Quick Leads-PCBA

Struggling to find a dependable PCB partner without overcommitting to high-volume orders? Engineers often face long lead times, hidden costs, or minimum quantity traps. You need a solution that scales with your innovation, not against it. Here’s how custom PCB prototyping has finally caught up with your pace.

A custom PCB prototype service with no MOQ, fast turnaround, and low cost provides engineers with the flexibility to test designs without over-ordering. These services include rapid PCB fabrication, SMT assembly, quality inspection, and express shipping. Reliable providers support Gerber files, same-day PCB runs, and defect tracking—ideal for startups and hardware development.

Let’s dive deeper into the biggest industry challenges and how modern PCB solutions are eliminating them with speed, affordability, and precision engineering.

What is a custom PCB prototype and why is it essential in modern product development?

A custom PCB prototype is a preliminary version of a printed circuit board built to your exact specifications. It’s used to test electrical and mechanical functionality before moving to full-scale production. For engineers working on IoT devices, robotics control boards, or even gas detector PCBs, this early-stage validation is critical.

Using a custom prototype allows teams to:

-

Validate layout and component choices

-

Detect design flaws early

-

Perform real-world functional testing

-

Iterate without financial risk

Modern prototyping services even include one-stop PCB manufacturing and assembly service, reducing friction from design to testing.

Industry Pain Points: What Makes PCB Prototyping So Challenging?

Before recent advancements, sourcing PCB prototypes was notoriously complex. Here are key issues engineers and product teams often faced:

1. Minimum Order Quantities (MOQ):

Legacy manufacturers enforced high MOQs, making it expensive to test small batches or single revisions.

2. Long Lead Times:

Typical turnaround times could stretch from 7 to 14 days, delaying iteration cycles.

3. Lack of Design Flexibility:

Rigid process requirements and limited support for complex Gerber files or multilayer boards made prototyping risky.

4. Hidden Costs:

Setup charges, tooling fees, and shipping costs often weren’t transparent upfront.

5. Limited Technical Support:

Many vendors didn’t offer DFM analysis, leading to rejections or delays once files were submitted.

How Our Custom PCB Prototype Service Solves These Problems

Our service model is built around eliminating each of the major pain points identified above:

-

No MOQ PCB Manufacturing: Whether you need 1 or 100 boards, we can fulfill it. This is perfect for startups, R&D labs, or small product runs.

-

Fast PCB Prototyping Service: Choose from 24- or 48-hour turnaround options, with express shipping available globally.

-

Turnkey PCB Assembly: We handle sourcing, SMT assembly, and inspection—all in-house.

-

Real-Time Quote & DFM Check: Upload your Gerber files, BOM, and pick-place data for instant analysis and feedback.

-

IPC-A-610 Standard Compliance: We guarantee precision manufacturing and low defect rates.

This makes our service ideal for clients seeking quick turn PCB prototype service or even no MOQ PCB assembly in China and we handle the entire process with a full turnkey PCB assembly approach, from fabrication to shipping.

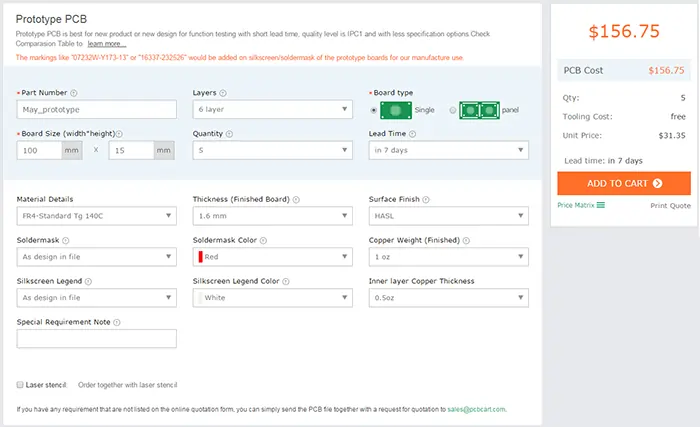

How much does PCB prototyping cost today?

Pricing has improved drastically thanks to advanced automation and scale. Today, low-cost PCB prototype services can start from as little as $5–$10 for simple two-layer boards (50mm x 50mm). Here’s what influences cost:

-

Board Dimensions

-

Number of Layers (e.g., 2-layer vs. 6-layer)

-

Material Selection (e.g., FR-4, Rogers)

-

Surface Finish (HASL, ENIG)

-

Turnaround Time (standard vs. express)

For startups, we offer affordable prototype PCB for hardware development without sacrificing reliability.

PCB pricing is affected by several key factors beyond just board size or layer count. If you’re aiming to keep costs low, understanding the full cost breakdown is critical.

Here’s a practical guide to controlling PCB assembly costs across 10 critical factors without sacrificing quality or reliability.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Cheap PCB prototyping with fast shipping: Is it reliable?

Many assume “cheap” equals poor quality—but that’s a myth. We balance affordability with quality by:

-

Using automated optical inspection (AOI) and functional testing

-

Adhering to IPC standards for soldering and trace spacing

-

Offering express PCB delivery options with trusted carriers

We also track and reduce our defect rate through stringent internal QA processes.

Affordability doesn’t mean skipping critical validation. To ensure board performance, we apply multiple inspection layers during and after assembly. Learn more about the top 5 testing methods used in high-quality PCB assembly, including ICT, functional tests, and visual inspections.

Technical Overview: SMT Assembly, Gerber Files & Functional Testing

Technical performance matters—especially for advanced engineers. Here’s how we ensure high standards:

-

Gerber File Validation: Our system automatically checks for shorts, opens, and trace violations.

-

Solder Paste Stenciling: We use laser-cut stencils for accurate paste deposition.

-

SMT Assembly: Our pick-and-place machines support 0201 components and fine-pitch ICs.

-

Reflow Ovens: Multiple thermal profiles accommodate lead-free and specialty components.

-

Functional Testing: Powered tests verify voltage levels, clock signals, and I/O behavior on request.

What are the benefits of no MOQ PCB manufacturing?

Going with a no MOQ PCB manufacturer has distinct advantages:

-

Cost Control: Order only what you need.

-

Design Iteration: Test revisions without financial penalty.

-

Speed to Market: Launch faster with flexible production planning.

-

Ideal for Prototyping: Especially useful for early-stage products and MVPs.

This makes it popular among teams seeking a custom PCB prototype service for startups.

Quick turn PCB prototype service: What’s realistically possible?

With optimized production lines and express handling, we offer:

-

Same-day PCB runs for simple designs

-

24-hour fabrication turnaround

-

48-hour assembly completion

-

Global delivery with DHL, FedEx, and SF Express

This is crucial for teams managing tight launch windows or investor demo schedules.

Who should choose our affordable prototype PCB for hardware development?

Our services are ideal for:

-

Hardware Startups needing to show functionality fast

-

R&D Teams in need of weekly revisions

-

Academic Institutions prototyping student or lab projects

-

OEMs looking to validate sub-circuits for larger systems

We also support niche applications like IoT PCB, robotics, and sensor boards.

Why Choose a China Custom PCB Prototype Supplier?

There are strong benefits to working with a China-based PCB prototype supplier like us:

-

Competitive Pricing: We minimize production costs through volume and automation

-

Scalable Infrastructure: From 1 to 10,000 units without switching vendors

-

Skilled Technicians: In-house engineers assist with layout and DFM

-

End-to-End Services: PCB design, fabrication, and SMT assembly—all under one roof

-

Multilingual Support: English-speaking teams for customer service and tech support

We’re not just a custom PCB builder—we’re a manufacturing partner.

FAQs

1. How can I reduce the cost of PCB prototyping without sacrificing quality?

To cut PCB costs while maintaining reliability, start by simplifying your layer count and choosing standard board sizes and materials. Opt for a low-cost PCB prototype service that offers in-house DFM checks and consolidated assembly. Vendors specializing in economical PCB prototyping with quality inspection and IPC compliance help balance performance with budget.

2. Can I design my own PCB and still use a turnkey PCB assembly service?

Absolutely. Most turnkey PCB assembly providers allow you to upload your own Gerber files, BOM, and pick-and-place data. This lets you retain full control over design while outsourcing fabrication and assembly. Look for a custom PCB prototype service for startups that supports DIY layouts and offers pre-assembly feedback to minimize design errors.

3. How long does it take to design and prototype a custom PCB?

Designing a basic PCB can take 1–3 days depending on complexity. With a quick turn PCB prototype service, your fabricated and assembled board could be delivered in as little as 24–72 hours. Choose a supplier that supports express PCB delivery, no MOQ, and same-day PCB runs to accelerate your development timeline.

4. What’s the difference between PCB and PCBA—and why does it affect cost?

A PCB (Printed Circuit Board) is just the bare board, while PCBA (PCB Assembly) includes all mounted components. PCBA costs more due to component sourcing, SMT assembly, and testing. To optimize your budget, select a one-stop PCB manufacturing and assembly service offering bulk discounts, streamlined sourcing, and low-cost PCB prototyping with fast shipping.

It’s important to understand the full scope of PCBA services versus a bare PCB. If you’re unclear on what each includes, this breakdown of the difference between PCB and PCBA will clarify why assembly costs vary—and why integrated services save time.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion: Ready to Launch Your Next PCB Project?

Finding a trusted custom PCB prototype service doesn’t have to be a gamble. With zero MOQ, fast shipping, and turnkey solutions, you’re free to test, tweak, and scale without compromise. Let’s bring your next innovation to life—efficiently and affordably.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!