Quick Leads-PCBA

Sourcing PCBA Services Shouldn’t Be This Hard.

If you’re in charge of sourcing PCBA for OEM electronics, you’ve probably hit a few walls: inconsistent quality, unclear pricing, or delays that cost more than just time. I’ve been there. That’s why I’ve pulled together a list of 2025’s top 15 full-service PCBA suppliers that can actually deliver — with global logistics, testing, certifications, and real experience in OEM product development.

The top 15 full-service PCBA suppliers for OEM electronics in 2025 include trusted names like Jabil, Sanmina, Flex, and Unit Circuits. These companies offer turnkey PCB assembly, component sourcing, testing, packaging, and global delivery. Whether you need prototype-to-production scalability, RoHS-compliant processes, or box build services, these suppliers deliver dependable results across consumer, industrial, and medical electronics markets.

Let’s break this down — what “full-service” actually means, why most projects fail without it, and how to choose the best turnkey PCBA supplier for your OEM needs.

What is a Full-Service PCBA Manufacturer — and Why It Matters

When people say “full-service,” they often just mean assembly. But a true full-service PCBA manufacturer does a lot more:

-

PCB fabrication

-

Sourcing and managing your BOM

-

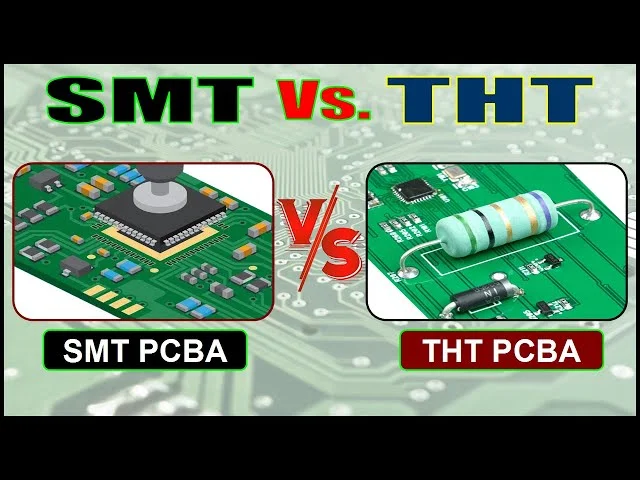

SMT and THT assembly

-

Functional testing (FCT)

-

Box build and logistics

-

Compliance with RoHS, ISO, or IPC standards

Why does this matter? Because if even one part of that chain breaks, your product is delayed. And worse — your customers notice.

📊 What’s Included in a “Full-Service PCBA”

| Feature | Basic PCBA | Full-Service PCBA |

|---|---|---|

| PCB Fabrication | ✔️ | ✔️ |

| Component Sourcing | ❌ | ✔️ |

| SMT & THT Assembly | ✔️ | ✔️ |

| Functional Testing (FCT) | ❌ | ✔️ |

| Box Build & Packaging | ❌ | ✔️ |

| Global Logistics | ❌ | ✔️ |

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Key Pain Points in OEM Electronics PCBA Sourcing

Even the best electrical engineers and hardware developers face common bottlenecks:

-

🔍 Inconsistent sourcing quality: Wrong parts, late parts, or non-compliant parts ruin builds.

-

⌛ Long lead times: A 10-week delay kills product launch momentum.

-

🧾 Cost blowouts: BOM cost optimization is rarely a priority at some suppliers.

-

⚠️ Low visibility: No transparency in testing, yield rates, or logistics.

-

💬 Poor communication: Language barriers + time zones = delays and rework.

This is where turnkey PCBA suppliers come in. They manage your electronics supply chain, from sourcing to shipping — so you don’t have to.

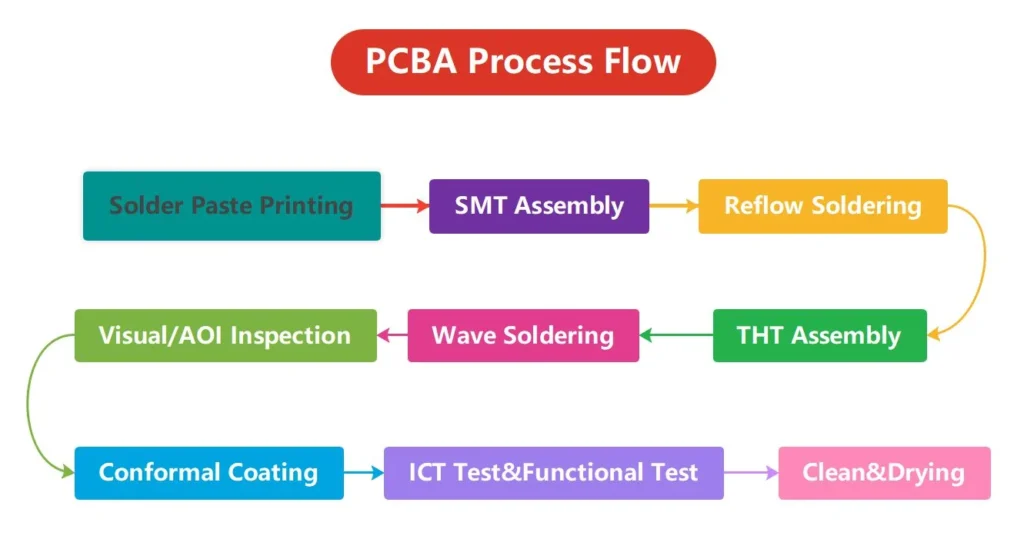

How Turnkey PCB Assembly Works (And Why It Saves You Time)

Turnkey PCB assembly service for OEM means you send your files, and they deliver finished, tested assemblies — ready for integration. No component sourcing, no supplier juggling, no headaches.

Here’s how it typically flows:

-

You submit Gerber + BOM + test plan.

-

They handle PCB fab, sourcing, DFM checks.

-

SMT/THT processes run.

-

FCT, visual, and AOI testing complete.

-

Product is boxed, packed, and shipped.

It’s ideal for small startups and global OEMs alike. Need low MOQ PCB assembly or RoHS-compliant PCB assembly from China? A full-service EMS partner handles it all.

Turnkey PCB assembly simplifies your workflow by bundling fabrication, sourcing, assembly, and testing. If you want to understand how this model cuts costs and time-to-market, this in-depth guide explains the business benefits clearly.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Technical Challenges in PCBA — And How Top Suppliers Solve Them

Let’s talk about real problems in PCBA and how top turnkey PCBA suppliers solve them.

🛠️ Challenge 1: BOM Cost Optimization

Poor sourcing = high cost. Smart suppliers use strategic sourcing, offer DFM feedback, and suggest alternate components — saving 5–20% on average.

🛠️ Challenge 2: Lead-Free Soldering

If you’re targeting EU markets, RoHS compliance is non-negotiable. Suppliers like Unit Circuits provide lead-free soldering services that meet EU RoHS requirements.

🛠️ Challenge 3: Testing

Good suppliers do functional testing (FCT), not just visual inspection. This includes powered tests, IC programming, and even thermal profiling.

What to Look for in a Reliable PCBA Partner

It’s not just about the lowest quote. A real OEM PCBA manufacturer should provide:

-

📋 Certifications: ISO 9001, ISO 13485, RoHS, IPC-A-610

-

🔬 Testing Infrastructure: AOI, X-ray, FCT

-

📦 Box Build & Packaging: Final assembly and product labeling

-

🚚 Logistics & Warehousing: Especially if you serve UK electronics importers or EU markets

📊Lead Times, Services, and Certifications

| Supplier | Lead Time | Services | Certifications |

|---|---|---|---|

| Unit Circuits | 7–15 days | Turnkey, Testing, Box Build | ISO 9001, RoHS |

| Jabil | 10–20 days | Full EMS, Global Warehousing | ISO, UL, ITAR |

| Flex | 12–25 days | Design, EMS, Packaging | ISO 13485, IATF |

| Plexus | 15–28 days | DFX, Validation, Test Engineering | FDA, ISO 13485 |

Top 15 Full-Service PCBA Suppliers for OEM Electronics in 2025

Let’s get to the list. Based on capability, reputation, technical support, and compliance readiness.

1. Jabil Inc. – USA

Known for: Electronics contract manufacturing, enterprise-grade testing, and supply chain integration.

2. Sanmina Corporation – USA

Known for: Serving aerospace, automotive, and medical electronics with high-compliance builds.

3. Flex Ltd. – Singapore

Known for: Complex projects with global distribution and sustainable electronics manufacturing.

4. Plexus Corp. – USA

Known for: Helping startups transition from prototype to production PCBA at scale.

5. Benchmark Electronics – USA

Known for: High-reliability solutions with advanced FCT, burn-in, and RF testing.

6. Unit Circuits – China 🇨🇳

If you’re sourcing from China and need a one stop PCBA supplier for consumer electronics, Unit Circuits is worth a look.

They specialize in:

-

Turnkey electronics production for OEMs

-

Box build and packaging

-

Design-for-Manufacturing (DFM) support

-

Global shipping electronics, including to the UK and EU

-

Lead-free PCB process to meet RoHS requirements

Whether you’re a startup or a large OEM looking for a Chinese PCBA supplier for UK electronics importers, Unit Circuits bridges quality with cost-efficiency.

7. Creation Technologies – Canada

Known for: Excellent customer service and NPI support for medical and industrial electronics.

8. Zhen Ding Tech – Taiwan

Known for: High-volume flex PCBs and rigid-flex for wearables and mobile devices.

9. Fabrinet – Thailand

Known for: Optical, industrial, and automotive assemblies, and BOM cost optimization.

10. Venture Corp – Malaysia

Known for: Scalable EMS, PCB component sourcing, and box build integration.

11. SIIX Corporation – Japan

Known for: Multilingual support, strict compliance, and cross-border supply chain management.

12. Kitron – Norway

Known for: Serving EU-based OEMs with traceability and functional testing (FCT).

13. Wistron NeWeb – Taiwan

Known for: RF modules, IoT, and networking products with mass production capabilities.

14. Asteelflash (USI) – France/Global

Known for: Automotive-grade EMS with robust RoHS/ISO certified EMS credentials.

15. Vicor Corporation – USA

Known for: Power modules and low MOQ PCB assembly for niche industrial needs.

What Sets Unit Circuits Apart from Other Chinese EMS Providers?

While many claim to offer turnkey service, Unit Circuits delivers on:

-

Component sourcing & global logistics under one roof

-

Surface mount assembly (SMT) for precision builds

-

Prototyping + production runs with scalable pricing

-

Packaging and custom box build integration

-

Design support with DFM review so you avoid rework

They’re a full service electronics manufacturing company in China that doesn’t just say “yes” — they make it happen.

Tips for Importers: Managing Risk When Sourcing from China

If you’re a UK or EU importer, here’s how to stay safe:

-

Work only with RoHS-certified partners

-

Ask for lot traceability and full COC

-

Choose a partner offering functional testing and DFM insights

-

Clarify logistics responsibilities upfront

A good Chinese PCBA supplier for UK electronics importers will handle customs, labeling, and EU-friendly shipping standards.

FAQs

1. How to choose the best PCBA supplier for electronic devices?

Start by checking if the PCBA company offers full-service capabilities—turnkey PCB assembly, component sourcing, testing, and global logistics. Look for certifications like ISO 9001 or RoHS compliance, plus support for low and high volumes. A reliable electronics supply chain partner should provide clear DFM feedback, fast lead times, and transparent communication from prototype to mass production.

2. Which country makes the most circuit boards and PCBA products?

China leads globally in both PCB fabrication and turnkey electronics production. A PCBA manufacturer in China can typically offer competitive pricing, advanced SMT capabilities, and lead-free PCB assembly that meets EU RoHS standards. This makes China the top choice for importers from Europe, North America, and Asia—especially for OEM electronics assembly service.

3. Are PCBs and PCBAs still widely used in the United States?

Absolutely. While many companies source production offshore, the U.S. remains home to top electronics contract manufacturing firms like Jabil and Sanmina. These OEM PCBA manufacturers serve defense, medical, and aerospace sectors that require local, certified, and highly traceable manufacturing. Even startups in the U.S. often partner with domestic firms for prototype to production PCBA cycles.

4. Does JLCPCB do turnkey PCBA services?

Yes, JLCPCB offers turnkey PCBA services for OEM clients, including PCB fabrication, component sourcing, and surface mount assembly (SMT). They are popular for low-cost prototyping and small-volume builds. However, for more complex projects—like those needing functional testing, box build, or strict quality certifications—OEMs may prefer a more comprehensive full-service electronics manufacturing company in China like Unit Circuits.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

How to Work with a One-Stop PCBA Supplier for Consumer Electronics

Working with a one stop PCBA supplier saves you time and money — but only if they:

-

Understand your end-product requirements

-

Handle component alternates without downgrading quality

-

Offer transparent production and testing reporting

-

Help reduce your time-to-market

This is where full-service providers like Unit Circuits, Jabil, and Flex give you the edge.

Final Thoughts

Choosing the right OEM PCBA manufacturer makes or breaks your product timeline and quality. Hopefully, this list gave you clarity. If you’re scaling or prototyping in 2025, it pays to partner with a supplier who understands design, logistics, and quality. Let’s build smarter, together.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!