Quick Leads-PCBA

Introduction

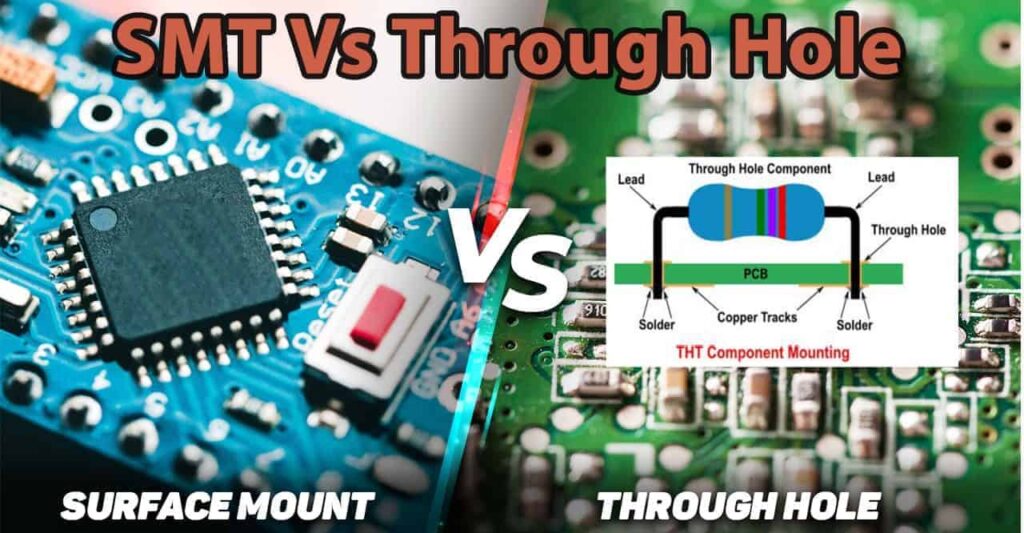

In the world of PCB manufacturing and assembly, there’s a constant debate between through-hole technology (THT) and surface-mount technology (SMT). While SMT is the go-to for miniaturized consumer electronics, through-hole PCB assembly still dominates in industries where reliability, durability, and power handling matter most.

For engineers and decision-makers sourcing PCB assembly services, choosing the right technology can make or break a project. The key pain points? Ensuring mechanical strength, managing thermal dissipation, and dealing with sourcing challenges for through-hole components in a market shifting toward SMT.

In this article, we’ll break down why through-hole PCBs are still preferred, where they are used, and how to overcome common industry challenges.

Why Use Through-Hole PCBs?

Despite SMT’s rise, through-hole technology continues to hold strong in applications where component retention, power handling, and environmental durability are critical.

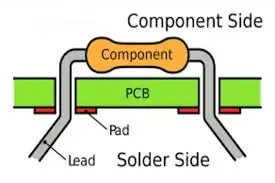

1. Superior Mechanical Strength

Unlike SMT components that sit on the surface, through-hole components are inserted into drilled holes and soldered on the opposite side. This creates a stronger physical connection, making through-hole PCBs ideal for:

- High-vibration environments (automotive, aerospace, industrial machinery)

- Devices exposed to mechanical stress (power tools, industrial automation)

- Connectors, transformers, and large capacitors that require secure mounting

For applications where mechanical strength is critical, through-hole PCB assembly ensures secure connections that SMT cannot match. This is especially important in high-vibration environments, as explained in this detailed guide by Digi-Key

2. Better Heat Dissipation & Power Handling

In power electronics applications, managing heat and current flow is crucial. Through-hole PCB assembly allows:

- Larger copper traces and vias, which improve current-carrying capacity.

- More efficient heat dissipation, making it ideal for high-power circuits and high-current applications.

- Longer lifespan of components, reducing maintenance costs.

Example: Power supply units (PSUs) in industrial automation systems often use through-hole mounting for MOSFETs and diodes to handle high current without overheating.

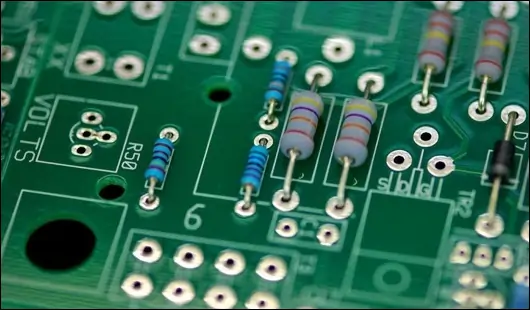

3. Easier Prototyping & Repairability

- Through-hole PCBs allow for manual soldering and component swapping, which is a major advantage for fast prototype PCB assembly with through-hole components.

- SMT solder joints are difficult to repair, whereas through-hole components can be easily desoldered and replaced.

Through-Hole PCB Applications in Different Industries

1. Industrial Electronics & Automation

- Factory automation systems, motor controllers, and PLCs require durable PCB manufacturing for long-term reliability.

- Why SMT fails? SMT components can detach due to constant mechanical movement and temperature fluctuations.

Case Study: A robotics company found that SMT resistors in their motor driver boards were failing due to vibrations. Switching to through-hole PCB assembly increased reliability by 40%.

2. Aerospace & Military Electronics

- Reliable PCB assembly for aerospace and military is crucial for high-altitude, high-G-force, and extreme temperature conditions.

- Through-hole PCBs are preferred in radar systems, avionics, and military-grade communications.

- SMT may crack under stress, while THT provides better mechanical endurance.

For high-reliability applications like military and aerospace, through-hole PCB assembly ensures long-term performance under extreme conditions. Research on through-hole PCB fabrication highlights its durability advantages over SMT in mission-critical electronics.

3. Automotive Electronics

- Durable PCB manufacturing for automotive electronics is a must for engine control units (ECUs), power distribution modules, and vehicle lighting systems.

- High power applications (ignition systems, alternators) require through-hole technology for secure electrical connections.

4. Power Electronics & High-Current Applications

- Through-hole PCBs are used in power supplies, inverters, and industrial motor drivers.

- Better thermal management allows through-hole components to handle high voltage spikes.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Through-Hole vs. Surface Mount: Key Differences

For a quick decision, here’s a comparison:

| Feature | Through-Hole PCB | Surface Mount PCB (SMT) |

|---|---|---|

| Component Size | Larger | Smaller |

| Mechanical Strength | High | Lower |

| Power Handling | Excellent | Limited |

| Heat Dissipation | Better | Requires additional cooling |

| Repairability | Easier | Difficult |

| Manufacturing Speed | Slower | Faster |

| Best For | High-reliability, high-power applications | Mass production, compact devices |

Bottom Line: Use through-hole PCBs when you need durability, power handling, and easy maintenance. Go for SMT if miniaturization and cost-efficiency are top priorities.

While surface-mount technology (SMT) is faster for large-scale production, through-hole components remain the preferred choice for prototyping and repairability. As Analog Devices explains, SMT prototyping often requires specialized tools, whereas THT allows easy manual adjustments.

Industry Challenges & Solutions in Through-Hole PCB Assembly

1. Higher Assembly Costs & Time

✅ Challenge: Through-hole PCB assembly requires manual or wave soldering, increasing labor costs.

✅ Solution: Automated selective soldering speeds up the process while keeping the soldering quality consistent.

Although through-hole PCB assembly requires more labor-intensive soldering techniques, studies have shown that it results in stronger and more reliable connections. Research on solder joint reliability in through-hole assemblies supports this, particularly in high-stress environments.

2. Component Sourcing & Lead Times

✅ Challenge: Many manufacturers are shifting away from through-hole components, making them harder to source.

✅ Solution: Custom PCB assembly with component sourcing ensures a reliable supply chain.

3. Hybrid PCB Designs (SMT + THT)

✅ Challenge: Some designs require both through-hole and SMT components, increasing complexity.

✅ Solution: Turnkey through-hole PCB solutions with fast delivery optimize performance while balancing cost.

FAQs

1. What’s the best PCB assembly method for high-power applications?

Through-hole PCB assembly is the best choice for high-power applications due to better heat dissipation and stronger solder joints. SMT components can struggle with current capacity, whereas THT can handle high voltage without reliability issues.

2. How can I speed up my through-hole PCB prototype production?

For fast prototype PCB assembly with through-hole components, working with a turnkey PCB manufacturer that handles component sourcing, soldering, and testin

3. Is through-hole PCB assembly more expensive than SMT?

Generally, yes, due to manual soldering costs. However, for low-volume, high-reliability applications, the added durability justifies the cost. If long-term reliability and ease of repair matter, through-hole is worth it.

4. What’s the best way to choose between through-hole and SMT for my project?

Consider these factors:

- If your product needs high mechanical strength, power handling, or durability, choose through-hole PCB assembly.

- If you’re designing consumer electronics, high-density circuits, or cost-sensitive products, go with SMT.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion

Even though SMT dominates modern PCB manufacturing, through-hole technology remains the gold standard for high-reliability applications. Industries like aerospace, military, automotive, and power electronics still rely on through-hole PCBs for durability, power efficiency, and mechanical strength.

If you need custom PCB assembly with component sourcing and testing, we offer the best through-hole PCB assembly service with no MOQ—perfect for low-volume, high-reliability applications.

👉 Contact us today to get expert PCB assembly solutions for your project! 🚀

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

Top 12 PCBA Manufacturers with Turnkey & Global Logistics Services [2025]

Looking for a reliable turnkey PCBA manufacturer in 2025? Discover 12 top providers with global

Box build vs PCB assembly – What’s the difference?

Understand the difference between PCB assembly and box build—explore turnkey solutions that integrate testing, wiring,

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!