Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Cut-rate PCB assembly might seem like a smart budget move — until product failures, delays, and warranty claims pile up. OEMs need more than low prices. They need precision, compliance, and reliability from the start. Here’s why the lowest quote often ends up being the most expensive mistake.

Cheap PCB assembly may lower upfront costs, but it exposes OEMs to unstable quality, compliance violations, hidden rework expenses, and lack of testing support. Smart OEMs choose turnkey PCB assembly partners who provide full-stack services: from BOM validation to SMT quality control and post-solder inspection. It’s not about price — it’s about lifetime value.

Let’s look deeper into the five risks that make low-cost PCB assembly a hidden trap for OEM decision-makers — and how modern EMS providers solve them.

What is the major problem that faces circuit board manufacturing?

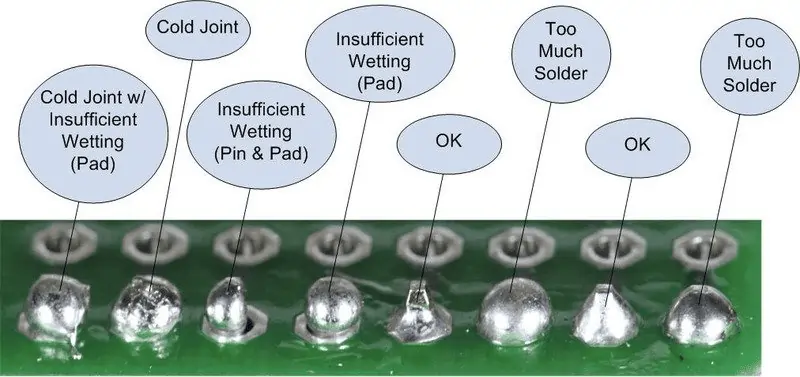

Cold solder joints, tombstoning, component misalignment, and poor stencil design — these are just a few of the failures caused by inadequate soldering and poor SMT line calibration. Improper oven profiles or unskilled technicians at low-cost vendors often result in assembly defects that are not visible until boards fail in-field.

Modern EMS providers mitigate this with:

-

Real-time AOI (Automated Optical Inspection)

-

X-ray inspection for BGA and QFN packages

-

Controlled reflow soldering processes

-

Certified IPC-A-610 workmanship standards

This level of detail is rarely — if ever — present in “budget” assembly houses.

Why Smart OEMs Avoid Cheap PCB Assembly: The 5 Hidden Risks

1. Inconsistent Product Quality & Assembly Defects

Low-end EMS providers often skip key quality control steps to cut costs. The result? Boards with solder bridges, cold joints, or even missing components. These failures may not show up during initial power-on but will emerge after thermal cycling or environmental exposure — damaging your product and reputation. Common issues like tombstoning and component misalignment often arise when vendors skip essential inspections during assembly.

High-quality providers ensure:

-

BOM cross-checking with authorized distributors

-

SMT stencil optimization based on PCB layout

-

Proper thermal profiling per solder paste specs

This reduces latent failures that otherwise trigger costly field returns.

2. Rework Costs and Lead Time Delays

Low-cost assembly is rarely truly “low cost.” Why? Because rework, shipment delays, and scrap costs quickly cancel out savings. Every return means lost time, technical investigation, and brand credibility. Low-cost quotes often omit real costs like parts attrition and sourcing markups, leading to unexpected expenses

With a reliable EMS partner, OEMs gain:

-

First-pass yield improvements through Design for Manufacturability (DFM) feedback

-

Accelerated prototyping without MOQ bottlenecks

-

Clear production traceability and serialized testing reports

These aren’t “extras” — they’re essentials in modern product development.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

3. Lack of Functional Testing and Traceability

Cheap vendors rarely offer in-house functional testing, much less boundary scan or in-circuit testing. This leaves OEMs flying blind when a fault occurs in production or field.

Smart OEMs demand:

-

Custom functional test jigs built for their PCBA

-

Complete test logs matched to serialized units

-

Root-cause reporting and corrective action plans for every detected failure

This level of traceability is what separates professional-grade assembly from cut-rate providers.

4. Compliance & IP Protection Risks

The cheaper the vendor, the more likely they skip:

-

RoHS and REACH compliance

-

ISO 9001 or ISO 13485 certifications

-

Any form of NDA or IP protection

Your board might look correct — but your certifications, legal compliance, and proprietary design are at risk.

Working with a verified EMS provider ensures:

-

Documented compliance with environmental and industry regulations

-

Secure file handling and restricted access protocols

-

Certification support for medical, industrial, and IoT products

This is non-negotiable for OEMs producing in regulated industries.

5. Limited Flexibility in Custom or Low-Volume Runs

Low-end houses often lack the ability to handle:

-

Multi-BOM builds

-

Component substitutions

-

Special testing requirements

-

Fast-turn prototyping or small-volume production

You’ll hear phrases like “We only support standard BOMs” or “No changes after Gerber upload.” That’s unacceptable when you’re iterating a high-reliability product.

Modern turnkey PCB assembly services for OEM manufacturers offer:

-

No MOQ for prototyping

-

On-demand component sourcing alternatives

-

Integrated SMT and through-hole capabilities

-

Post-soldering customization (e.g., conformal coating, potting)

This is what real flexibility looks like.

How to Choose a PCB Assembly Partner for Low-Volume Production

Choosing a PCB assembly partner isn’t just about price or location. It’s about value over time. For low-volume production or NPI (New Product Introduction), look for:

-

Engineering support during design

-

Access to authorized component distributors

-

IPC-certified assembly technicians

-

Quick DFM feedback and prototyping

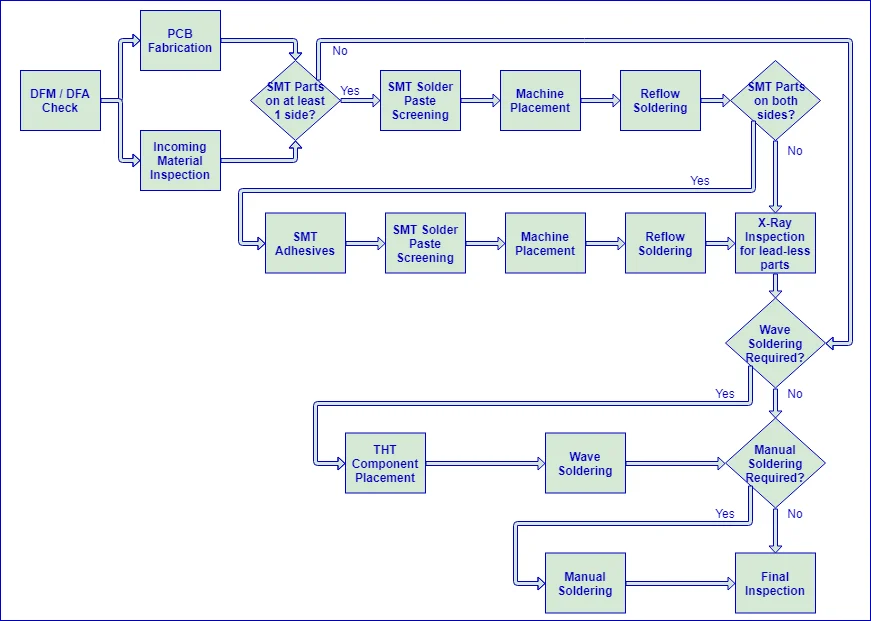

Skip providers who act like a vending machine for PCBs. You need a partner — not a printer. Before choosing an EMS provider, especially for prototyping or NPI, perform an audit of their SMT process. This step-by-step SMT factory audit guide can help you identify whether they truly meet industrial standards — or just offer a low quote.

Turnkey PCB Assembly Services for OEM Manufacturers: Why It Matters

Smart OEMs are switching to one-stop PCB assembly with component sourcing because it eliminates friction. From BOM validation to SMT and through-hole soldering, every stage is managed under one roof — reducing lead time, miscommunication, and rework.

A good EMS partner also provides:

-

Custom packaging

-

Full traceability per lot

-

Forecast-driven sourcing

It’s not just a board — it’s your product.

Industrial PCB Assembly in China with Testing and Sourcing

Not all China-based EMS providers are created equal. The myth that “cheap = Chinese” is outdated. Many industrial PCB assembly China firms specialize in:

-

B2B electronics assembly (not consumer gadgets)

-

Functional testing for gas detection, motor control, and more

-

ISO 9001/13485-certified processes

-

On-site engineers who offer real-time support

When you work with a quality-focused Chinese EMS, you gain cost efficiency with professional-grade execution — minus the risks of hobbyist platforms.

Best EMS Provider for Gas Detection and Motor Control Devices

If you’re building custom PCBA for intelligent control systems, you know how sensitive your application is. Sensor-driven boards must perform under vibration, temperature, and EMI conditions.

We specialize in:

-

High-precision SMT for analog front-end circuits

-

Conformal coating for industrial safety devices

-

Functional testing under environmental simulation

-

Quick-turn small batches with zero compromise on quality

This is where our process stands apart from cheap EMS supplier risks.

FAQs

1. What makes a reliable PCB assembly partner different from low-cost vendors?

A reliable partner offers more than just assembly — they support BOM optimization, provide real-time engineering feedback, and perform functional testing. Unlike cheap EMS supplier risks, trustworthy providers ensure consistency, compliance, and full traceability. This is crucial for OEMs building industrial or high-reliability electronics.

2. How does turnkey PCB assembly save time and reduce errors?

Turnkey PCB assembly services for OEM manufacturers consolidate sourcing, SMT placement, and testing into one streamlined process. This reduces handoffs, miscommunication, and delays — especially for low-volume or custom builds. It’s a smart way to cut lead times without sacrificing quality.

3. Why is component sourcing a major issue in low-cost PCB assembly?

Cheap PCB assembly risks often stem from sourcing counterfeit or low-grade components. These parts increase failure rates and violate compliance standards. A vetted EMS partner solves this by sourcing from authorized distributors and offering component alternatives during BOM review to ensure reliability and traceability.

4. What if my project involves both SMT and through-hole soldering?

A full-service EMS provider offers reliable PCB assembly with SMT and through-hole soldering under one roof — ideal for hybrid boards. Whether you’re building motor controllers or sensor systems, combining both techniques ensures electrical performance and mechanical durability for industrial use cases.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Functional Testing for PCB Assembly in OEM Projects

Testing isn’t a step — it’s a strategy. From in-circuit tests (ICT) to custom jig-based functional validation, functional testing for PCB assembly in OEM projects guarantees real-world readiness.

Our workflow includes:

-

Pre- and post-reflow inspection

-

Power-on/load testing

-

Serial number matching for traceability

-

Failure logging with corrective action reports

These features are mission-critical for industrial electronics reliability. A reliable EMS partner uses in-circuit testing (ICT), boundary scan, and functional validation to catch errors before they reach the field. For more on how professional-grade PCB testing works, check out these top 5 methods for high-quality PCB assembly.

Summary

Smart OEMs don’t just buy boards — they buy confidence, compliance, and long-term performance. Choose an EMS partner who understands industrial needs, not hobbyist pricing models. Let’s talk about your next build.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!