Quick Leads-PCBA

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Modern electric motor controllers power everything from EVs and robotics to factory automation. But sourcing high-performance PCB assemblies for motor control applications remains a major challenge. Inconsistent quality, long lead times, and high MOQs are still common — and costly.

In this article, we’ll explore the top 10 PCB assembly companies in 2025 that are solving these issues with technical expertise, fast delivery, and turnkey services. Whether you’re building a high-power driver or a smart actuator controller, this guide will help you choose the right partner.

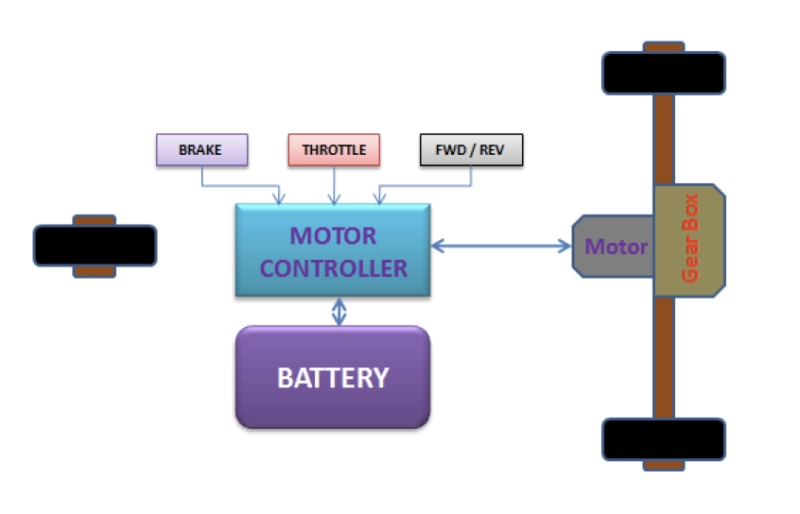

⚡ What is an Electric Motor Controller and Why Does It Need PCB Assembly?

An electric motor controller regulates the performance of motors in response to inputs like torque, position, and speed. Whether it’s a simple brushed DC setup or a sophisticated field-oriented control (FOC) system in EVs, the PCB (Printed Circuit Board) lies at its core.

These controllers typically include:

-

Power stages (MOSFETs or IGBTs)

-

Gate drivers

-

Microcontrollers or DSPs

-

Position and current sensors

-

EMI filtering and thermal pads

That’s why PCB assembly for electric motor controllers isn’t just component placement — it’s precision engineering.

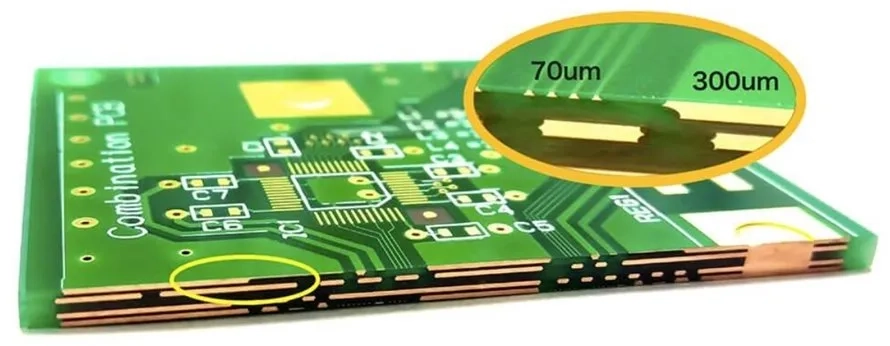

🛠️ What Makes PCB Assembly for Electric Motor Controllers So Challenging?

Motor controller PCB assembly demands a higher level of technical accuracy than standard boards. Here’s why:

-

High-current paths must be routed with proper copper thickness and spacing.

-

Thermal management is critical in continuous-duty applications.

-

EMI/EMC compliance requires careful layer stack-up and shielding.

-

Sensor precision depends on low-noise analog signal routing.

-

Compact footprints increase assembly difficulty for power-dense boards.

These pain points are especially common when using generic PCB assemblers not specialized in motor control systems.

⚙️ How PCB Assembly Enhances Electric Motor Driver Performance

A reliable motor controller relies on more than just the schematic. The manufacturing process must preserve signal integrity, power distribution, and long-term reliability.

This includes:

-

Controlled impedance for communication lines (CAN, SPI, UART)

-

Reflow soldering for high-current pads

-

AOI (Automated Optical Inspection) for SMT defects

-

In-circuit or functional testing post-assembly

Choosing a turnkey PCB assembly electric motor provider ensures all of this is handled under one roof — from prototyping to testing.

The performance of a motor driver is directly tied to how the PCB is assembled — everything from reflow profiles to component alignment impacts efficiency and EMI. For a complete breakdown of how these stages interconnect, read the 10 essential steps in PCB assembly for professionals.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

🌍 Top 10 PCB Assembly Companies for Electric Motor Controllers in 2025

Here’s our global list of the most reliable companies for PCB manufacturing for motor control systems — based on technical capabilities, delivery speed, compliance, and customer support.

1. TTM Technologies (USA)

-

Known for: Aerospace-grade PCBs and industrial control applications

-

Capabilities: Rigid-flex boards, thermal vias, conformal coating

-

Ideal for: High-reliability motion control and electric drive systems

Learn More

2. Nippon Mektron (Japan)

-

Known for: Precision FPC/PCB assemblies for automotive and robotics

-

Strengths: Flex-rigid hybrids, automotive-grade reliability

-

Ideal for: Embedded motor control PCB in automotive applications

Learn More

3. Viasion Technology (China)

-

Known for: Small to mid-volume PCBA with fast turnaround

-

Services: PCB prototyping electric actuators, low-volume production

-

Ideal for: Startups needing quick iteration in motor driver design

4. Compeq Manufacturing (Taiwan)

-

Known for: Multi-layer and HDI PCB fabrication for industrial motors

-

Certifications: ISO 9001, IATF 16949

-

Ideal for: High power PCB assembly for motor applications

5. Jabil Circuit (USA)

-

Known for: Global EMS, from PCB fabrication to full box build

-

Focus: Turnkey electronics manufacturing for motion control

-

Ideal for: OEMs scaling smart motor controller PCBs

6. Unit Circuits (Global HQ in Shenzhen, China)

-

Known for: Motor control PCB specialization with rapid delivery

-

Standout Features:

-

No MOQ pcb manufacturer for electric motors

-

Fast pcb prototyping electric motor controller boards

-

In-house testing for pcb assembly with actuator control

-

RoHS, ISO, and CE compliance

-

-

Ideal for: Prototyping and production of custom pcb for electric actuator control

Learn More 🔗

7. PCBWay (China)

-

Known for: Affordable and customizable PCB assembly services

-

Services: Prototyping, small-batch runs, and design for manufacturability

-

Ideal for: Cost-effective electronic speed controller pcb builds

Learn More

8. Sanmina Corporation (USA)

-

Known for: High-end industrial automation PCB assembly

-

Strengths: Embedded component assembly, 3D X-ray inspection

-

Ideal for: Critical systems needing high fault tolerance

9. Shenzhen Fastprint Circuit Tech (China)

-

Known for: Speed and accuracy in batch PCB production

-

Focus: High-frequency, multilayer designs for servo control

-

Ideal for: Motion control circuit board assembly with tight tolerances

10. Unimicron Technology (Taiwan)

-

Known for: Leading PCB fabrication for intelligent motor systems

-

Edge: Focus on automotive and smart home actuators

-

Ideal for: Scalable and customizable PCB assembly for industrial motors

📥 Want a printable comparison of all 10 vendors + expert checklists for sourcing motor controller PCBs?

🥇 Why Unit Circuits Ranks #6 for Motor Control PCB Assembly

Unit Circuits earned its spot for delivering technical excellence without the barriers of high MOQs or slow delivery. Whether you’re an R&D engineer needing a custom PCB for electric actuator control or an automation company scaling a motor driver series, they offer:

-

No-MOQ production

-

Fast turnaround (<7 days)

-

Functional testing included

-

BOM optimization support

-

Multi-market compliance (RoHS, REACH, CE)

Their turnkey solution simplifies the entire process — from design review to post-assembly testing — making them a go-to choice for embedded motor control PCB projects.

🔍 What is the Best PCB Company in 2025?

There’s no one-size-fits-all. The best PCB company depends on your needs:

-

Need speed? Go with Viasion or Unit Circuits.

-

Want domestic support? Choose TTM or Sanmina.

-

Require automotive-grade quality? Consider Nippon Mektron or Unimicron.

What matters is that your supplier understands the demands of motion control and can support both prototyping and scaling.

🇺🇸 Are There Any PCB Assembly Companies in the USA or Europe?

Yes! Here are some reliable ones:

-

TTM Technologies – USA (top-tier for motion control systems)

-

Sanmina – USA (industrial and medical-grade builds)

-

Jabil – Global (OEM-grade EMS with robust capabilities)

-

Sierra Circuits – USA (low-volume prototyping)

These offer faster shipping, local support, and stronger IP protection — ideal for high-stakes industries.

🔄 PCB Manufacturing Trends in Motor Control and Industrial Automation

In 2025, we’re seeing a shift toward:

-

Embedded motor control PCB for robotics and smart machines

-

Compact, high-efficiency motor driver PCBs

-

PCB assembly services tailored for industrial automation

-

Rise of high-voltage actuator drivers in EV and HVAC sectors

This is where LSI keywords like electronics manufacturing for electric motors and motor control unit PCB fabrication naturally align.

🧪 Choosing Between Low-Volume & High-Volume PCB Assembly for Electric Motors

If you’re in R&D or low-volume production, look for:

-

Low volume pcb assembly for motor control

-

Fast pcb prototyping electric motor controller

-

No MOQ pcb manufacturer for electric motors

For scaling, prioritize:

-

Batch pricing

-

Panelization support

-

Compliance (UL, CE, ISO)

🔍 What to Look for in a PCB Assembly Partner for Motion Control

Here’s your checklist:

-

Turnkey electronics manufacturing for motion control

-

In-house testing (functional + visual)

-

BOM optimization and DFM feedback

-

IPC Class 2/3 workmanship

-

Fast iteration cycles

Use this to avoid delays, quality failures, or poor support in the long run.

⏱️ How Fast Can You Prototype a PCB for Electric Motor Drivers?

Companies like Unit Circuits, PCBWay, and Viasion now offer:

-

Fast pcb prototyping for electric motor controller boards

-

<7-day delivery with functional testing

-

Quick-turn sample runs with high copper weight

This is perfect for validating designs in applications like:

-

Smart actuators

-

Servo drives

-

BLDC controllers

-

Stepper drivers

🔧 How Does Testing Ensure Reliability in Actuator PCB Assembly?

Testing = trust in motion control.

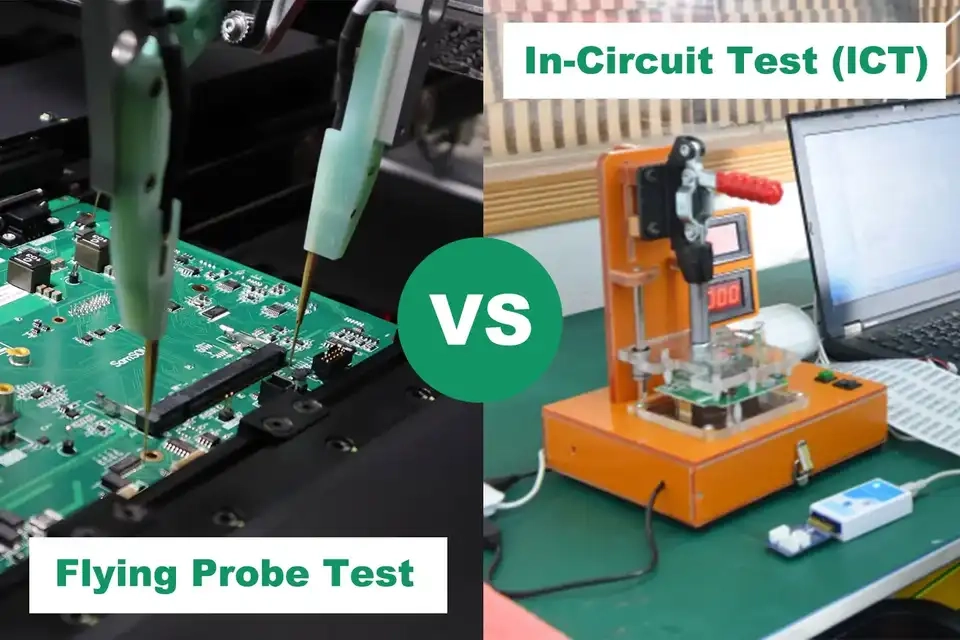

Leading companies now integrate:

-

PCB assembly with testing for actuator control

-

ICT (In-Circuit Testing) for shorts and opens

-

Functional test jigs for live power testing

-

Thermal cycling and vibration screening

If you’re deploying in industrial or transport environments, this is non-negotiable. Functional testing and AOI are non-negotiable when it comes to motion systems. If your actuator control PCB fails under load, you’re looking at not just downtime, but potential mechanical failure. For a deep dive into the most reliable validation techniques, see the top 5 testing methods for ensuring high-quality PCB assembly used by industry leaders.

FAQs

1. Is low volume PCB assembly viable for motor control applications?

Yes, especially in 2025. Many suppliers now offer low volume PCB assembly for motor control systems without compromising on quality or speed. This is ideal for prototyping or small-batch production of electric actuators and motor drivers. Look for providers with no MOQ policies, fast

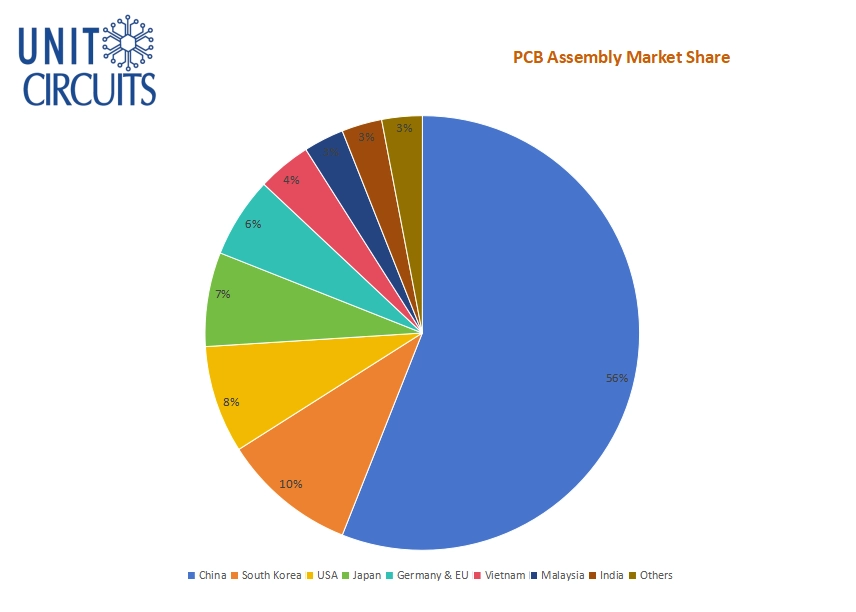

2. Which country leads in turnkey PCB assembly for motion control?

China continues to dominate in turnkey PCB assembly for motion control, offering competitive pricing, full-process integration, and export-ready compliance. However, companies in the USA and Germany are gaining ground in high-reliability applications, especially in automotive and industrial automation. Choosing a partner with both engineering support and international certifications ensures performance and scalability.

3. How can I find a customizable PCB assembly service for industrial motors?

You’ll want a provider offering customizable PCB assembly for industrial motors, which includes support for component selection, stack-up engineering, and layout optimization. This service is crucial for motor control PCBs where EMI, thermal loads, and current routing require custom design rules. Look for vendors with in-house DFM review and industrial compliance expertise.

4. What trends are shaping the PCB market for electric motors in 2025?

In 2025, the PCB market for electric motors is shifting toward high power PCB assembly, modular controller design, and integration with IoT systems. More companies now require pcb fabrication and assembly for automation devices that can handle higher currents and tighter spaces. Demand for intelligent motor systems and embedded sensing is also driving rapid innovation.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

🧾 Summary

Choosing the right PCB assembly company can make or break your next electric motor controller project. The top 10 companies listed here combine speed, precision, and expertise in motion control PCB design.

Looking to prototype or scale up?

Reach out to a company like Unit Circuits for a fast, reliable, and customizable solution.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

Top 12 PCBA Manufacturers with Turnkey & Global Logistics Services [2025]

Looking for a reliable turnkey PCBA manufacturer in 2025? Discover 12 top providers with global

Box build vs PCB assembly – What’s the difference?

Understand the difference between PCB assembly and box build—explore turnkey solutions that integrate testing, wiring,

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!