Quick Leads-PCBA

PCB prototype testing is a deal breaker for your product’s success. I’ve seen countless projects delayed—or fail—because of slow turnarounds, lack of flexibility, and inconsistent test quality. That’s why a fast, low-volume, 100% quality-assured PCB testing service isn’t optional anymore—it’s a must.

PCB prototype testing services with fast turnaround and zero MOQ allow engineers to verify design accuracy, catch assembly defects early, and iterate quickly—without committing to large production runs. Using methods like AOI, ICT, and flying probe tests, these services guarantee full functionality and compliance with IPC standards. They’re ideal for startups and low-volume builds where speed, precision, and affordability make all the difference.

Let’s break down how our one-stop PCB testing and assembly service addresses your pain points—and what actually goes into functional prototype PCB testing behind the scenes.

🔧 Why Is PCB Prototype Testing Crucial Before Full Production?

Prototype testing is where mistakes meet their match. Before you spend thousands scaling production, you need to know your board works—not just electrically, but mechanically and environmentally.

Most teams I’ve worked with face these pain points:

-

Unpredictable delays from faulty designs

-

Expensive rework due to undetected soldering issues

-

Long NPI cycles caused by poor testability design

-

Lack of flexibility (especially with traditional suppliers who enforce high MOQs)

That’s why fast-turnaround PCB prototype testing isn’t just a convenience—it’s your safety net.

Case in Point: A client recently caught a power rail design issue using flying probe testing—saving them from scrapping 2,000 units later in production.

🧪 What Are the Most Common PCB Testing Methods in 2025?

Different testing methods exist for different stages of assembly. Here’s a simple breakdown of the most-used PCB testing methods:

| Testing Method | Best For | Pros | Limitations |

|---|---|---|---|

| AOI (Automated Optical Inspection) | SMT solder joints, component orientation | Fast, non-contact, high resolution | Can’t detect electrical faults |

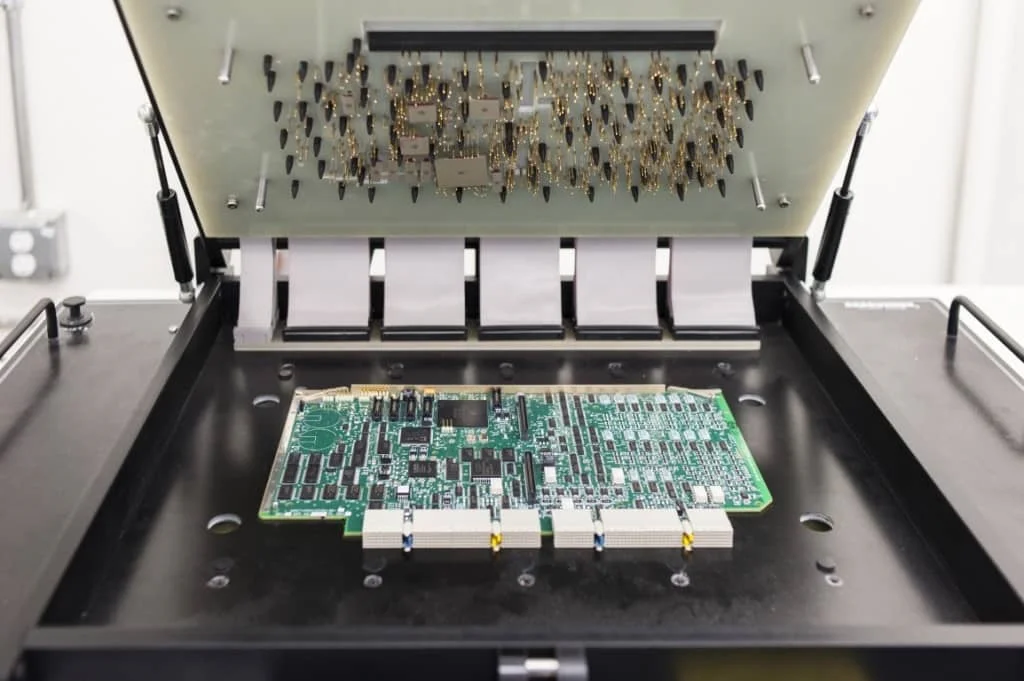

| ICT (In-Circuit Test) | High-volume production boards | Detailed electrical testing | Requires custom fixture |

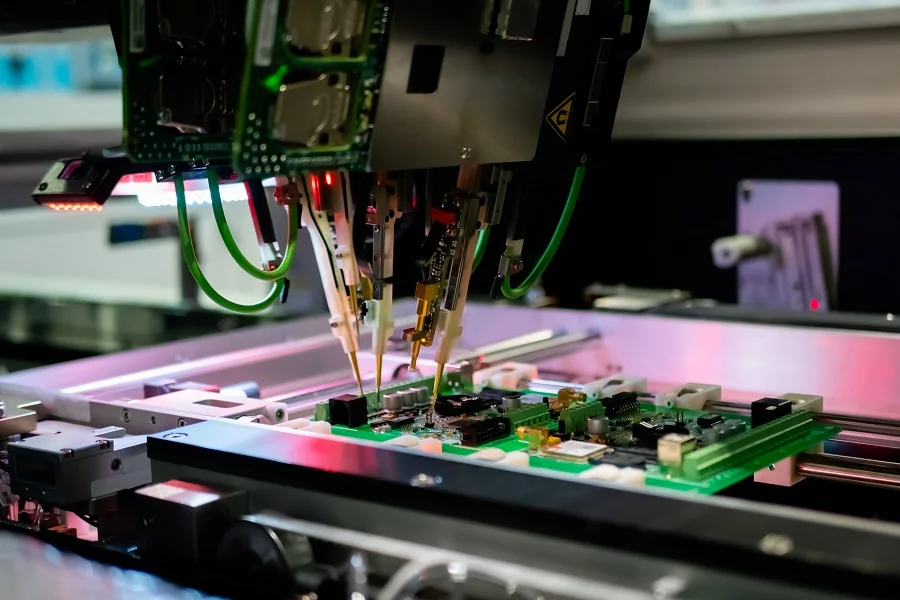

| Flying Probe Test | Prototype or low-volume testing | No fixture needed, high coverage | Slower for large batches |

| Functional Test (FCT) | Real-world performance check | Application-level verification | Needs test software + setup |

These tools—especially AOI, ICT, and flying probe—form the foundation of any robust prototype PCB assembly testing.

From AOI to ICT and functional tests, choosing the right mix of methods impacts both accuracy and speed. For a breakdown, check out our guide on the top 5 testing methods for high-quality PCB assembly.

🧰 How to Test a PCB Prototype in a Real-World Environment?

This is where Functional Testing (FCT) comes in. It simulates real usage.

When I test a PCB prototype, I usually plug it into the target application with:

-

Simulated input/output loads

-

Power cycling

-

Environmental stress (temperature, vibration)

You want the board to fail in the lab, not in the field. That’s the goal of functional PCB prototype testing.

💡 And yes, functional testing is part of our one-stop PCB assembly and testing service.

🔌 What Is Functional Testing in Prototype PCB Assembly?

Functional testing (FCT) ensures that the assembled PCB behaves as expected.

We usually run tests that mimic actual conditions:

-

Turning on/off power repeatedly

-

Sending signal patterns through I/O lines

-

Verifying MCU firmware execution

-

Testing LEDs, sensors, relays, wireless modules

🔍 We catch logic errors, voltage mismatch, and firmware issues—long before you hit mass production.

It’s essential for affordable PCB testing for prototype boards, especially if you want to go to market faster.

Functional testing simulates how the PCB will perform in real-world usage. As shown in NI’s electronics functional test strategy, this process ensures the product functions precisely as designed before scaling production.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

⚡ How Does Fast Turnaround PCB Testing Improve R&D Speed?

Speed is power in electronics development. A 24–72 hour turnaround on PCB testing means:

-

Immediate feedback on your latest iteration

-

No bottlenecks waiting for QA

-

Faster investor demos, beta releases, or Kickstarter campaigns

And for engineers under deadline pressure, this can make or break a project. Speed becomes a bottleneck if your test strategy isn’t efficient. Keysight highlights a powerful mix of ICT and functional testing in their high-volume PCBA testing solution to meet tight delivery deadlines without sacrificing quality.

📦 Low Volume PCB Prototype Testing: Is It Worth It?

Absolutely.

Here’s why low volume prototype testing pays off:

| Low Volume Testing | Mass Production Without Testing |

|---|---|

| Detects design flaws early | Risk of total batch failure |

| Enables design iteration | Stuck with defective units |

| Low cost, high return | High cost, high risk |

You’re not just “testing boards.” You’re validating your idea before committing serious money.

🔄 One-Stop PCB Assembly and Testing: Benefits for Startups

If you’re a startup, time and money are tight. That’s why you’ll benefit from a one-stop PCB assembly and testing service:

-

No back-and-forth with multiple vendors

-

Streamlined communication

-

Integrated documentation + testing reports

-

Single point of accountability

We’ve helped dozens of startups get from sketch to working prototype within 10 days. And with Zero MOQ, you’re not paying for more than you need.

💸 PCB Testing Services vs In-House: Which Is More Affordable?

Running in-house PCB testing sounds nice—until you add up:

-

Test fixture development

-

Operator training

-

AOI machine costs ($20k–$100k)

-

Flying probe equipment ($200k+)

Outsourcing gives you access to professional tools, experienced engineers, and IPC-certified testing—at a fraction of the cost.

If you’re building 5–500 units? Outsource it.

💥 Key Challenges in SMT Assembly and How Testing Solves Them

Surface Mount Technology (SMT) is fast—but unforgiving. Common issues we catch:

-

Tombstoning: Passive components stand on end during reflow

-

Solder bridging: Especially in fine-pitch ICs

-

Misaligned components: A nightmare for BGAs or QFNs

-

Cold solder joints: Not visible but deadly

That’s where AOI and x-ray inspection step in—ensuring every solder joint is up to IPC standards.

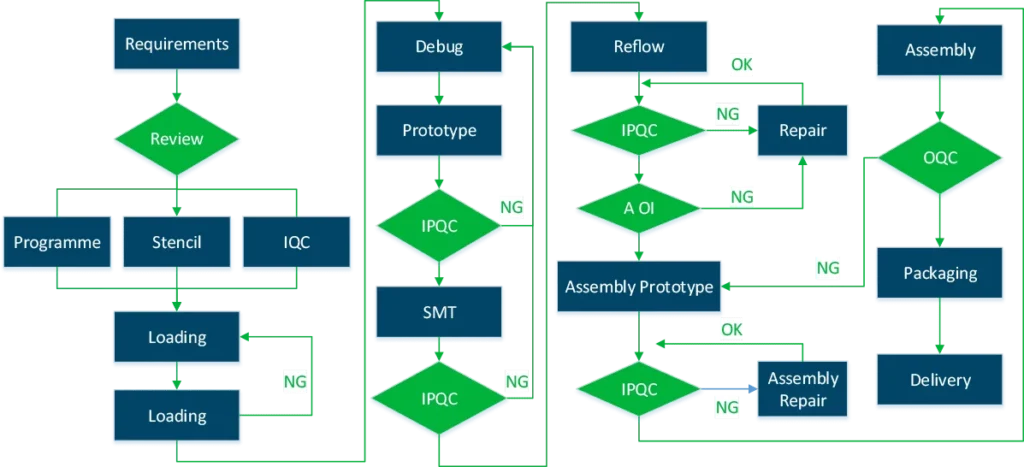

🛡️ How We Ensure PCB Prototype Quality Assurance (0 Defects)

Here’s our zero-defect strategy:

-

Design for Testability (DFT) checks during quoting

-

Automated BOM and Gerber validation

-

SMT assembly with testing via AOI and flying probe

-

100% functional testing before shipment

-

Full traceability reports and compliance certificates

And yes—every build follows IPC-A-600 Class 2/3 as per your product category.

We implement a layered inspection strategy—starting from visual checks to AOI, flying probe, and even X-ray where needed. If you’re interested in the specifics, here’s a closer look at top PCB inspection methods for ensuring PCBA quality.

📐 The Role of IPC Standards and DFT in PCB Testing Strategy

Good testing starts with smart design.

That’s why we apply Design for Testability (DFT) principles early:

-

Add test points to power rails

-

Separate analog and digital planes

-

Optimize spacing for AOI visibility

We validate designs against IPC standards before even touching a soldering iron.

🕵️ AOI vs Flying Probe vs ICT: Which Testing Method Is Best?

Here’s a simplified comparison for choosing the right method:

| Method | Best For | Speed | Cost | Coverage |

|---|---|---|---|---|

| AOI | SMT visual defects | Very fast | Low | Visual only |

| Flying Probe | Prototypes & low volumes | Medium | Medium | Excellent |

| ICT | High-volume production | Fast | High | Excellent |

If you’re testing less than 100 units, go with flying probe + AOI.

For higher volumes, consider ICT with fixtures.

🧭 Choosing the Right Turnkey PCB Testing Partner: What to Look For

Here’s your checklist:

-

✅ Zero MOQ

-

✅ Fast turnaround (1–3 days)

-

✅ SMT + test under one roof

-

✅ Support for AOI, flying probe, ICT

-

✅ IPC Class 2/3 quality standards

-

✅ Design for Testability (DFT) support

We check all these boxes—and more.

FAQs

1. What is the process of PCB validation and how does it differ from testing?

PCB validation involves confirming that a prototype meets design, functionality, and compliance goals in real-world use—not just passing basic electrical checks. Unlike standard PCB testing methods, which detect faults or assembly errors, validation examines performance under environmental stress, firmware integration, and product-specific tolerances. It’s a critical step in prototype PCB assembly testing, especially for complex products. For startups and R&D teams, this ensures your board won’t just power on—it’ll perform flawlessly where it matters.

2. What’s the difference between functional testing and in-circuit testing (ICT) in PCB assembly?

Functional testing simulates how a PCB will work in its actual product environment—powering up the board, running firmware, and checking I/O. In-circuit testing (ICT), on the other hand, checks individual components for shorts, opens, or incorrect values. ICT is better for high-volume PCB assembly, while functional testing in prototype PCB assembly is ideal for low-volume or startup scenarios where you need to validate logic and behavior more than speed.

3. How can I test a PCB for faults without expensive lab equipment?

Even without advanced tools, you can test for faults using a continuity test, multimeter probes, or test scripts via JTAG. For more thorough inspection, affordable services now include AOI, flying probe test, and low volume PCB prototype testing as part of a package—no equipment or high MOQ needed. Our one-stop PCB testing and assembly service lets you run industrial-grade diagnostics without setting up your own lab.

4. Why does design for testability (DFT) matter in affordable PCB testing?

Design for testability (DFT) improves test coverage and speeds up troubleshooting by including features like test points, clear trace spacing, and ground isolation. Without DFT, even the best PCB inspection tools may miss hidden issues. For affordable PCB testing for prototype boards, DFT can reduce testing time and costs by up to 30%. We review all designs with a DFT lens to prevent avoidable delays during testing.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🏁 Summary

If you’re building PCBs and need speed, flexibility, and guaranteed quality—without massive upfront volume—our turnkey testing and assembly service delivers. Need help? Just drop your design files, and let’s test, assemble, and iterate—fast. No MOQ. 100% functional guarantee. Let’s build better boards—together.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!