Quick Leads-PCBA

Introduction: Choosing the Right PCB Assembly Method for Reliability

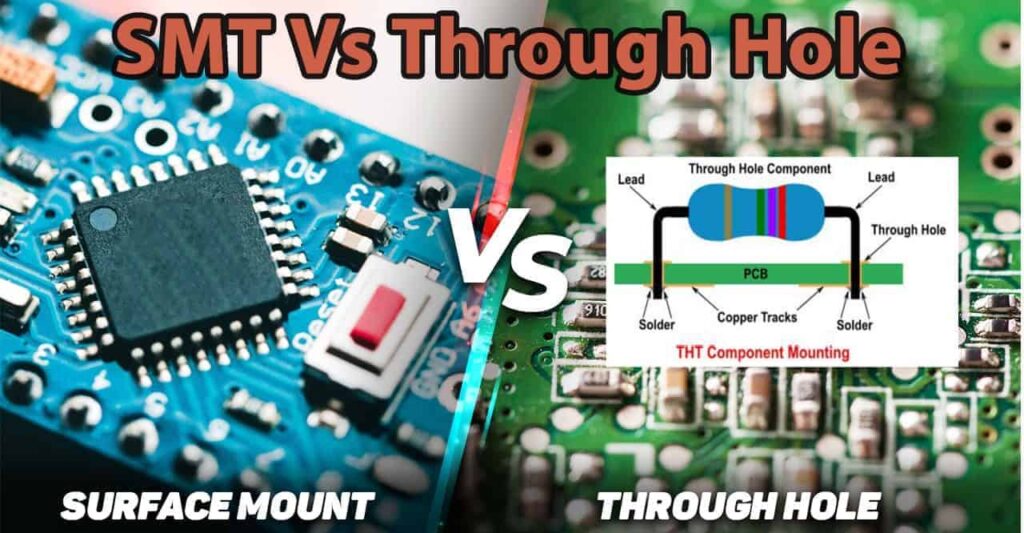

If you’re sourcing PCB assembly services, choosing between through-hole technology (THT) and surface-mount technology (SMT) is a big decision. Your choice will affect reliability, durability, and performance, especially in industrial electronics, automotive, and aerospace applications.

We all know SMT is cost-effective and great for compact designs, but is it as reliable as through-hole soldering? And when should you invest in through-hole PCB reliability instead of SMT?

Let’s break it down.

Through-Hole vs. Surface Mount: Which is More Reliable?

👉 Short answer? Through-hole PCB reliability is better for high-stress, high-temperature, and high-power applications. The components go through the board, creating a stronger bond than SMT, which relies on surface soldering.

But SMT isn’t all bad. It’s faster, cheaper, and widely used for consumer electronics, smartphones, and modern IoT devices.

So, which one should you choose? Keep reading.

1. What Is the Key Difference Between Through-Hole and Surface-Mount PCB Assembly?

Both THT and SMT are used in PCB manufacturing, but they work differently:

| Feature | Through-Hole Technology (THT) | Surface-Mount Technology (SMT) |

|---|---|---|

| Assembly Process | Components go through drilled holes and are soldered. | Components are soldered directly onto the board surface. |

| Mechanical Strength | Stronger, ideal for high-stress environments. | Weaker against vibration and mechanical stress. |

| Thermal Resistance | High – Handles heat and power better. | Lower – Solder joints can fail under extreme heat. |

| Board Size | Larger components, takes up more space. | Compact, allows for smaller PCB designs. |

| Production Cost | Higher – Slower and more labor-intensive. | Lower – Faster, automated, and cost-effective. |

| Best for… | Industrial, automotive, aerospace, military electronics. | Consumer electronics, mass production, IoT devices. |

Bottom line:

- Need durability? Go for through-hole.

- Need cost efficiency? SMT is the way.

2. Is Surface-Mount Technology More Reliable Than Through-Hole?

Honestly? Not really.

🔹 SMT reliability issues:

- Solder joints are weaker and more prone to cracks.

- Thermal cycling can cause failure (bad for automotive/aerospace).

- Not great for high-power applications.

🔹 Through-hole soldering durability:

- Stronger electrical and mechanical connections.

- Handles stress, vibration, and extreme conditions.

- Lasts longer in harsh environments.

If you’re working with high-reliability PCB assembly, THT wins—especially in power electronics, industrial machinery, and mission-critical applications.

3. Which PCB Assembly Method Is Best for High-Stress and Industrial Applications?

If your electronics face extreme temperatures, vibration, or mechanical stress, through-hole PCB reliability is the better choice.

✔ Power modules & industrial controllers (need durability)

✔ Automotive & aerospace electronics (handle heat & vibration)

✔ Medical devices & military equipment (mission-critical reliability)

SMT is great for compact, high-speed, and cost-sensitive applications, but when failure is not an option, THT wins.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

4. When Should You Use Through-Hole Components Over SMT?

Here’s when through-hole technology makes sense:

✅ When your PCB will be exposed to vibration, shock, or stress

✅ When high power or heat dissipation is needed (think power supplies)

✅ For connectors, switches, and components that need strong attachment

✅ When reliability is more important than cost

If you’re working on aerospace, industrial, or automotive projects, through-hole assembly is a safer bet.

For connectors that need to withstand repeated plugging and unplugging—such as power jacks and industrial connections—through-hole PCB reliability is far superior. According to Altium, through-hole connectors provide a mechanically stronger attachment than SMD alternatives, making them ideal for high-reliability applications.

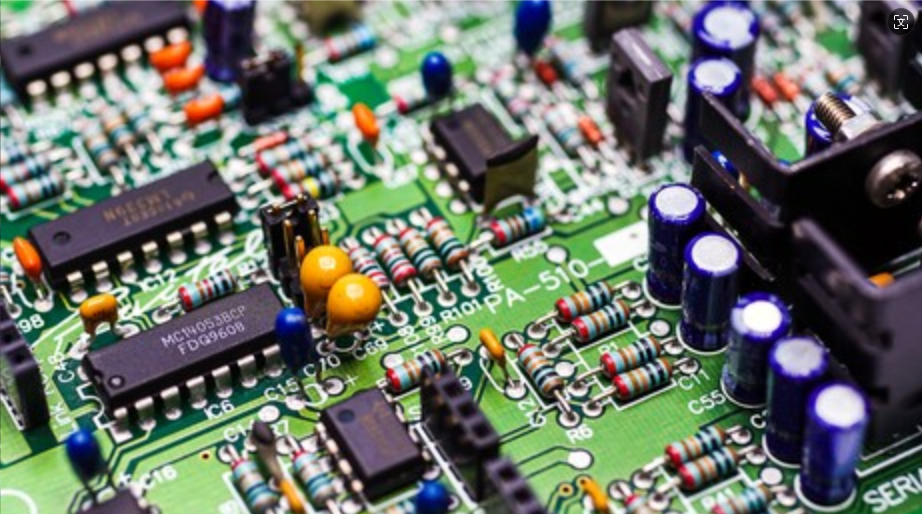

5. What Are the Common Reliability Issues in SMT and THT PCB Assembly?

📌 SMT reliability concerns:

- Cold joints & solder fatigue (fails over time)

- Tombstoning (components lift off the board)

- Bad for high-stress environments

📌 THT reliability concerns:

- More expensive & time-consuming

- Takes up more PCB space

- Not ideal for miniaturized designs

At the end of the day, it depends on your application. If reliability is a must, THT is worth the investment.

One of the key challenges with SMT reliability is solder fatigue, which can lead to electrical failures over time. Proper soldering techniques can significantly impact the durability of both THT and SMT assemblies. For an in-depth guide on best practices, check out this Digi-Key resource on soldering through-hole and surface-mount components.

6. THT vs. SMT: Durability in High-Temperature and Harsh Environments

Through-hole soldering durability is better for:

✔ Automotive electronics (heat-resistant)

✔ Power electronics (handles high currents)

✔ Aerospace applications (can withstand extreme conditions)

SMT? Not so much. It struggles with:

❌ Temperature fluctuations

❌ High-power loads

❌ Vibration and mechanical stress

When it comes to high-reliability PCB assembly, plated through-hole (PTH) technology provides stronger mechanical connections and improved power handling. This is why THT is widely used in aerospace, automotive, and industrial electronics. Learn more about the advantages of plated through-hole PCBs in this Altium guide.

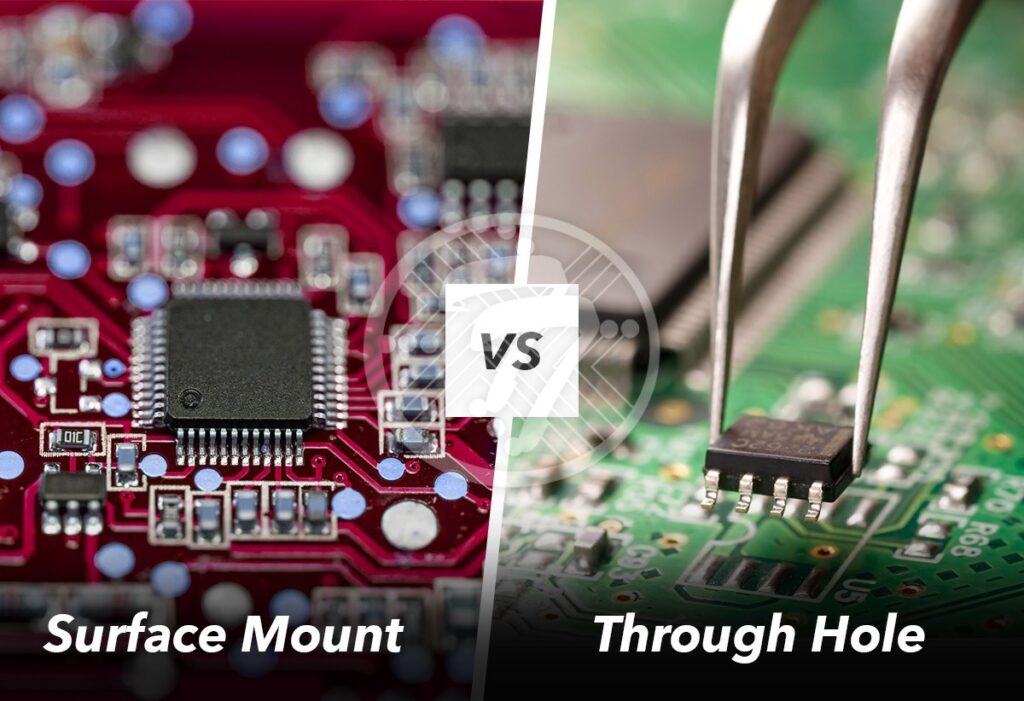

7. How to Choose Between Through-Hole and SMT for Your Electronics Assembly?

Ask yourself:

🤔 Will the PCB face extreme conditions? → Go THT

🤔 Do you need cost efficiency and automation? → Go SMT

🤔 Are you dealing with high power or mechanical stress? → Go THT

Many manufacturers use a hybrid approach:

- Critical components → Through-hole

- Space-sensitive components → SMT

This gives you the best of both worlds.

8. The Future of Through-Hole Technology: Is It Still Relevant?

Even though SMT dominates mass production, through-hole components are still used in:

✔ Military & aerospace applications

✔ High-reliability industrial equipment

✔ High-power electronics

With new automation techniques, THT remains essential in high-reliability PCB assembly.

FAQs

1. Is Through-Hole PCB More Durable Than SMT?

Yes! Through-hole PCB reliability is superior for mechanical strength, heat resistance, and durability in harsh environments. That’s why it’s used in automotive, aerospace, and industrial electronics.

2. Which PCB Assembly Method is Best for Heavy-Duty Applications?

THT is the best choice for high-reliability PCB assembly, especially in power electronics, military equipment, and industrial automation where components must withstand extreme stress.

For industrial-grade PCBs, where connectors experience mechanical stress and need secure mounting, through-hole mounting remains the best option. According to Digi-Key, through-hole connectors ensure better durability and electrical stability compared to surface-mount alternatives.

3. Is There a Fast PCB Prototyping Service for Through-Hole & SMT?

Yes! We offer fast PCB prototyping with through-hole and SMT components, ensuring high-reliability assembly with no MOQ (minimum order quantity).

4. When to Use Through-Hole Over SMT in PCB Design?

Use THT when reliability is more important than cost—for example, in power circuits, industrial control systems, and mission-critical applications where durability matters more than PCB size.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion: Which PCB Assembly Method Is More Reliable?

If you need high-reliability PCB assembly, through-hole PCB reliability is the better choice. It may be slower and more expensive, but it lasts longer, handles stress better, and ensures stronger connections.

Looking for high-reliability PCB assembly services with no MOQ? We offer fast prototyping with both SMT and THT components. Let’s talk!

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!