Quick Leads-PCBA

Introduction: Why Reading Circuit Diagrams Correctly Matters

Ever designed a PCB that looked perfect on-screen but turned into a manufacturing nightmare? You’re not alone. Many engineers can read circuit diagrams, but reading them with manufacturability in mind is a whole different skill.

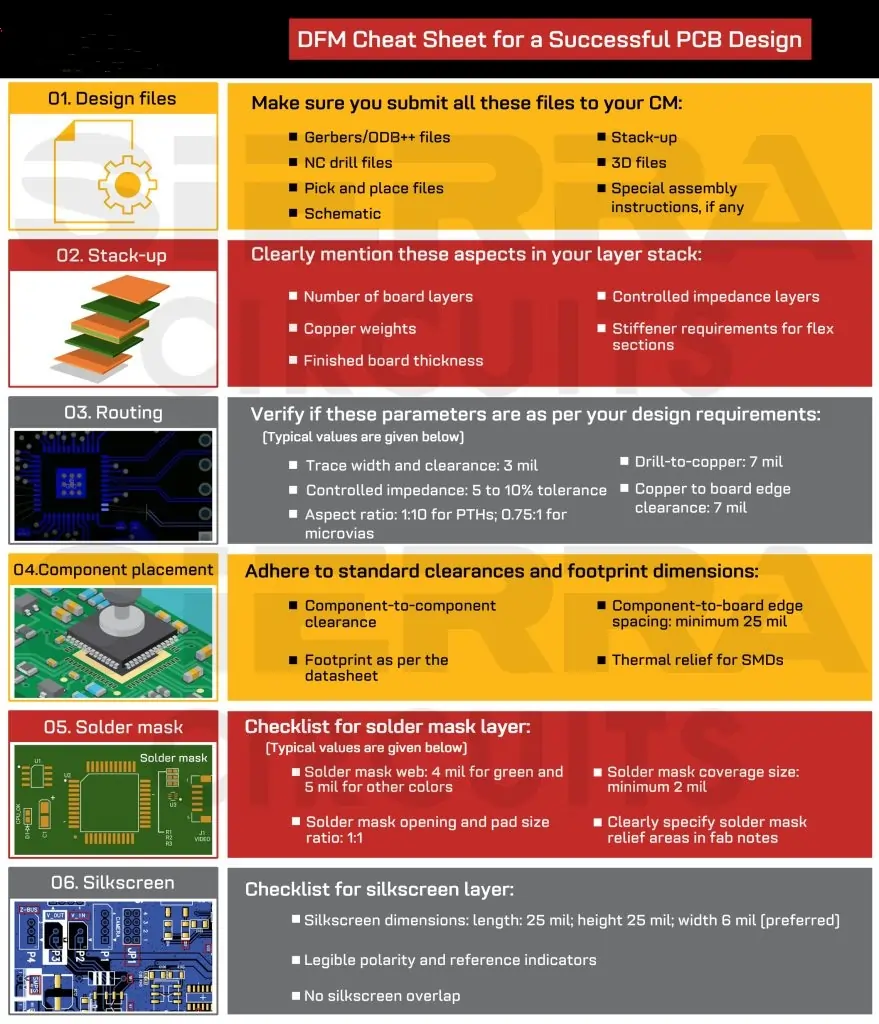

Ignoring DFM (Design for Manufacturability) principles can lead to higher costs, production delays, or even complete board failure. The good news? A few key strategies can help you design PCBs that are both functional and easy to manufacture.

In this guide, I’ll walk you through:

✔️ How to read circuit diagrams with PCB manufacturability in mind

✔️ The most common mistakes engineers make (and how to avoid them)

✔️ DFM best practices to ensure smooth PCB fabrication and assembly

By the end, you’ll know exactly how to optimize your circuit diagrams for real-world PCB production. Let’s dive in!

How to Read Circuit Diagrams for PCB Manufacturability

“To read circuit diagrams for better PCB manufacturability, start by understanding schematic symbols, trace connections, and applying DFM guidelines. Optimize trace width, component placement, and spacing to prevent manufacturing defects. Ensure clear labeling, minimize vias, and follow industry standards for efficient PCB assembly.”

That’s the short answer. Now, let’s break it down step by step.

1. Understanding Circuit Diagrams in PCB Design

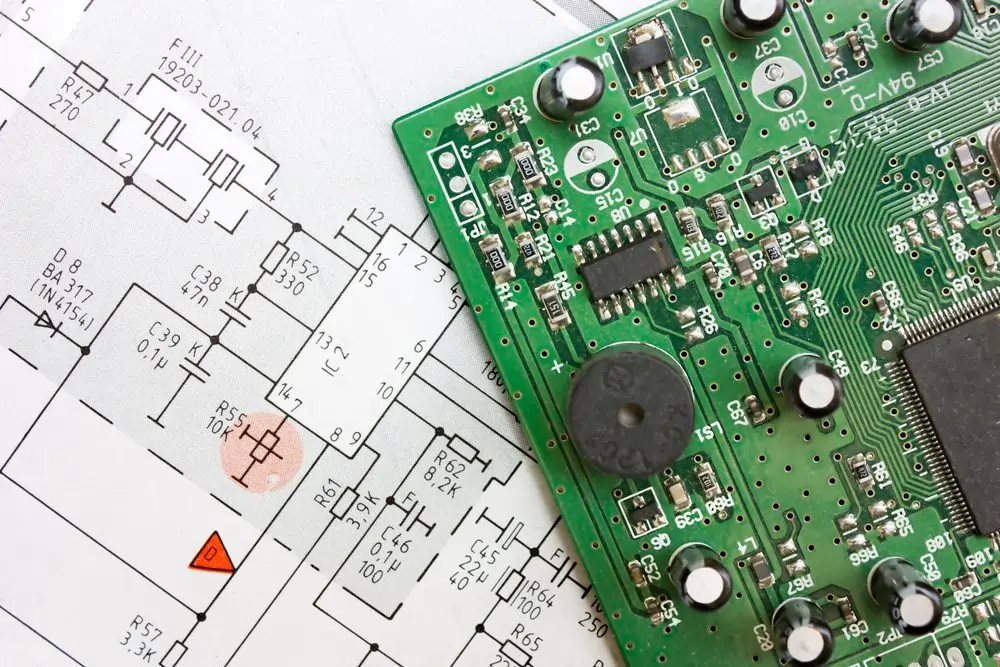

A circuit diagram (schematic) is the foundation of every PCB design. But just understanding what a circuit does isn’t enough—you need to interpret it for manufacturing.

🔹 Key Elements of a Circuit Diagram

1️⃣ Reference Designators – Labels like R1, C2, U3 help identify components. These should match your BOM (Bill of Materials).

2️⃣ Nets & Connections – Lines that show how components are connected. Thicker nets mean power traces, thinner ones carry signals.

3️⃣ Ground & Power Symbols – Essential for understanding current flow and avoiding grounding issues.

4️⃣ Component Symbols – Resistors, capacitors, diodes, transistors—each has a unique symbol, which you must read correctly.

✅ Pro Tip: When reading a schematic, always follow the signal flow from power input to ground, like reading left to right in a book.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

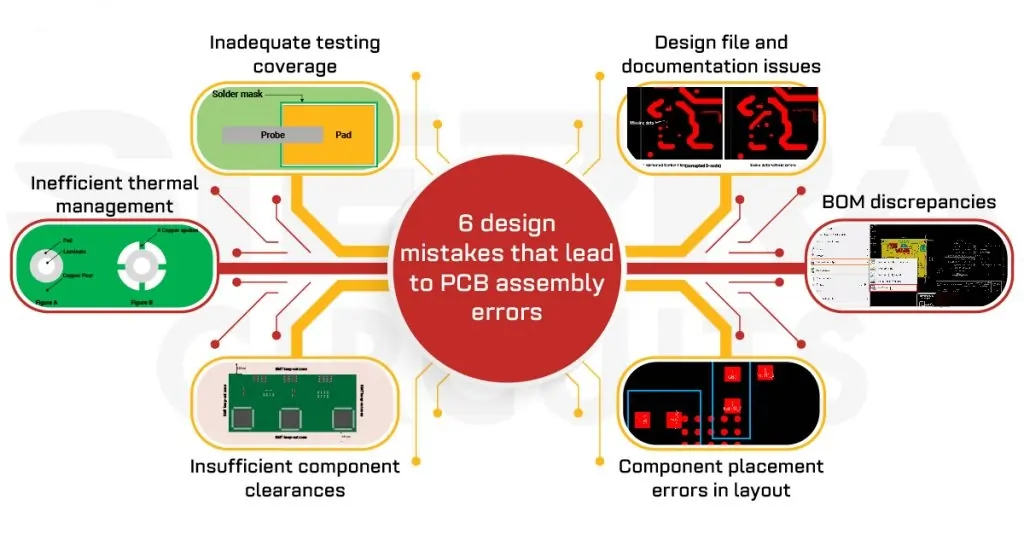

2. The Industry’s Biggest Pain Points in PCB Manufacturability

Many circuit designs that work in theory fail in manufacturing because they ignore key PCB production constraints.

Here are the top manufacturing challenges engineers face—and how to fix them.

🔹 Common Mistakes in PCB Circuit Diagrams

❌ 1. Overlapping Traces & Poor Spacing

- Problem: Too-tight routing leads to short circuits during etching.

- Solution: Follow IPC-2221 clearance rules—keep traces at least 0.007” to 0.010” apart.

❌ 2. Ignoring Thermal Management

- Problem: Heat buildup causes board failure or requires costly rework.

- Solution: Use thermal reliefs, wider traces for power lines, and add heat sinks where needed.

❌ 3. Unoptimized Via Placement

- Problem: Too many vias increase cost and can lead to signal integrity issues.

- Solution: Minimize via count and use larger vias for power lines.

❌ 4. Poor Component Placement

- Problem: Components placed too close together make assembly harder.

- Solution: Leave sufficient spacing for pick-and-place machines to avoid misalignment.

3. DFM Guidelines for PCB Layout: Best Practices

Design for Manufacturability (DFM) ensures your PCB can be produced quickly, reliably, and affordably. Here’s how:

🔹 How to Improve PCB Manufacturability in Design

✅ Use Standard Trace Widths

- For power traces, use ≥10 mils.

- For signal traces, use 5-6 mils.

- Don’t go below 3 mils unless necessary.

✅ Minimize Via Complexity

- Avoid blind/buried vias unless required (they increase cost).

- Use larger via sizes for power and ground nets.

✅ Standardize Component Footprints

- Stick to common package sizes (e.g., 0603, 0805, 1206 for resistors/capacitors).

- Check component availability before finalizing the design.

✅ Plan for Solderability

- Ensure adequate pad sizes for easy soldering.

- Use thermal relief pads to prevent solder bridges.

✅ Keep Signal Integrity in Mind

- Use shorter traces for high-frequency signals.

- Separate analog and digital sections to avoid noise issues.

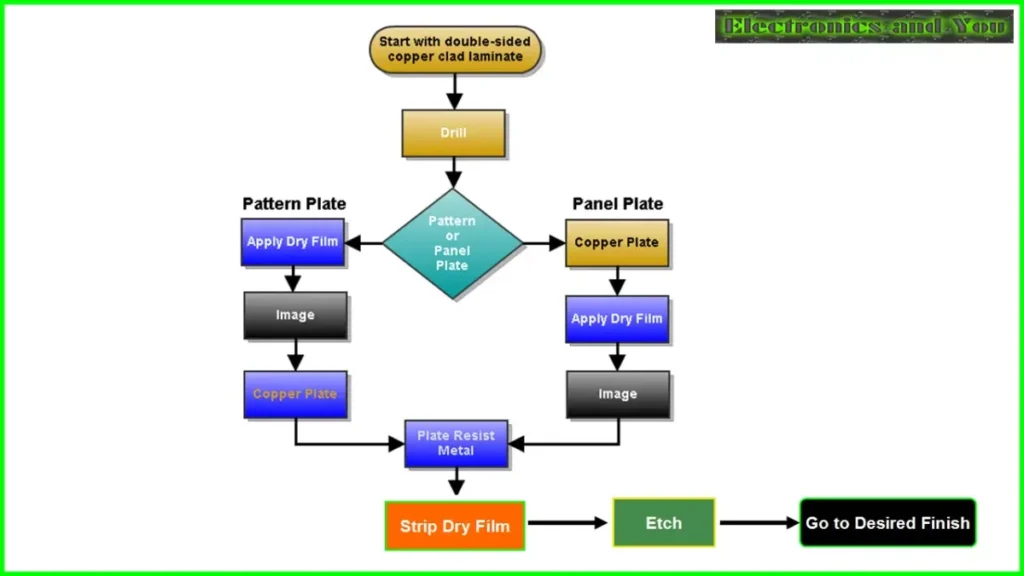

4. Step-by-Step Guide to Ensuring PCB Manufacturability

Step 1️⃣: Optimize Your Schematic for PCB Layout

- Label every net clearly.

- Avoid crossing signal lines unnecessarily.

Step 2️⃣: Choose the Right PCB Materials

- FR4 is the standard, but use high-Tg materials for high-temp applications.

- For RF boards, consider Rogers laminates.

Step 3️⃣: Follow PCB Assembly Design Rules

- Check minimum clearance rules for your manufacturer.

- Ensure your drill hole sizes match the fab specs.

Step 4️⃣: Run a DFM Check Before Production

- Use DFM tools in Altium, KiCad, or Eagle to catch manufacturability issues.

- Get a prototype made before mass production.

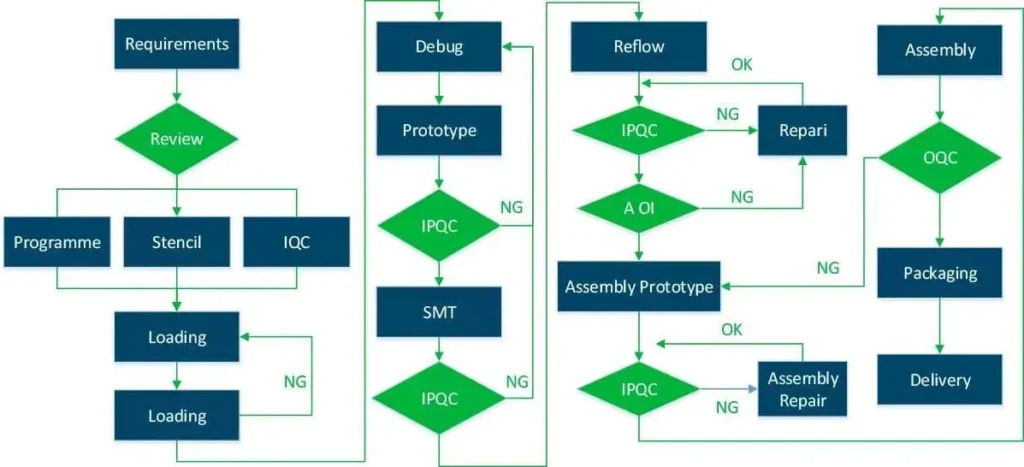

5. Turnkey PCB Assembly Design Tips for Faster Production

If you’re using a turnkey PCB assembly service, here’s how to speed up production:

🚀 Keep Your BOM Clean – Double-check that part numbers match the footprints in your design.

🚀 Use Fiducial Marks – These help automated pick-and-place machines align components correctly.

🚀 Minimize Hand Soldering Requirements – Design your board for 100% machine assembly whenever possible.

🚀 Standardize Connectors & Mounting Holes – Avoid custom footprints unless necessary.

🚀 Communicate With Your Manufacturer – If in doubt, ask your PCB fab for their recommended DFM guidelines.

FAQs

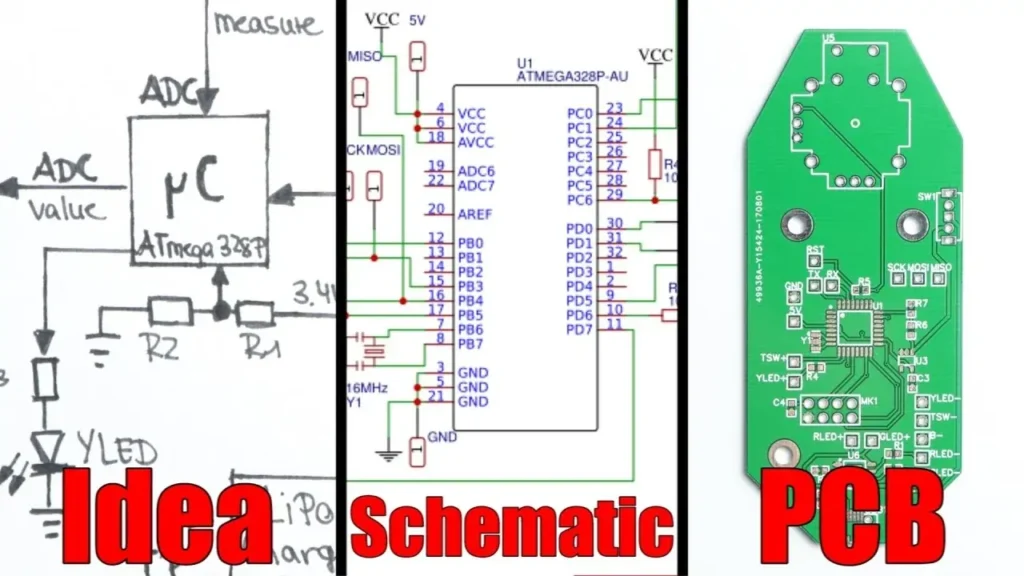

1. What are the top 3 important steps in PCB design and layout?

The three most critical steps in PCB design for manufacturing (DFM) are:

1️⃣ Schematic Design – Create a well-labeled circuit diagram that accurately represents the electrical connections.

2️⃣ PCB Layout Optimization – Convert the schematic into a PCB layout, ensuring trace width, via placement, and component spacing meet manufacturability guidelines.

3️⃣ DFM Validation – Perform a design rule check (DRC) to catch errors and ensure PCB manufacturability before fabrication.

✅ Optimizing circuit diagrams for PCB fabrication early prevents costly rework.

2. What is the difference between a PCB layout and a circuit diagram?

A circuit diagram (schematic) is a symbolic representation of electrical connections, while a PCB layout is the physical design of the board.

- A schematic diagram shows how components are connected but doesn’t define trace routing.

- A PCB layout translates the schematic into a manufacturable design, specifying trace paths, copper layers, and component placements.

Understanding both is key to how to ensure a PCB design is easy to manufacture, reducing errors in turnkey PCB assembly.

3. What must be kept in mind while constructing a circuit diagram?

To create a DFM-friendly circuit diagram:

✔ Use clear labeling for nets, power, and ground connections.

✔ Minimize crossing signal lines to improve readability.

✔ Follow best practices for PCB manufacturability, ensuring proper trace spacing and component orientation.

✔ Consider DFM guidelines for PCB layout—a bad schematic leads to a difficult-to-manufacture PCB.

A well-structured schematic diagram ensures seamless transition to PCB fabrication and assembly, saving time and cost.

4. How to read a PCB for beginners?

Reading a PCB starts with identifying key elements:

🔹 Component Labels (Reference Designators) – Match parts to the circuit diagram.

🔹 Traces & Vias – Follow signal paths to understand connectivity.

🔹 Power & Ground Planes – Locate key power distribution areas.

For beginners, understanding circuit board diagram symbols is essential. Mastering how to read a circuit board diagram helps with troubleshooting, repairs, and improving PCB manufacturability during design.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

6. Final Thoughts: Why DFM Matters for Every Engineer

Reading circuit diagrams correctly is only half the battle—the real challenge is ensuring your design can be manufactured efficiently.

To recap, here’s what you should always do:

✅ Read schematics with DFM in mind

✅ Avoid overlapping traces, poor spacing, and excessive vias

✅ Follow standard PCB design rules

✅ Run a DFM check before manufacturing

If you want flawless PCB production, you need a manufacturer that understands both design and assembly. Our PCB Assembly Services ensure your designs are built right the first time.

📞 Need help optimizing your PCB design? Contact us today for a free DFM consultation!

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!