Quick Leads-PCBA

You’re ready to build a product, but finding a PCB assembly supplier who actually delivers what they promise? That’s where it gets tricky. In this guide, I’ll walk you through what really matters—no fluff, just facts and field experience.

To choose a reliable PCB assembly supplier, prioritize technical capabilities, real certifications, fast turnaround, transparent pricing, and scalable support. Look for suppliers with proven experience in your product category, quality control systems, and testing standards. Make sure they offer low-volume or turnkey PCB assembly if needed. Always verify communication responsiveness and post-sale service.

Let’s unpack what makes a PCB partner actually reliable—and how to avoid common traps that cost teams time, budget, and peace of mind.

1. What should you really look for in a PCB assembly supplier?

If you’ve ever had a project delayed by weeks due to poor assembly or last-minute BOM issues, you already know the pain. So here’s what matters up front:

-

Certifications: Look for ISO 9001, IPC-A-610, and ideally IATF 16949 for automotive work.

-

Core competencies: Are they doing both SMT and THT? Can they handle multilayer boards? HDI?

-

Vertical integration: The fewer third parties involved, the less risk of miscommunication and delay.

And of course, communication. If they take three days to respond to an RFQ, that’s already a red flag.

✅ Pro tip: Ask to see their internal QA process and photos of the production line. If they dodge the request, walk away.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

2. Why experience and scale flexibility matter more than price

We all want a good deal. But in PCB assembly, cheap often turns into expensive real fast—especially if you’re building low-volume runs or early-stage prototypes.

Here’s how different supplier types stack up:

| Feature | High-Volume Supplier | Startup-Friendly Supplier |

|---|---|---|

| MOQ Requirements | ≥ 500 pcs | No MOQ or as low as 1 |

| Flexibility with design changes | Low | High |

| Response to custom requests | Slow or resistant | Fast and collaborative |

| Support for testing/debugging | Minimal | Usually included |

| Ideal for | Mass production | R&D, pilot runs, startups |

If you’re doing small batch PCB assembly or want to avoid committing to huge runs early on, go for a PCB assembly supplier with no MOQ and strong prototyping support.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

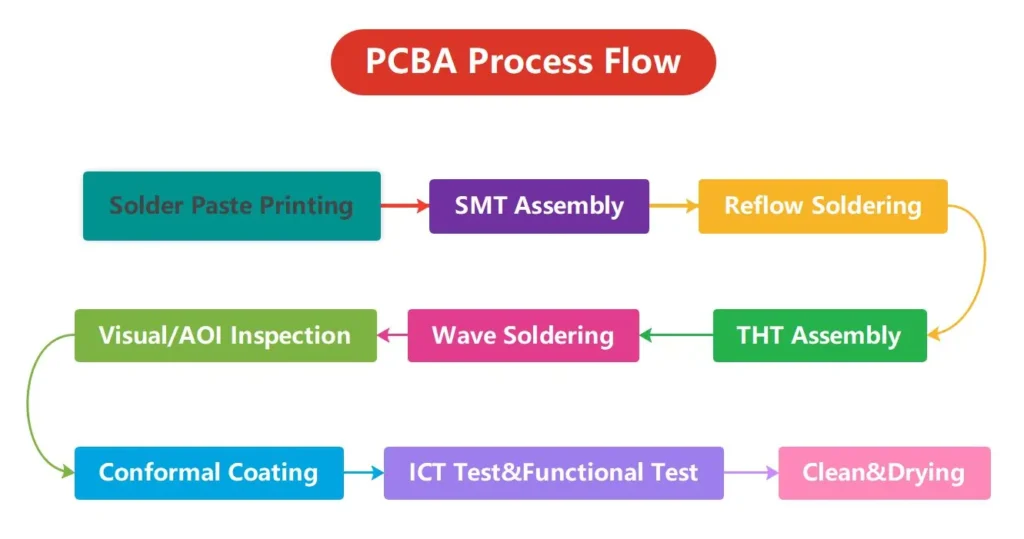

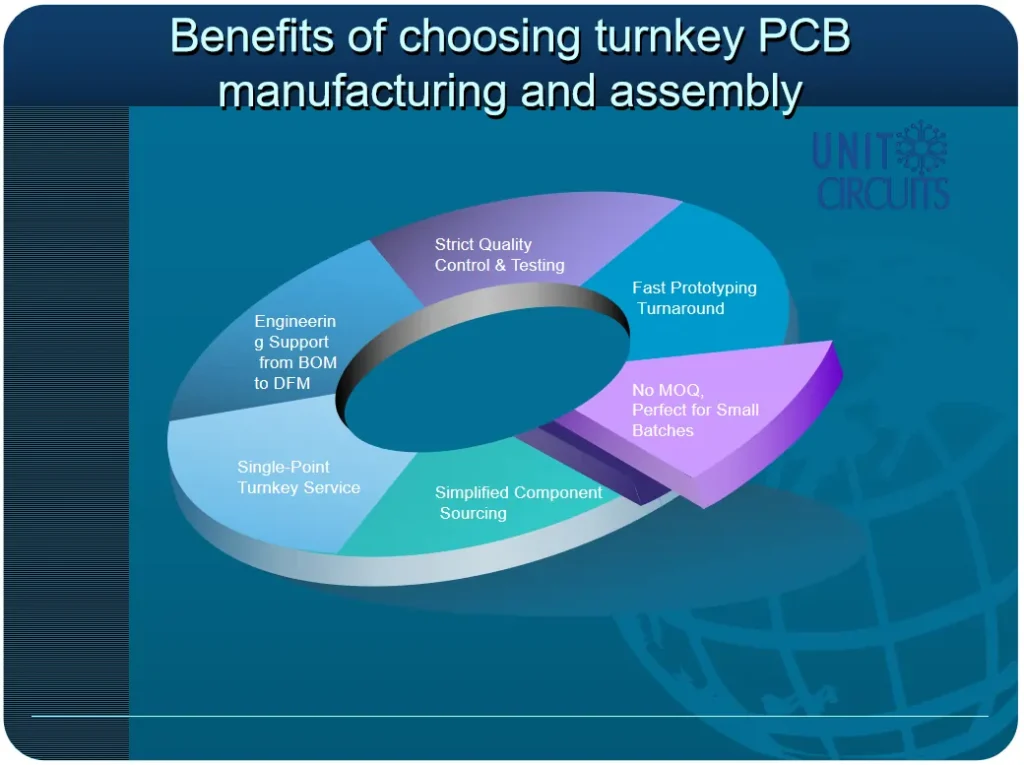

3. What does a turnkey PCB assembly service include?

This is where real time savings happen. A turnkey PCB assembly provider handles everything from sourcing components to testing the final boards. That means:

-

BOM validation and sourcing

-

PCB fabrication

-

Assembly (SMT, THT, or mixed)

-

Functional testing

-

Shipping

Here’s a quick breakdown:

| Service Area | Traditional Supplier | Turnkey EMS Provider |

|---|---|---|

| BOM Sourcing | You handle it | Included |

| Board Fabrication | Third-party required | In-house or managed |

| Assembly | Limited | Full SMT/THT/Hybrid |

| Testing | Optional or extra | Often included |

| Support Level | Minimal | Engineering support |

If you’re scaling and need fast PCB assembly services, a turnkey EMS provider in China often delivers better speed-to-market without sacrificing quality.

4. How to verify a PCB supplier’s reliability—beyond the website

You know how easy it is to polish a landing page. But what’s behind the scenes?

Here’s what I recommend:

-

Ask for sample reports: Look at previous QA/QC logs or test reports.

-

Visit or audit (virtually): Many serious suppliers will offer a factory tour—even via video.

-

Check supply chain sources: Are they getting parts from authorized distributors like DigiKey or Mouser, or taking shortcuts?

-

Look for real testing capabilities: Not just visual inspection. Ask for ICT, X-ray, or flying probe options.

5. What are PCB reliability tests, and why do they matter?

Let’s talk reliability. You’re not just assembling a board—you’re delivering a product that someone else depends on.

Here are the key PCB manufacturing and testing services that actually matter:

-

ICT (In-Circuit Testing): Tests solder joints, shorts, and opens

-

FCT (Functional Circuit Testing): Ensures the board behaves as intended

-

AOI (Automated Optical Inspection): Detects misaligned components

-

X-ray Inspection: For BGAs and complex layers

-

Environmental Testing: Temp cycling, humidity, salt spray

✅ If you’re doing PCB prototyping and assembly, make sure your supplier offers a way to scale up the same testing process for production.

Want to know which tests actually matter for different applications? This quick guide covers the top 5 PCB testing methods and how they ensure your assemblies pass both functional and stress testing before reaching production.

6. What is a realistic PCB assembly cost in 2025?

Let’s get real about pricing.To go deeper into pricing, materials, and sourcing decisions, I highly recommend checking out this guide on controlling PCB assembly costs. It breaks down 10 real-world factors that can impact your budget, especially for low- to mid-volume production runs.

Here’s a rough guide based on production volume:

| Quantity | Cost Per Unit (USD) | Notes |

|---|---|---|

| 10–100 pcs | $20 – $100 | Ideal for prototyping |

| 100–1,000 pcs | $10 – $50 | Pilot runs or pre-launch builds |

| 1,000–10,000 pcs | $5 – $30 | Scaling phase |

| 10,000+ pcs | $2 – $20 | Full production |

Keep in mind:

-

Prices vary by board complexity, layer count, and component types.Here’s a deeper breakdown of PCB cost estimation from Altium.

-

Low-volume PCB manufacturing is more cost-efficient when bundled into turnkey services.

And yes, you can still get PCB assembly services with no MOQ, but expect to pay slightly more per unit in exchange for speed and flexibility.

7. How to choose an EMS provider who gets your product (and your pain points)

One of the biggest problems I see? Suppliers who just don’t “get it.” They’ll assemble what you send, but don’t contribute anything else. That’s not a partnership—it’s a transaction.

Instead, look for someone who:

-

Suggests improvements to your layout or BOM

-

Flags potential DFM issues

-

Offers help with sourcing alternatives when components are EOL

-

Thinks beyond just the PCB (like enclosures, integration, or certifications)

Ask yourself:

Does this supplier understand the type of product I’m building?

Do they regularly work with clients in my industry?

Whether you’re a startup or scaling up, a good EMS provider is proactive, not reactive.

Bonus: Looking for a PCB supplier for Canada or the UK?

We often get clients from Canada and the UK who want to outsource PCB assembly to Asia but keep logistics clean and fast.

What works:

-

Look for suppliers offering dedicated shipping lanes or customs-ready paperwork

-

Use regional support reps or timezone-aligned project managers

✅ If you’re sourcing for UK or Canada, ask your EMS provider if they offer DDP (Delivered Duty Paid) options—it simplifies everything.

Reliable suppliers usually require a standardized BOM for accurate quoting.

FAQs

1.Why is PCB assembly so expensive?

PCB assembly can seem expensive because it involves multiple high-precision processes—like solder paste application, pick-and-place, reflow soldering, and testing. Costs go up with low-volume PCB manufacturing, tight tolerances, or rare components. If you're looking to reduce costs, consider a PCB assembly supplier with no MOQ or a turnkey PCB assembly service that handles sourcing and testing in one streamlined process.

2.How to choose a PCB manufacturer that fits your product?

To choose a reliable PCB supplier, focus on experience with your specific product type, available PCB manufacturing and testing services, and their ability to scale from prototype to production. Ask about certifications, communication flow, and DFM support. If you're a startup, look for the best PCB assembly for startups—someone who offers flexibility and fast feedback loops.

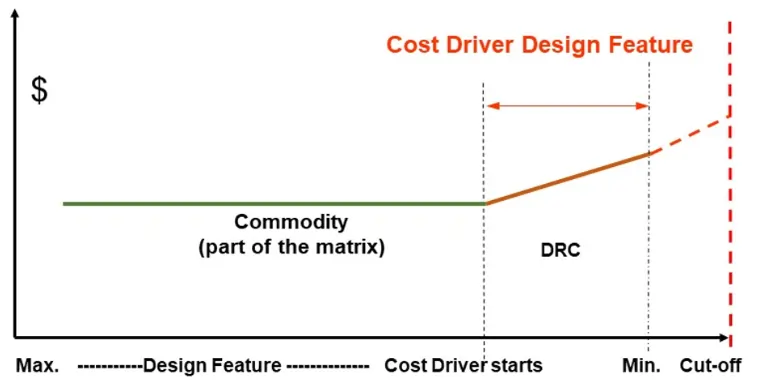

3.What are the main factors affecting PCB manufacturing cost?

Key cost drivers include board size, layer count, materials (e.g., FR4, Rogers), and component sourcing. Tighter tolerances, controlled impedance, or special finishes also raise costs. If you need fast PCB assembly services without overpaying, choose a turnkey EMS provider in China who can handle sourcing and assembly efficiently in-house.

4.What PCB testing methods should a good supplier offer?

At minimum, a reliable PCB supplier should provide AOI (Automated Optical Inspection), ICT (In-Circuit Testing), and FCT (Functional Circuit Testing). For complex boards, X-ray and environmental tests (like thermal cycling) are critical. When comparing suppliers, make sure their PCB manufacturing and testing services include the right mix for your product’s reliability needs.

If you’re designing for reliability and cost control, Altium offers great insights on PCB testing and cost drivers.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Summary

Picking the right PCB assembly partner isn’t just about checking boxes. It’s about finding a team who can build what you’ve imagined—flawlessly. If you’re looking for fast, no-MOQ, and reliable PCB services, I’d be happy to walk you through how we can help.

Want to chat about your project?

Whether you’re prototyping or ramping to production, shoot me a message. I’ve worked with everyone from hardware startups to IoT manufacturers—let’s see what we can build together.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!