Quick Leads-PCBA

Smart machines and actuator controls are shrinking in size but growing in complexity. Traditional PCBs can’t keep up with the performance demands. That’s where HDI PCBs come in—compact, high-speed, and precise. Let’s dive into why HDI is no longer optional for intelligent automation systems.

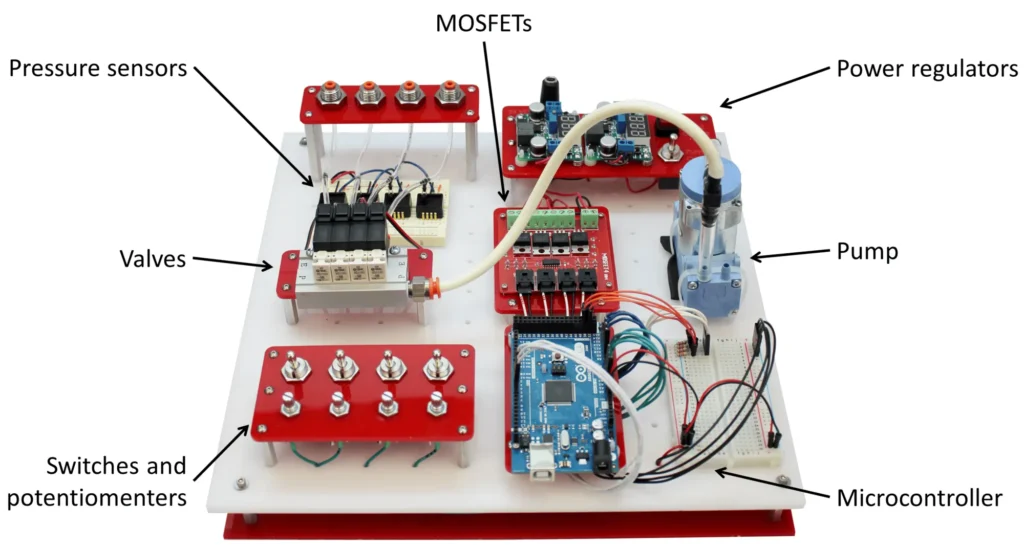

HDI PCBs (High Density Interconnect printed circuit boards) are critical in smart machines and actuator controls due to their compact design, superior signal integrity, and high-speed data handling. They support miniaturized layouts without compromising performance, enabling precise motion control and faster response times in robotics, industrial automation, and intelligent systems.

To understand why HDI PCBs are irreplaceable in modern smart control systems, we need to examine both the technical advantages and how they solve real-world challenges engineers face.

What is the Use of HDI PCB in Smart Automation Systems?

When I first started designing motion control boards for robotics, traditional PCBs hit their limit fast—both in signal reliability and form factor. HDI PCBs made the impossible… work.

These boards offer more routing space in less area. With features like microvias, laser-drilled holes, and thin lines/spaces, HDI PCBs for industrial automation systems offer:

-

Faster signal transmission with fewer losses

-

Denser component placement—ideal for compact smart actuator control boards

-

Better EMI performance in high-speed systems

Whether you’re building robotic arms or precision CNC controls, HDI PCB for smart machines just makes sense.

What Sets HDI PCBs Apart from Traditional PCBs?

Let’s compare the two side-by-side:

| Feature | Traditional PCB | HDI PCB |

|---|---|---|

| Via Type | Through-hole | Microvia, blind/buried vias |

| Signal Speed | Moderate | High-speed |

| Size | Larger | Compact |

| Cost | Lower upfront | Higher, but higher performance |

| EMI Performance | Basic shielding | Advanced routing + lower EMI |

| Application | General | Robotics, medical, defense, AI |

High density interconnect PCB technology wins hands down for advanced designs needing speed, signal integrity, and tight space handling. HDI boards enable high-density routing through microvias and buried vias, allowing more functions in less space. If you’re planning your next layout, these HDI PCB design guidelines from Altium are a great reference.

Why HDI PCB Is Essential for Actuator Control Precision

Precision actuators work on millisecond response times. A signal lag could throw off an entire production line. That’s why I always recommend HDI PCB for actuator control.

Why it matters:

-

Faster signal propagation reduces command-response delay

-

Reduced noise from better ground routing

-

Compact size allows placement near sensors/actuators, minimizing cable loss

And if you’re working with smart actuator control board HDI, it gets even better—these boards enable edge processing and feedback loop optimization, not just raw control. Minimizing interference and maintaining signal speed are key. These HDI signal integrity strategies explain how proper layout ensures actuator precision.

Industry Pain Points: Why Traditional PCB Assembly Fails Smart Machines

From my experience with clients in automation and robotics, here are the most common issues they face with regular PCBs:

-

Miniaturization Bottleneck – can’t place all needed components

-

Signal Interference – poor routing = noisy signals = bad actuator response

-

Layer Stack Complexity – 10+ layers drive up cost and reduce thermal stability

HDI PCBs solve these pain points. That’s why forward-looking engineers are switching to them for smart robotics and sensor-laden actuator systems.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

How HDI PCB Assembly Solves Real Engineering Problems

Let’s talk real solutions. HDI boards:

-

Use blind and buried vias to route signals in tight spaces

-

Allow higher pin-count packages (BGA, QFN) for smart chips

-

Reduce layer count but boost performance

-

Support build-up stackups for better thermal and mechanical strength

If you’ve ever had EMI issues with a motor driver or feedback jitter in a servo loop, HDI helps minimize those by shortening paths and shielding sensitive routes.

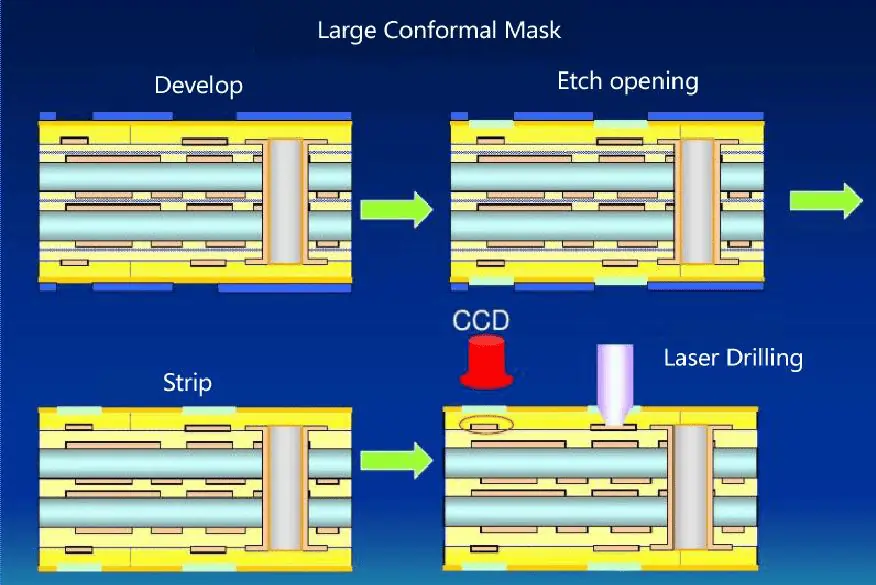

The Process of HDI PCB Manufacturing: What Engineers Need to Know

Here’s what happens when we build your HDI board:

We use high-end DFM tools and offer real-time stackup validation to avoid surprises.

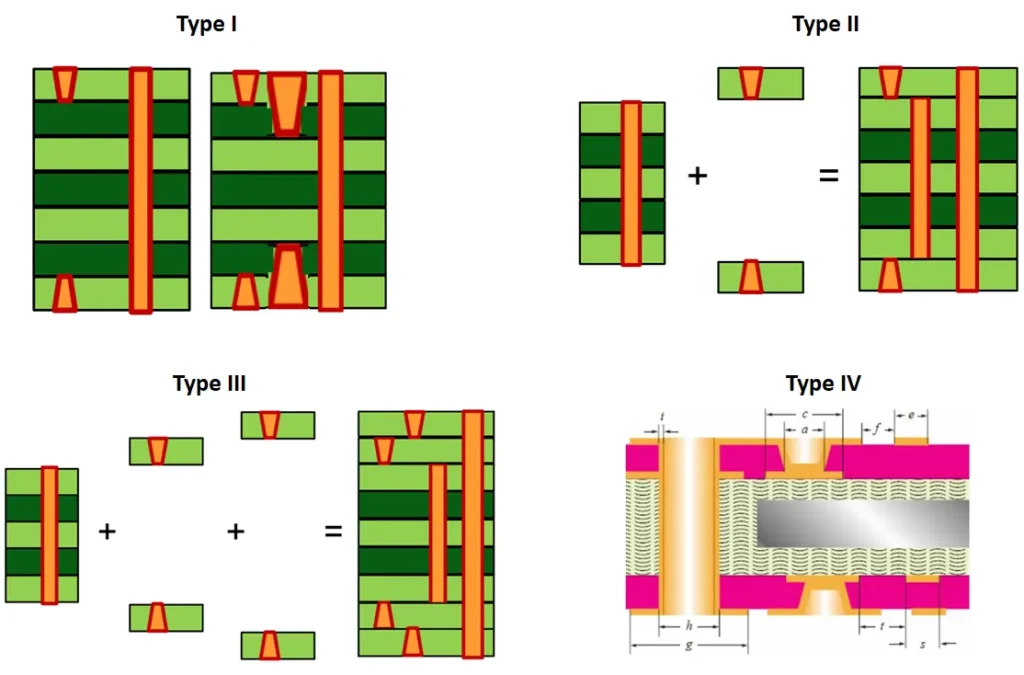

What Is the Structure of an HDI PCB?

HDI PCBs typically include:

-

Microvias: 0.1mm laser-drilled for high-density routing

-

Via-in-pad technology: space-saving for BGAs and chips

-

Build-up layers: improve routing without adding bulk

This gives your motion control board fewer layers, smaller footprint, and better electrical stability—all critical in industrial electronics PCB supplier applications.

Choosing the Right HDI PCB Supplier for Motion Control Projects

Not all suppliers understand the needs of automation. Here’s what to look for:

-

HDI PCB prototype no MOQ: For R&D and design validation

-

Quick turn options: When your client needs it yesterday

-

Functional Testing: Ensure zero-fault actuator board delivery

-

Experience: Robotics and industrial design-specific know-how

Why Engineers Choose Us: Real Advantages of Our HDI PCB Service

We’re not just fabricators. We’re your partners in product success.

-

DFM review on all files before production

-

Fast turnaround from prototype to mass production

-

Custom stackups for power and logic integration

-

Full functional testing to reduce field failure

Many of our customers come from robotics and actuator control industries, where HDI PCB with full functional testing is a non-negotiable.

FAQs

1. Is it possible to order HDI PCB prototypes with no MOQ for testing purposes?

Absolutely. We offer HDI PCB prototype with no MOQ, ideal for early-stage testing or pilot runs. Engineers often need to validate designs without committing to large volumes. Our low-barrier prototyping service lets you fine-tune your smart actuator control board HDI designs efficiently—before ramping up to full production.

2. How can HDI PCBs improve reliability in motion control systems?

Precision motion control requires consistency. HDI PCBs for actuator control use blind and buried vias to shorten signal paths, which reduces EMI and latency. This architecture boosts reliability, especially in industrial automation systems, where timing accuracy and durability are non-negotiable.

3. Can you get fast turnaround times for low volume HDI PCB manufacturing in China?

Yes, and that’s one of our strengths. Our team specializes in low volume HDI PCB manufacturing in China with fast turnaround—from 2 to 7 days depending on specs. This is perfect for automation startups or R&D teams needing rapid iteration without sacrificing quality or budget.

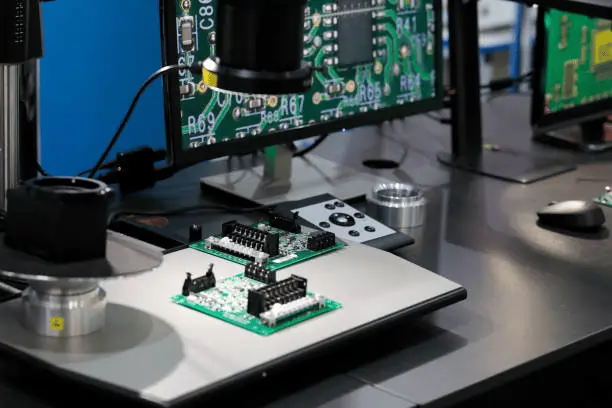

4. What type of testing is recommended for HDI PCBs in robotics systems?

For robotics, we recommend full functional testing on all custom HDI PCB for robotics systems. Beyond standard electrical tests, this includes checking actuator signal feedback, load responses, and thermal stability. Functional testing ensures your board performs flawlessly in real-world operating conditions, not just on paper.

For actuator boards, functional testing is a must—but it's only one part of the quality equation. Learn about the top 5 testing methods in PCB assembly to make sure your HDI boards pass real-world use cases.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion: Don’t Let Your PCB Limit Your Innovation

HDI PCBs are reshaping smart machine design—from better space use to faster signal flow. Whether you’re building robotics or high-precision actuator systems, HDI is the foundation. Have questions or a project? Let’s talk—our team specializes in HDI solutions that just work.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!