Quick Leads-PCBA

What’s the deal with silkscreen on a PCB? It seems simple — just text and lines, right? But for engineers, technicians, and anyone sourcing PCB assembly services, silkscreen is mission-critical. When it’s wrong, you get delays, costly mistakes, and rework nightmares. When it’s right? You get smoother assembly, faster QA, and fewer support tickets.

What Is Silkscreen on a PCB?

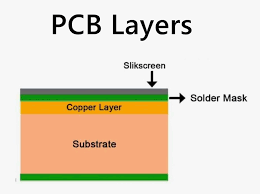

Silkscreen is a printed layer on the surface of a PCB that uses ink to display critical information — like component identifiers, polarity marks, test points, and logos. It’s typically applied to the top (component) side of the board, and sometimes the bottom, using screen printing, LPI, or inkjet methods.

Let’s dig deeper — because what looks like “just labels” actually plays a massive role in performance, manufacturability, and even cost.

What Is a Silkscreen in PCB?

The PCB silkscreen (also called the overlay) is a graphical layer printed on the outer surface of a board. It doesn’t conduct electricity — it’s purely for communication. Think of it as the labeling system for your circuit board.

🧰 What’s Printed in the Silkscreen?

-

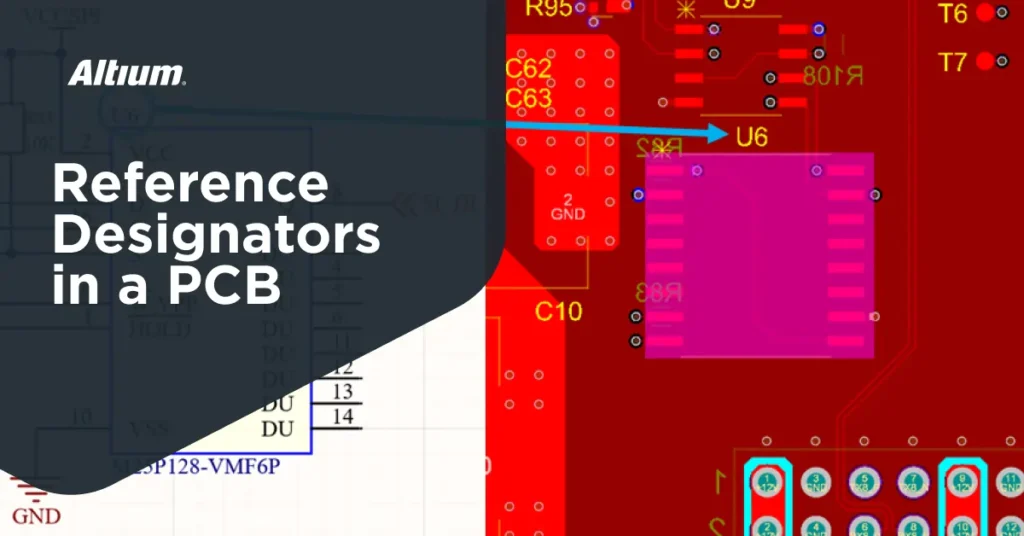

Reference designators (e.g., R1, C2, U3)

-

Component outlines and pin 1 indicators

-

Polarity markers (for LEDs, diodes, ICs)

-

Test point identifiers

-

Board part number, version, and date

-

Company logos, warnings, and certifications

The silkscreen helps everyone — from the assembly line to tech support — quickly understand your board.

What Is the Purpose of a Silkscreen in PCB?

If you’re asking why silkscreen matters, here’s what it does:

| Purpose | Why It Matters |

|---|---|

| Component identification | Speeds up assembly & inspection |

| Polarity marking | Prevents catastrophic reverse installation |

| Maintenance & repair aid | Helps with debugging, soldering, and field support |

| Quality assurance reference | Guides AOI and manual inspection |

| Brand identity & compliance | Shows logos, warnings, certs like RoHS/UL |

TL;DR: Silkscreen is your assembly manual, printed directly onto the board.

Silkscreen Layer in PCB Design: What Goes Where?

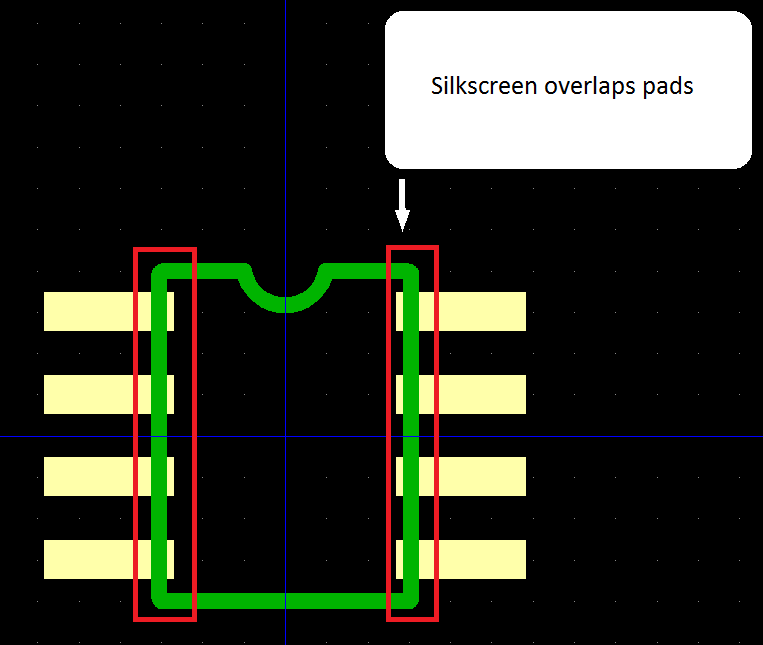

Most PCBs have silkscreen on the top layer, though double-sided silkscreen is used for complex boards. Placement is critical — silkscreen should never touch pads or vias.

🧠 Key Elements in the Silkscreen Layer:

-

Reference Designators: R5, C7, D1, U2…

-

Component Outline: To assist in orientation

-

Pin Indicators: Especially for polarized parts

-

Text Fonts: Use sans-serif, minimum 5 mils (but 7+ is safer)

-

Board Info: Name, version, job number

We follow IPC-2615 standards to ensure clarity, durability, and manufacturability.

For best practices on component outlines, font sizing, and placement, Altium’s PCB silkscreen guidelines offer a solid reference backed by industry standards.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Overlay vs Silkscreen – Are They the Same?

Yes and no. “Overlay” is often used in CAD tools (Altium, KiCad, Eagle) to describe the design layer, while “silkscreen” refers to the actual printed output during fabrication.

| Term | Context | Meaning |

|---|---|---|

| Overlay | CAD Design | Layer where text/graphics are placed |

| Silkscreen | PCB Manufacturing | Printed ink layer on PCB surface |

In sourcing, always clarify what your vendor means — because “overlay” might confuse buyers unfamiliar with PCB jargon.

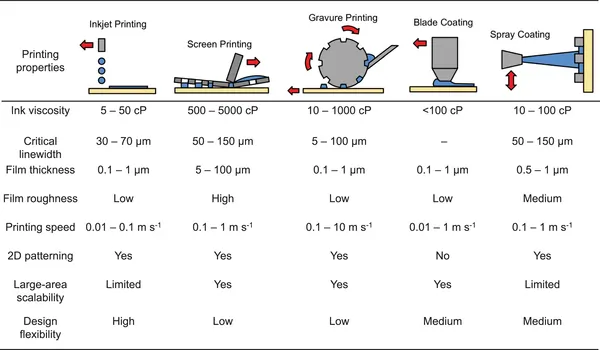

Silkscreen Printing in PCB Assembly – Methods & Machines

Silkscreen is printed after solder mask but before component assembly. Here’s how it’s done:

| Method | Description | Pros | Cons |

|---|---|---|---|

| Manual Screen Printing | Mesh stencil + ink for basic boards | Cheap, easy setup | Low resolution, labor-heavy |

| Liquid Photo Imaging (LPI) | Uses photosensitive ink and UV light | Sharp detail, reliable | Slower, more costly setup |

| Direct Legend Printing (DLP) | Inkjet prints legends directly from digital files | Fast, accurate, flexible | Requires specialized machines |

We use LPI and DLP depending on board complexity and volume — no one-size-fits-all approach here.

To avoid common pitfalls like illegible fonts or ink misalignment, Cadence’s layout rules provide detailed specs on font sizes, clearances, and line width standards.

Industry Pain Points: Why Silkscreen Is Often Overlooked

Many PCB designs we receive have silkscreen issues that cost real time and money:

❌ Common Industry Issues

-

Missing silkscreen layer in Gerbers

-

Poor readability (tiny fonts, low contrast)

-

Text on pads = ink contamination

-

Layer mismatch with solder mask

These problems cause delays in production or worse — a failed assembly run. When silkscreen is treated like an afterthought, assembly teams are flying blind.

Our Solution: Smart Silkscreen That Solves Real Problems

We’ve designed our silkscreen process around real-world PCB challenges — not just pretty graphics.

✅ What We Offer:

-

No MOQ PCB silkscreen: From one-offs to mass runs

-

Custom silkscreen for branding & compliance

-

Gerber review service: We fix silkscreen placement BEFORE fabrication

-

Readable, production-friendly labeling using LPI or DLP

📌 Looking for a reliable, custom PCB silkscreen service in China? We’ve got you covered — with full DFM support.

Silkscreen and the PCB Assembly Process: A Designer’s Perspective

From an assembly line standpoint, clear silkscreen means:

-

Easier SMD placement (both manual and automated)

-

Fewer component swaps or polarity mistakes

-

Faster AOI validation

-

Quicker rework and repair in prototyping

Silkscreen is more than a cosmetic layer — it’s a productivity enhancer. During PCB assembly, a clear and accurate silkscreen layer enhances every phase — from visual inspection to AOI and functional testing. To see how silkscreen complements quality checks, explore our breakdown of the top 5 testing methods used in PCB assembly and why visual cues still matter.

Designing for Readability: Fonts, Colors, and Clarity

Here’s where a lot of boards fall short. Too small, too crowded, or not visible enough.

🎨 Common Silkscreen Ink Colors:

-

White (most common)

-

Yellow (on black solder mask)

-

Black (on white solder mask)

📝 Minimum font height: 1.0 mm (ideally 1.5 mm)

🧾 Line width: 0.15 mm minimum for clean print

🧩 Don’t forget to include the silkscreen layer in your Gerber files (usually named .GTO for top overlay, .GBO for bottom).

Before sending your PCB design for fabrication, it’s crucial to ensure the silkscreen layer is properly included in your Gerber files. If you’re not sure how to view or check this, our Gerber file beginner’s guide walks you through everything — including layer naming, common viewer tools, and how to validate your silkscreen placement.

Silkscreen Mistakes to Avoid in PCB Design

Let’s talk about avoidable mistakes we see in a lot of Gerber files:

| Mistake | Why It’s Bad |

|---|---|

| Text overlapping pads | Causes ink contamination, assembly issues |

| Font too small | Can’t read it — especially after reflow |

| No polarity indicators | Easy way to reverse a diode or LED |

| Excess text clutter | Confuses QA and repair staff |

| Omitted silkscreen layer | No guide for anyone working with the board |

Need help reviewing your files? We offer free DFM checks to catch these issues early.

Silkscreen in Prototyping and Mass Production

In prototyping, silkscreen is crucial for debugging, rework, and documentation.

In mass production, it ensures consistency, speed, and fewer human errors.

We tailor the silkscreen strategy depending on your order size:

-

Prototypes: Maximum info, flexibility

-

Volume runs: Optimized for machine readability, speed

Silkscreen PCB vs Solder Mask – What’s the Real Difference?

Here’s a quick visual to clear things up:

| Feature | Silkscreen | Solder Mask |

|---|---|---|

| Purpose | Labeling, identification | Insulation, solder bridging prevention |

| Material | Epoxy ink or acrylic-based | Epoxy resin |

| Color Options | White, black, yellow | Green, red, blue, black, etc. |

| Location | On top of solder mask | Covers copper traces |

| Functional? | No – for guidance only | Yes – protects circuits |

FAQs

1. What are the disadvantages of silkscreen printing in PCB assembly?

While silkscreen printing in PCB assembly helps with labeling and component identification, its disadvantages include limited resolution with manual screen printing, potential misalignment on small-pitch boards, and added cost for double-sided silkscreen. For precision assemblies, Direct Legend Printing (DLP) is often preferred. If you’re sourcing custom PCB silkscreen service in China, ask your vendor about print resolution, registration accuracy, and options for no MOQ PCB silkscreen to avoid surprises.

2. How thick is the silkscreen on a PCB and why does it matter?

The silkscreen thickness on a PCB typically ranges between 5 to 15 microns, depending on the printing method and ink type. Why does it matter? Excessive thickness can interfere with soldering or create clearance issues, especially on high-density boards. That's why our team double-checks the silkscreen layer in PCB design during our DFM review to ensure optimal print quality without sacrificing assembly performance.

3. What are the available PCB silkscreen colors and how do I choose?

White is the most common silkscreen color due to its high contrast on green solder mask. Other options include yellow, black, and red, often used to match branding or improve visibility. When selecting PCB silkscreen colors, consider the readability under lighting, production contrast, and even your brand identity. We offer custom PCB silkscreen with multiple ink color options — no extra charge for low-volume orders.

4. What is the difference between silkscreen and screen printing in PCB production?

In PCB production, silkscreen refers to the printed reference layer on the board surface, while screen printing is one of the methods used to apply that layer. Confused? Think of silkscreen as the result, and screen printing as one way to achieve it. Other methods include LPI and inkjet printing, which offer better precision for complex boards. Our production line uses multiple technologies depending on board specs and your PCB assembly process requirements.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary

Silkscreen on a PCB might look simple, but it plays a huge role in clarity, quality, and production speed. From identifying components to avoiding costly mistakes, it’s one layer you can’t afford to skip.

Upload your Gerber files today — we’ll help you optimize your silkscreen for smarter, faster PCB assembly.

If you’re new to the electronics manufacturing process, it’s worth reviewing the basics of how a circuit board goes from layout to production. Our beginner’s guide to PCB assembly covers essential concepts — including silkscreen, solder mask, and assembly stages — in an easy-to-follow format.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!