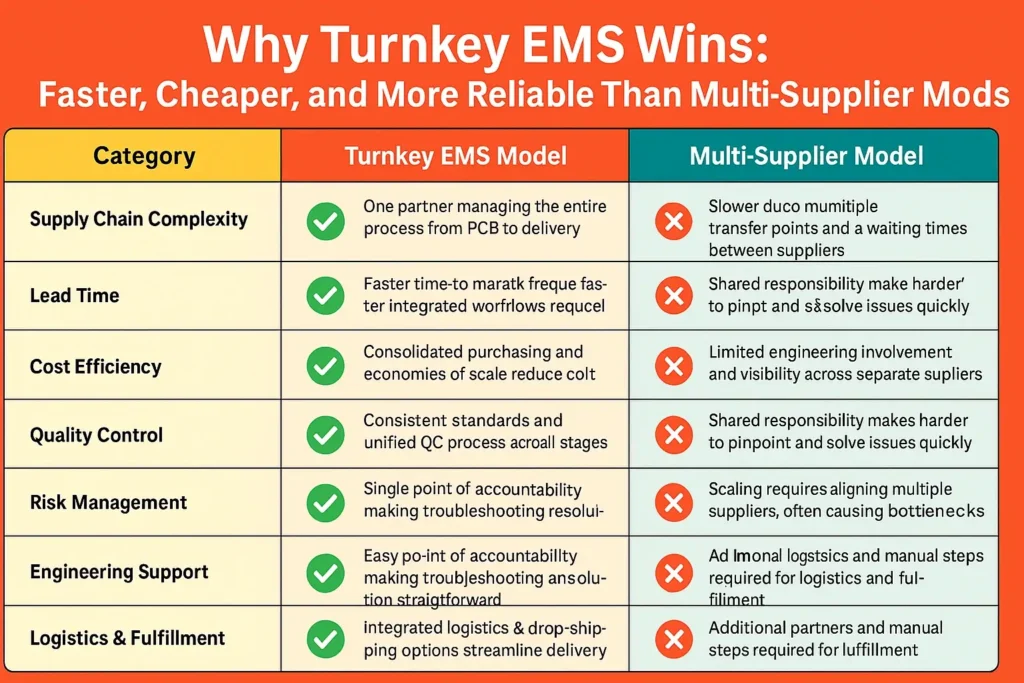

How Do Turnkey EMS Providers Streamline Product Development?

Let’s look at what happens when you work with multiple vendors versus working with a turnkey EMS provider like UnitCircuits.

📊 Comparison Chart: Multi-Vendor Model vs. Turnkey EMS

| Feature | Multi-Vendor Setup | Turnkey EMS Provider (UnitCircuits) |

|---|---|---|

| PCB Assembly | Outsourced separately | In-house SMT + THT |

| Component Sourcing | Handled by client | Fully managed BOM sourcing |

| Box Build | Handled by third-party | Completed internally |

| Functional Testing | Requires external lab | Integrated test stations |

| Packaging& Fulfillment | 3PL services needed | Direct shipping from factory |

| Lead Time | 6–10 weeks | 2–4 weeks average |

| Communication Overhead | High (multiple contacts) | One team handles it all |

| Cost Transparency | Hidden costs, scattered billing | All-inclusive, clear quotes |

We act as your contract manufacturing partner—from sourcing components and running assembly lines to testing and drop shipping.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

From PCB to Finished Product: What Does Full Integration Look Like?

Here’s what a full-service product journey looks like when you partner with us:

Step 1: Quotation & Feasibility Review

You send us your Gerber files and BOM. We review them for Design for Manufacturability (DFM), flag any issues, suggest alternatives, and return a transparent quote.

Step 2:

Component Procurement&PCB Assembly

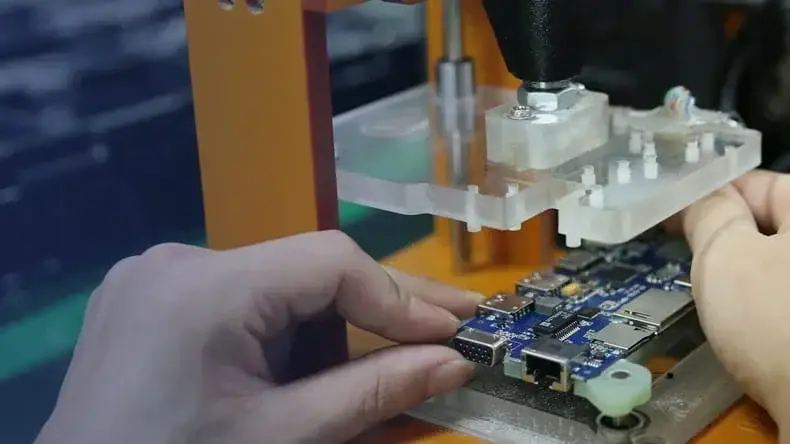

We source components through verified channels and proceed with SMT or through-hole assembly. We use lead-free soldering and verify quality with AOI/X-ray.

Step 3: Mechanical & Box Build Assembly

We mount the assembled PCB into your enclosure (plastic or metal), add wiring, displays, switches, connectors, and complete the full product build.

Step 4: Final Testing

We run functional tests based on your specifications. That includes FCT, ICT, burn-in, and more—performed in-house.

Step 5:

Packaging&Drop Shipping

We handle product labeling, ESD packaging, barcoding, and direct shipping to your warehouse or customers. We offer drop shipping for eCommerce models and support sustainable packaging.

This full-stack approach gives you control over timelines, cost, and quality—without juggling multiple suppliers.

What Are the Common Pain Points in PCB Assembly—and How to Fix Them?

We’ve worked with startups and enterprise teams alike. These are the recurring issues they face in traditional PCB production—and how we solve them:

❌ Problem 1: Too Many Suppliers

Before you even choose a supplier, it’s critical to evaluate your PCBA partner using the right criteria. We’ve outlined the 6 essential elements to consider when purchasing PCBA—from supplier credibility to material sourcing—that directly impact your box build project’s success.

Every step is handled by a different company. The result? Delays, confusion, and communication breakdown.

✅ Solution: Our one-stop EMS model keeps everything under one roof. You deal with one team. That’s it.

❌ Problem 2: Quality Inconsistency

When multiple vendors handle assembly, testing, and packaging separately, things fall through the cracks.

We follow rigorous testing protocols to ensure every unit meets your functional specs. If you’re curious about industry standards, we also break down the top 5 PCB testing methods used in EMS—including ICT, FCT, and AOI—in our detailed guide.

✅ Solution: We have in-process quality control checkpoints at every stage—assembly, box build, and final testing.

❌ Problem 3: Long Lead Times

Delays in sourcing, slow approvals, or rework can push projects back weeks or months.

✅ Solution: Our sourcing team identifies long-lead parts early and offers approved substitutes to keep your schedule on track.

❌ Problem 4: Non-Compliant Processes

If your product needs to comply with RoHS or other global standards, not every vendor is up to par.

✅ Solution: We follow a RoHS-compliant process, use certified materials, and provide all necessary documentation.

We’re not just a supplier—we’re your sustainable electronics manufacturing partner that builds for scale, speed, and compliance.

What Industries Benefit Most from Low-Volume PCB Assembly and IoT Product Services?

Our model supports both startups and established brands, especially those with smaller production runs or pilot projects.

We specialize in low volume PCB assembly + drop shipping services—perfect for industries where speed and agility are more important than sheer volume.

📊 Chart: Common Industries Using Our IoT and Low-Volume Services

| Industry | Sample Products | Special Requirements |

|---|---|---|

| IoT & Smart Devices | Gateways, sensors, wearables | Wireless modules, BLE/Wi-Fi, low MOQ |

| Medical Devices | Monitors, handheld diagnostics | Traceability, compliance (FDA/ISO) |

| Industrial Controls | PLCs, HMI modules, automation boards | Rugged enclosures, EMC compliance |

| Drones & Robotics | Motor controllers, nav systems | Lightweight build, power management |

| Consumer Electronics | Smart audio, accessories, game pads | Stylish packaging, fast-to-market |

With our IoT product assembly services, we also help configure firmware, run calibration, and provision smart devices before shipment.

Why Should You Trust a Contract Manufacturer for Your Next Electronics Build?

Here’s the real question: should you build in-house or go with a pro?

Let’s compare:

📊 Chart: In-House Build vs. EMS Provider (UnitCircuits)

| Category | In-House Manufacturing | EMS Provider (UnitCircuits) |

|---|---|---|

| Upfront Cost | High (machines, staff, tools) | Low—pay per project |

| Time to Market | Slower (setup + procurement) | Faster (everything pre-integrated) |

| Quality Management | DIY inspections | Certified, multi-step QC |

| Scalability | Limited | From 1 unit to 10,000+ |

| Certifications | You handle them | We’re ISO 9001, CE, RoHS compliant |

| Logistics&Shipping | External 3PL needed | In-house drop shipping & fulfillment |

We help you scale without the overhead—and bring technical expertise you won’t have to build from scratch.

Final Thoughts: From PCB to Finished Product, the Smart Way

When you’re juggling suppliers, timelines slip. Quality suffers. Costs spiral. I’ve seen it happen again and again.

That’s why working with a turnkey EMS provider is a strategic decision—not just a convenience.

We help you:

Ship products faster

Control quality from end to end

Cut total costs

Focus on your business, not supply chains

If you’re looking for a box build services partner who gets it, and who’s done it for medical, IoT, industrial, and consumer tech—we’d love to talk.

If you’re still weighing the benefits of working with a single supplier, our breakdown of why turnkey PCB assembly is a game-changer can give you clarity. From reduced risk to accelerated launch times, it’s about more than convenience—it’s a smarter growth strategy.

FAQs

1. What is the typical box build assembly process in turnkey EMS?

Yes. We specialize in low-volume PCB assembly and support small-batch orders without large upfront costs. Whether you're a startup testing a new IoT product or scaling gradually, our flexible production model ensures full support—from sourcing to shipping—without the burden of traditional manufacturing minimums.

2. How does box build differ from basic PCB assembly?

PCB assembly (PCBA) focuses only on placing components onto a circuit board. Box build services, on the other hand, involve integrating that assembled PCB into the final product—wiring, enclosing, testing, and fulfilling. It’s ideal for OEMs looking for a full product build, not just assembled boards.

3. Can you help assemble products from pre-built or sourced parts?

Yes. As a turnkey EMS provider, we can handle integration even if you supply partially assembled units or sub-components. Whether you need final product testing, enclosure installation, or custom packaging, we can complete the job and offer optional fulfillment services to ship directly to your end customer.

4. What’s included in the 5-step production flow for full electronics builds?

Our standard 5-step box build production includes: (1) BOM validation and sourcing, (2) PCB assembly, (3) mechanical integration, (4) functional testing, and (5) fulfillment and packaging. Each step is handled in-house to reduce lead times and improve traceability. We support both high-volume and low-volume PCB assembly + drop shipping.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

✅ Let’s simplify your electronics manufacturing process

Upload your BOM, Gerber, or 3D enclosure files — our engineers will review them and suggest optimizations, absolutely free.

📦 No MOQ 💡 Fast Turnaround 🧪 100% E-tested

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!