Mixed Technology PCB Assembly

High-Quality Mixed Technology PCB Assembly Services Since 2017

- Single & Double-Sided Mixed Technology Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports Through-Hole, SMT, BGA, Micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

Mixed Technology PCB Assembly

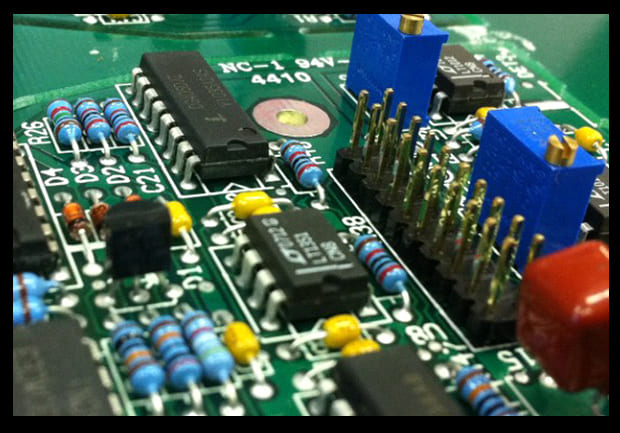

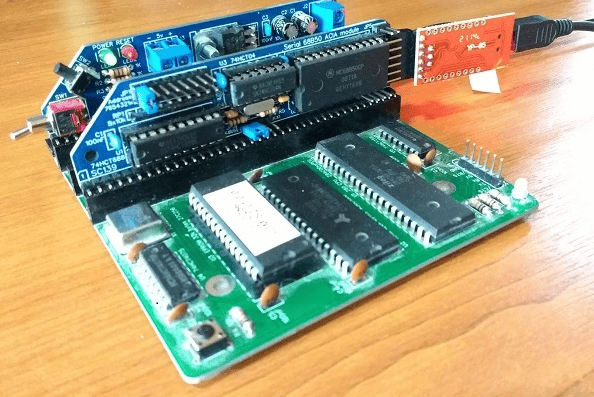

Mixed Technology PCB Assembly is the process of combining Surface Mount Technology (SMT) and Through-Hole Technology (THT) in a single hybrid PCB assembly. This hybrid approach leverages the strengths of both SMT and THT assembly, ensuring enhanced durability, compact designs, and high-performance electronic devices.

For engineers, designers, and businesses looking to optimize their PCB manufacturing process, understanding the advantages of Mixed Technology PCB Assembly is crucial. Whether you are new to PCB assembly or seeking a turnkey PCB assembly solution, this guide will cover key benefits, applications, and best practices.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is Mixed Technology PCB Assembly?

Mixed Technology PCB Assembly is a hybrid PCB manufacturing process that integrates Surface Mount Technology (SMT) and Through-Hole Technology (THT) to assemble components onto a single board. In this approach, SMT components are mounted directly onto the PCB surface, while THT components are inserted through drilled holes and soldered for enhanced mechanical strength.Learn more about the advantages of combining SMT and THT in PCB assembly in our in-depth guide: 👉SMT vs. THT: Why Combining Them in PCB Assembly Offers Speed, Reliability, and Performance.

By combining the compact size and automation efficiency of SMT assembly with the durability and reliability of THT assembly, this method is ideal for complex electronic applications, including industrial control systems, automotive electronics, and power management circuits.

Why is Mixed Technology Important?

The combination of SMT and THT assembly allows manufacturers to leverage the advantages of both technologies, optimizing PCB design flexibility and production efficiency. Mixed Technology PCB Assembly is particularly valuable for:

- High-density PCB designs, where SMT components maximize space utilization.

- Power electronics and connectors, which require the mechanical stability of THT components.

- Applications requiring durability, such as aerospace, telecommunications, and medical devices.

What is the Mixed Technology PCB Assembly Process?

The Mixed Technology PCB Assembly process integrates surface mount and through-hole technologies on a single board. The key steps include:

- SMT Component Placement – Small electronic components are precisely placed and soldered onto the PCB surface using automated pick-and-place machines.

- THT Component Insertion – Larger, high-power, or mechanically stressed components are inserted through pre-drilled holes in the PCB.

- Wave Soldering or Selective Soldering – THT components are secured using wave soldering or selective soldering to ensure strong electrical connections.

- Final Inspection & Testing – The assembled PCB undergoes AOI (Automated Optical Inspection) and functional testing to guarantee performance reliability.

👉 Related Topic: Looking for fast, reliable PCB assembly? Learn about our Turnkey PCB Assembly Services for a one-stop electronics manufacturing solution.

The Benefits of Mixed Technology PCB Assembly

Mixed Technology PCB Assembly provides several advantages by integrating Surface Mount Technology (SMT) and Through-Hole Technology (THT) in a single hybrid PCB assembly. This approach allows manufacturers to maximize efficiency, durability, and performance in electronic products.

1️⃣ Best of Both Worlds: SMT Efficiency & THT Reliability

By combining SMT and THT assembly, Mixed Technology PCB Manufacturing utilizes:

- The compact size and high-speed automation of SMT for space-saving PCB designs.

- The mechanical strength of THT components, ensuring durability in high-stress environments such as industrial automation, automotive, and aerospace applications.

2️⃣ Higher Component Density for Advanced PCB Designs

The integration of Surface Mount Technology (SMT) in Mixed Technology PCB Assembly enables high-density PCB designs, allowing for compact, lightweight, and high-performance circuits. This is particularly beneficial for:

- Smartphones and advanced consumer electronics, where space optimization is crucial.

- IoT devices and wearable technology, which require miniaturized components with high integration levels.

3️⃣ Greater Durability & Mechanical Strength

Through-Hole Technology (THT) components provide superior mechanical stability, making them ideal for products exposed to:

- Constant physical stress and vibrations, such as automotive electronics and industrial machinery.

- Harsh environmental conditions, including high-temperature applications like aerospace and power electronics.

By leveraging Mixed Component PCB Manufacturing, engineers can design rugged and reliable circuit boards without compromising size or efficiency.

4️⃣ Cost-Effective for Complex PCB Projects

Mixed Technology PCB Assembly provides a cost-efficient solution for complex PCB manufacturing, as it optimally balances:

- SMT’s high-speed, automated assembly, reducing labor costs.

- THT’s durability, ensuring long-term reliability in mission-critical applications.

- Hybrid PCB manufacturing, which allows for scalability and production flexibility based on component needs.

This makes Mixed Technology PCB Manufacturing ideal for:

✔ Industrial control systems

✔ Medical electronics

✔ Telecommunications hardware

Comparison of SMT/THT/Mixed Technology

| Assembly Type | Process | Best For | Main Advantage |

|---|---|---|---|

| SMT (Surface Mount) | Solder components onto PCB surface | Small, compact devices | Automated, high-speed assembly |

| THT (Through-Hole) | Insert components through PCB holes | High-power applications | Strong mechanical bonds |

| Mixed Technology | Combine SMT & THT | Complex, high-performance designs | Best of both worlds |

The Common Defects in Mixed Technology PCB Assembly

Even though Mixed Technology PCB Assembly combines the advantages of SMT and THT assembly, certain manufacturing challenges can arise. Understanding and addressing these issues ensures higher reliability and performance in hybrid PCB manufacturing.

1️⃣ Soldering Issues in Mixed Technology PCB Assembly

Defects such as cold solder joints, solder bridges, or insufficient solder may occur, especially during the transition between SMT and THT assembly processes. Common causes include:

- Incorrect solder paste application for SMT components.

- Uneven heating during reflow or wave soldering.

- Insufficient flux or poor wetting of THT component leads.

🔹 Prevention Tip: Ensuring proper temperature control and soldering process calibration helps eliminate these defects.

2️⃣ Component Misalignment & Placement Errors

Since SMT and THT components require different assembly techniques, there is a risk of:

- Misalignment of SMT components during high-speed pick-and-place operations.

- Incorrect hole sizes or misdrilled holes for THT components.

- Shifting during soldering, leading to electrical failures.

🔹 Prevention Tip: Proper machine calibration, precise component placement, and accurate PCB design reduce misalignment risks.

3️⃣ Inconsistent Soldering Between SMT and THT Components

Since SMT reflow soldering and THT wave/selective soldering require different techniques, potential issues include:

- Uneven solder flow, leading to weak joints.

- Variation in solder joint quality between SMT pads and THT leads.

- Excessive heat exposure causing damage to sensitive SMT components.

🔹 Prevention Tip: Implement independent soldering profiles for SMT and THT, ensuring uniform solder quality and joint strength.

Even though Mixed Technology PCB Assembly combines the benefits of both SMT and THT, it can still present some manufacturing challenges, including soldering defects, component misalignment, and inconsistent solder quality. Discover how to overcome these challenges and optimize your hybrid PCB assembly process in our guide:👉 Hybrid PCB Assembly: Overcoming Challenges When Combining SMT and THT.

What is the Mixed Technology Setup?

The Mixed Technology PCB setup involves:

- Placing SMT components onto the PCB surface using pick-and-place machines.

- Inserting THT components through pre-drilled holes for strong mechanical connections.

- Applying different soldering techniques (e.g., reflow soldering for SMT, wave/selective soldering for THT) to ensure optimal electrical and mechanical performance.

- Final Inspection & Testing through AOI (Automated Optical Inspection) and X-ray analysis to detect soldering and placement defects.

By maintaining precise component alignment, optimized soldering processes, and stringent quality control, Mixed Technology PCB Assembly delivers reliable and high-performance circuit boards for industrial, medical, and consumer electronics.

The Key Processes in Mixed Technology PCB Assembly

Mixed Technology PCB Assembly integrates Surface Mount Technology (SMT) and Through-Hole Technology (THT) into a single hybrid PCB manufacturing process. Below is a breakdown of the essential steps to ensure high-quality and reliable PCB production.

1️⃣ Board Preparation: Ensuring a Clean PCB Surface

Before component placement, the PCB undergoes a thorough cleaning process to remove contaminants, ensuring:

✔ Strong solder adhesion for SMT components.

✔ Reliable THT solder joints, preventing oxidation or solder defects.

✔ Optimal surface preparation for precise component placement.🔹 Best Practice: PCBs should be inspected for dust, oxidation, or residual flux, and treated with anti-static measures to prevent damage to sensitive components.👉 Related Guide: Need help with PCB component identification? Check out our PCB Parts Codes Guide for better sourcing and assembly accuracy.

2️⃣ SMT Component Placement: High-Speed, Precise Assembly

Surface Mount Technology (SMT) components are placed onto the PCB surface using automated pick-and-place machines, ensuring:

✔ High-speed, precise component placement for compact and high-density PCB designs.

✔ Optimized solder joint quality using reflow soldering, where controlled heat melts solder paste to secure connections.🔹 Best Practice: Proper stencil alignment and solder paste application prevent defects like tombstoning or misalignment.

3️⃣ Wave Soldering: Securing THT Components

After Through-Hole Technology (THT) components are inserted into the pre-drilled PCB holes, the board undergoes wave soldering, where:

✔ A wave of molten solder secures the THT component leads to the PCB.

✔ This method ensures strong mechanical and electrical connections, crucial for high-power and industrial applications.

✔ Selective soldering is used for mixed assembly PCBs with both SMT and THT components to avoid overheating sensitive SMT parts.🔹 Best Practice: Proper solder temperature control prevents cold solder joints and bridging defects.

After the THT components are inserted, the PCB passes through a wave soldering process, where molten solder secures the THT component leads to the board. However, wave soldering defects such as solder bridging, cold joints, and insufficient wetting can occur if not properly controlled. Learn how to identify and fix common wave soldering issues in our guide: 👉Top 5 Common Wave Soldering Defects and How to Fix Them.

4️⃣ Inspection and Testing: Ensuring PCB Reliability

To guarantee high-quality PCB performance, the board undergoes:

✔ Automated Optical Inspection (AOI) – Detects misaligned components, solder defects, and missing parts.

✔ X-ray Inspection (for complex PCBs) – Identifies hidden soldering defects in BGA and fine-pitch components.

✔ Electrical Testing (ICT & Functional Testing) – Verifies circuit integrity, continuity, and power distribution.🔹 Best Practice: Implementing rigorous quality control at each stage ensures defect-free PCB assembly, reducing rework and failure rates.

The board undergoes thorough inspection and electrical testing to ensure that all components are properly soldered, aligned, and functional. Advanced PCB testing methods, such as Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing, help detect potential failures before mass production. Learn about the top 5 PCB testing methods used in the industry: Top 5 Testing Methods for Ensuring High-Quality PCB Assembly.

Why Choose Unit Circuits As Your Partner?

When it comes to Mixed Technology PCB Assembly, Unit Circuits is a trusted partner that offers high-quality, reliable services. Here’s why:

- Expertise in Both SMT and THT

Unit Circuits has extensive experience in both Surface Mount Technology and Through-Hole Technology. Our team can seamlessly integrate both methods to produce top-quality Mixed Technology assemblies. - Quality Assurance

We ensure the highest standards of quality through every stage of the assembly process. Our meticulous inspection and testing procedures guarantee that your PCBs will perform reliably. - Efficiency and Speed

With our advanced technology and skilled team, we can handle complex Mixed Technology assemblies with fast turnaround times, helping you get your products to market quickly. - Cost-Effective Solutions

We offer cost-effective pricing without compromising on quality. Our ability to integrate both SMT and THT in one assembly saves you time and money while delivering high-performance results.

FAQs

1.What is Mixed Technology PCB Assembly?

Mixed Technology PCB Assembly combines Surface Mount Technology (SMT) and Through-Hole Technology (THT) to enhance cost-efficiency, reliability, and performance in electronic manufacturing.

It is commonly used in industrial automation, automotive electronics, and power supply applications.

2.When should you use Mixed Technology PCB Assembly?

You should consider Mixed Technology PCB Assembly when:

- Your design requires both high-density SMT components and durable THT connectors

- Your PCB needs mechanical strength and reliability for harsh environments

- You are designing power electronics, automotive, or industrial control systems

Need a custom solution? Request a Quote Now

3.What is the difference between PCB and PCB Assembly?

A PCB (Printed Circuit Board) is a bare board with copper traces, while PCB Assembly (PCBA) refers to the process of mounting electronic components onto the PCB.

In Mixed Technology PCB Assembly, both SMT and THT components are integrated to achieve better performance, durability, and cost-effectiveness.

4.What is the SMT process?

The Surface Mount Technology (SMT) process involves:

- Solder Paste Application – A thin layer of solder is applied to the PCB

- Component Placement – Automated machines place SMT components

- Reflow Soldering – High heat melts the solder, securing the components

- Inspection & Testing – Quality control ensures a reliable assembly

Mixed Technology PCB Assembly combines this process with THT for enhanced durability.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0